Temperature sensor based on resistance measuring, and radiant heater provided with a temperature sensor of this type

A temperature sensor and resistance measurement technology, applied in the field of radiant heating bodies, can solve the problems of slow response to temperature changes, spending a lot of energy, etc., and achieve the effect of good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

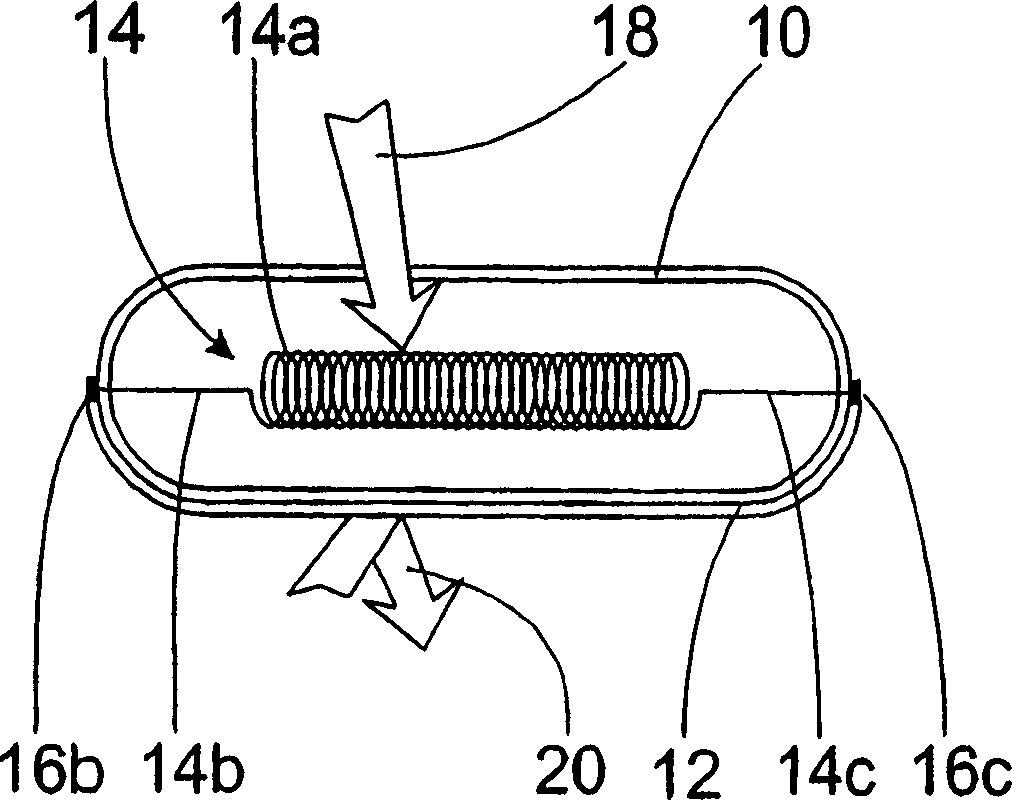

[0033] figure 1A temperature sensor according to the invention is shown which has a tubularly extending housing 10 . Both ends of the case 10 are closed, so the whole is hermetically sealed. One side of the casing has a reflective layer 12 . No heat radiation penetrates into the housing on this side. Inside the housing 10 , a sensor element 14 is arranged parallel to the main extension direction of the housing 10 . The sensor element 14 has a coil 14a and two lead wires 14b, 14c. Leads 14b, 14c are led out of the housing at the ends of the housing and are connected to connection contacts 16b, 16c of the temperature sensor.

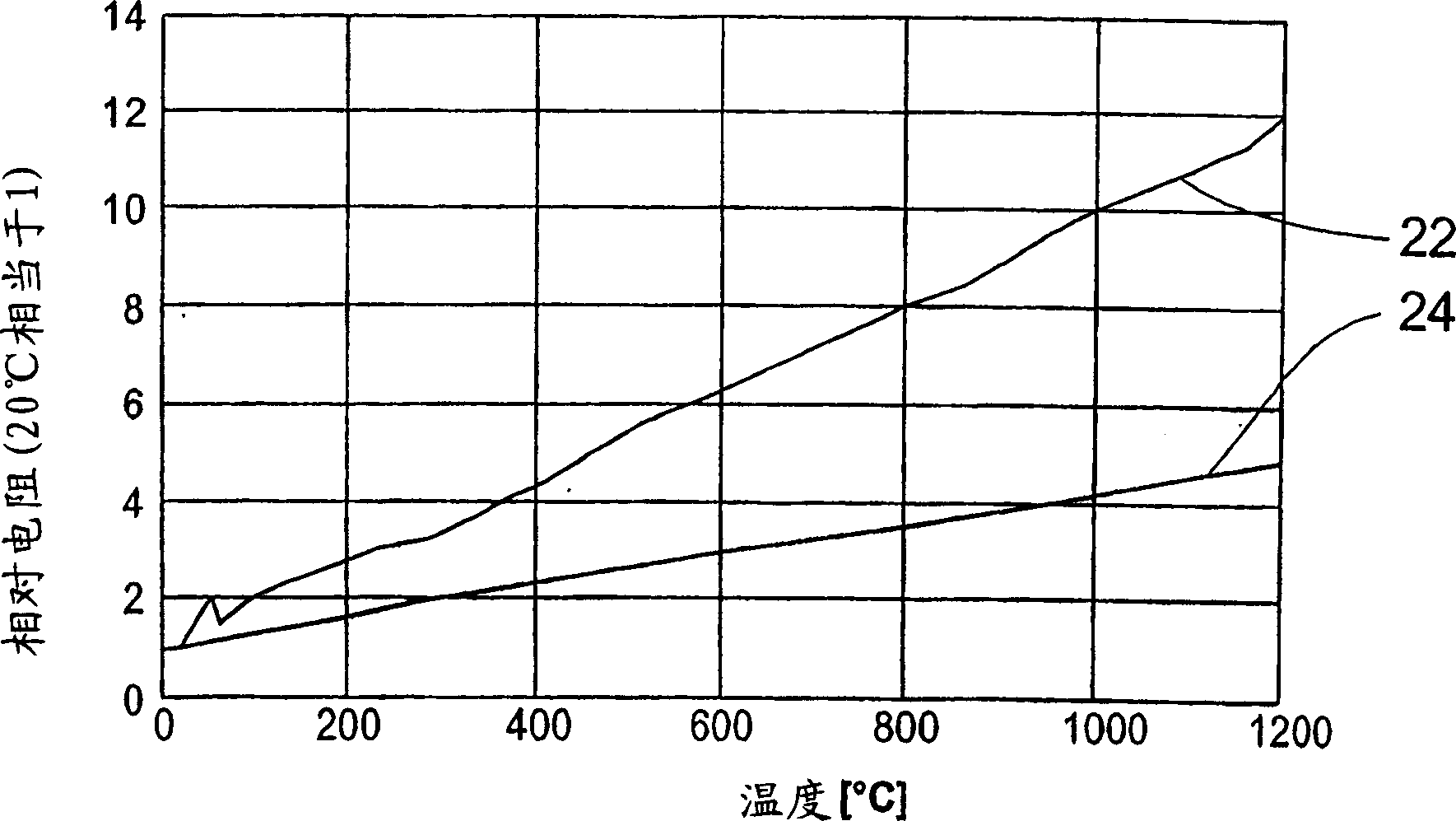

[0034] The heat radiation 18 reaches the housing 10 on the non-reflecting side, enters the housing 10 and heats the sensor element 14 there, in particular the heating coil 14a. Due to the positive temperature coefficient characteristic of the coil 14a, the resistance increases with temperature, and the measurement of the voltage and the current intens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com