Corrugated-type board automatic welding machine

A technology of automatic welding machine and corrugated plate, applied in the direction of welding rod characteristics, welding equipment, arc welding equipment, etc., can solve the problems of uneven penetration of weld bead, easy deviation of weld bead, high welding requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The corrugated plate automatic welding machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

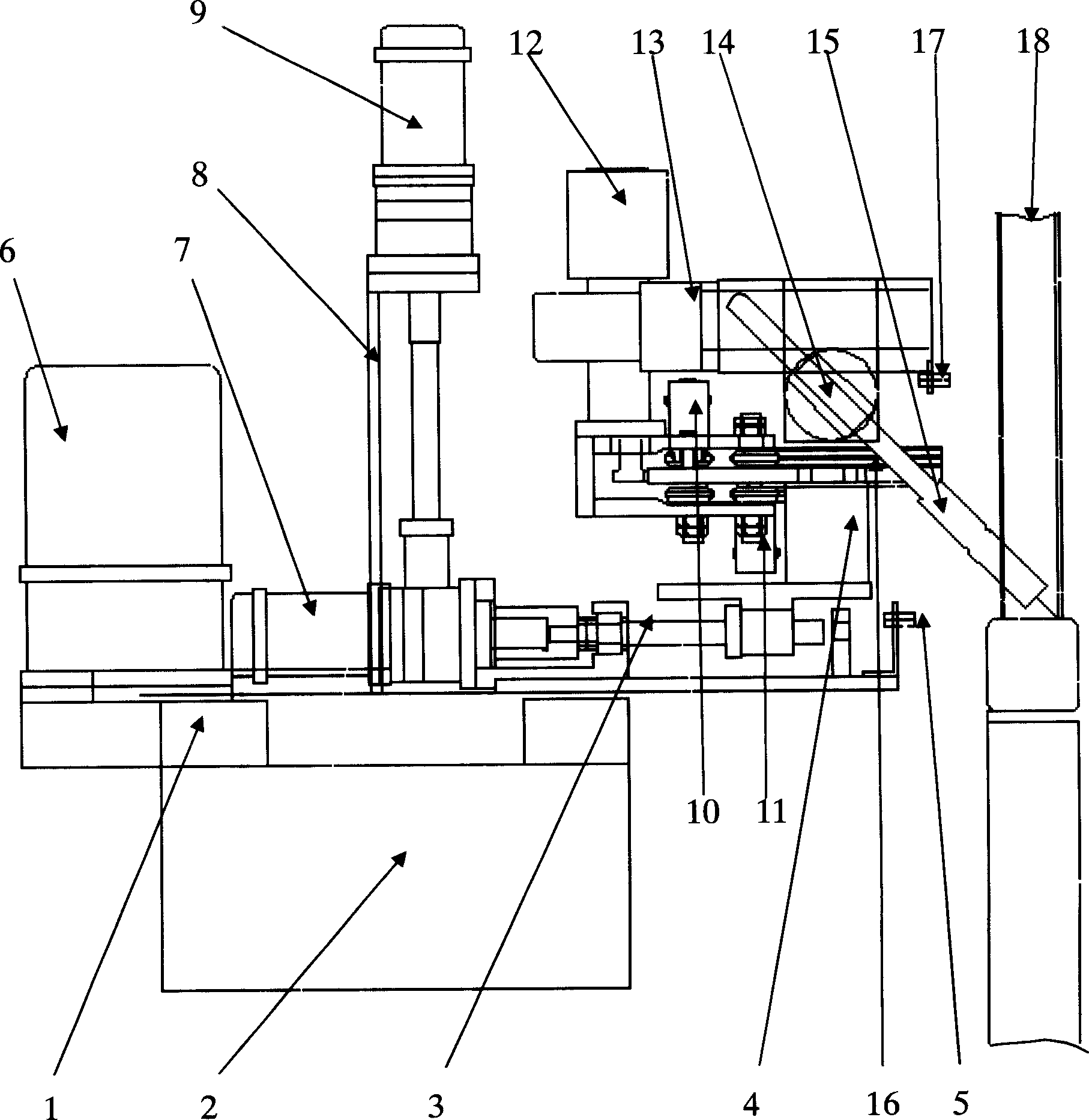

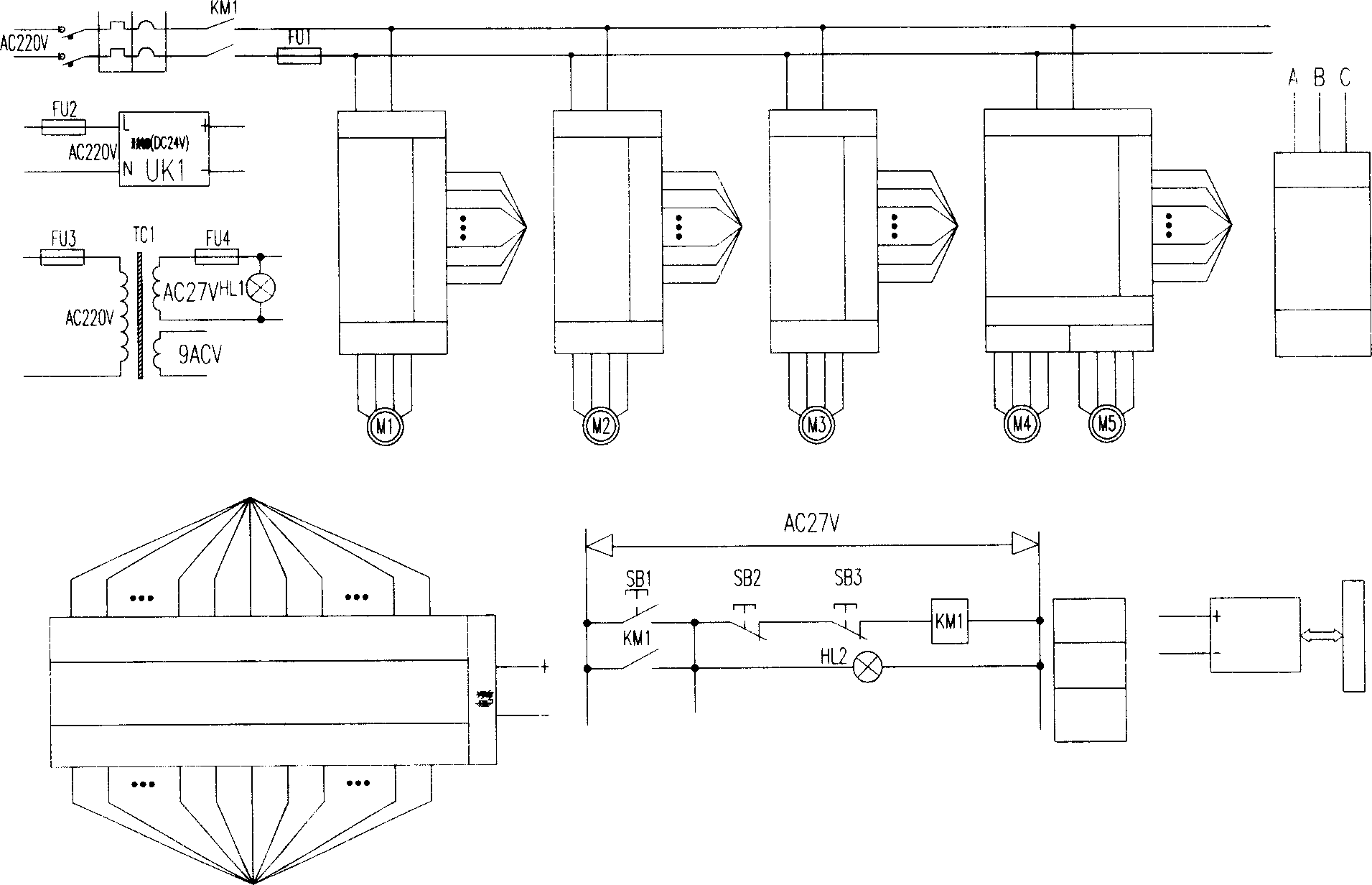

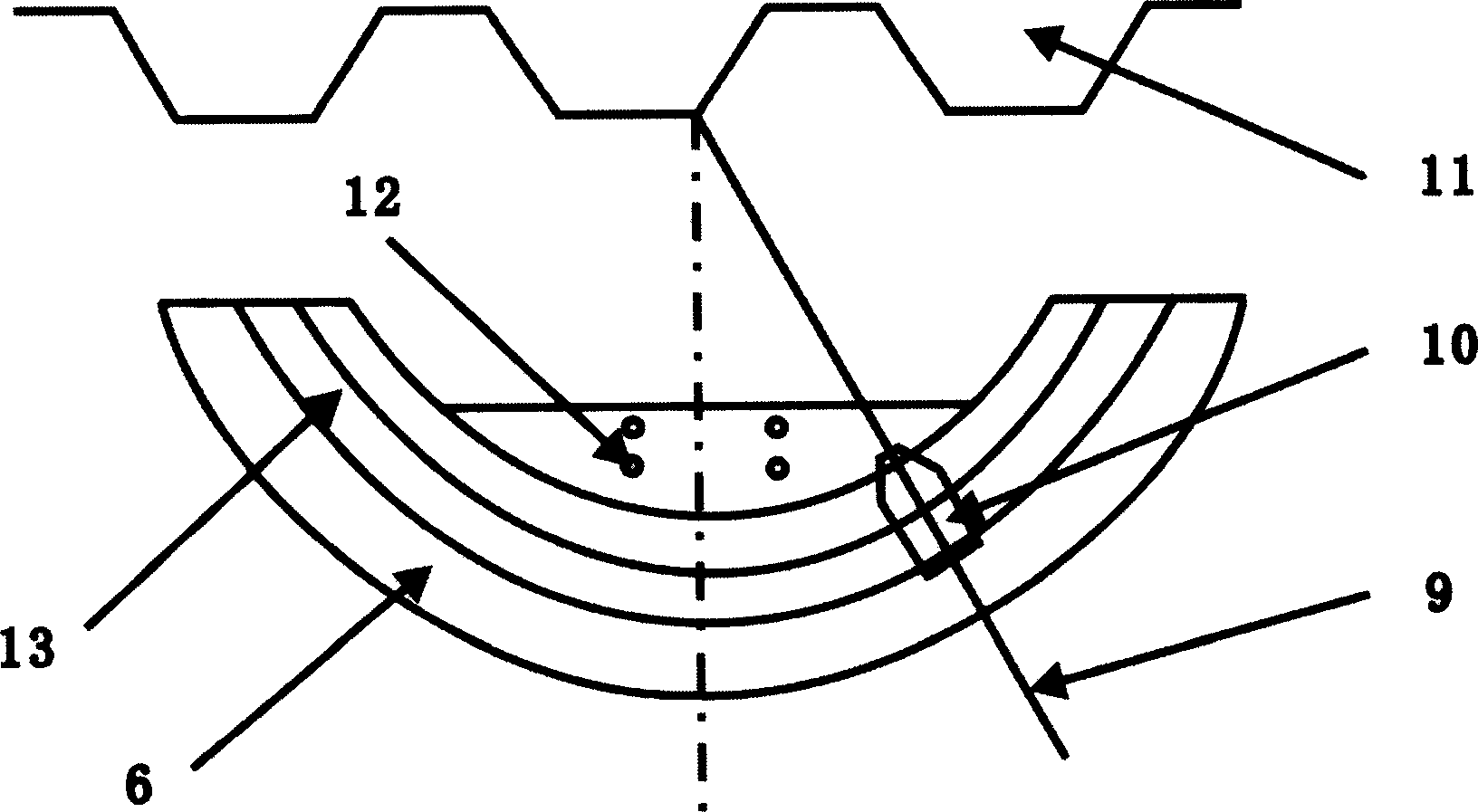

[0035] figure 1 It is the structural representation of the corrugated plate automatic welding machine provided by the present invention, image 3 It is a structural schematic diagram of the welding torch swing angle mechanism of the corrugated plate automatic welding machine provided by the present invention, wherein 1, long axis, 2, movable trolley, 3, short axis, 4, base (support), 5, vertical tracking probe , 6. Long-axis drive motor, 7. Short-axis drive motor, 8. Fixed backplane, 9. Vertical tracking motor, 10. Balance wheel device, 11. Guide wheel device, 12. Rotary motor, 13. Horizontal row surface tracking Motor, 14, welding torch holder, 15, welding torch, 16, arc-shaped rotary disk, 17, horizontal tracking probe, 18, workpiece, 19, circular arc-shaped track, 20, fixing hole, this corrugated plate au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com