Encapsulating material and method for making same

A technology of packaging materials and fillers, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low initial viscosity, easy cracking, high initial viscosity, etc., and achieve the effect of improving wettability and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

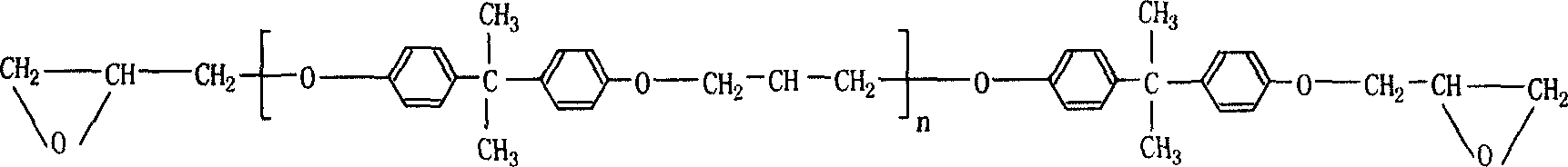

Image

Examples

preparation example Construction

[0017] The preparation method of the encapsulation material provided by the present invention includes dissolving the coupling agent in a solvent, adding fillers, dispersing uniformly and removing the solvent, and then mixing the obtained product with epoxy resin and curing agent uniformly. According to the preparation method of the packaging material provided by the present invention, the dispersion time is 10-100 minutes. The solvent can use any solvent that can dissolve the coupling agent but does not react with the filler or the coupling agent and is easily removed, such as alcohols and ketones. Preferably, it is acetone, methanol, methyl ethyl ketone, ethanol, or a mixture thereof. The amount of solvent used only needs to make the coupling agent and filler uniformly dispersed, for example, the weight of the solvent is 10-100 times that of the coupling agent. The solvent can be removed by any method in the prior art, such as vacuum drying, natural drying, blast drying, etc., p...

Embodiment 1

[0024] This embodiment is used to illustrate the packaging material and its preparation method of the present invention.

[0025] Dissolve 12 parts by weight of γ-(methacryloyloxy)propyltrimethoxysilane in 300 parts by weight of acetone, add 100 parts by weight of silicon powder with an average particle size of 15 microns to it, disperse for 80 minutes, and leave to stand. After 30 hours, vacuum dry (vacuum degree is 0.06 MPa).

[0026] 108 parts by weight of the above-treated silicon powder, 16 parts by weight of cyanoguanidine, 15 parts by weight of dibutyl phthalate, and 8 parts by weight of 2,4,6-(N,N-dimethylaminomethyl ) Phenol was added to 100 parts of bisphenol A epoxy resin (epoxy equivalent of 184, number average molecular weight of 500), mixed uniformly, vacuum degassing (vacuum degree of 0.06 MPa) to obtain packaging material A1.

Embodiment 2

[0028] This embodiment is used to illustrate the packaging material and its preparation method of the present invention.

[0029] Dissolve 2 parts by weight of γ-aminopropyltriethoxysilane in 200 parts by weight of acetone, add 60 parts by weight of silicon powder with an average particle size of 75 microns to it, disperse for 40 minutes, leave it for 18 hours, and then vacuum dry Dry (vacuum degree is 0.05 MPa).

[0030]Add 62 parts by weight of the above-treated silicon powder, 8 parts by weight of cyanoguanidine, and 5 parts by weight of tributyl phosphate to 100 parts of bisphenol A epoxy resin (epoxy equivalent 240, number average molecular weight 750), and mix Uniform, vacuum degassing (vacuum degree is 0.05 MPa) to obtain packaging material A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com