Laser reparation method for organic el element and laser reparation device

A repair method and component technology, applied in the direction of organic semiconductor devices, electrical components, measuring devices, etc., can solve problems such as pixel loss of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

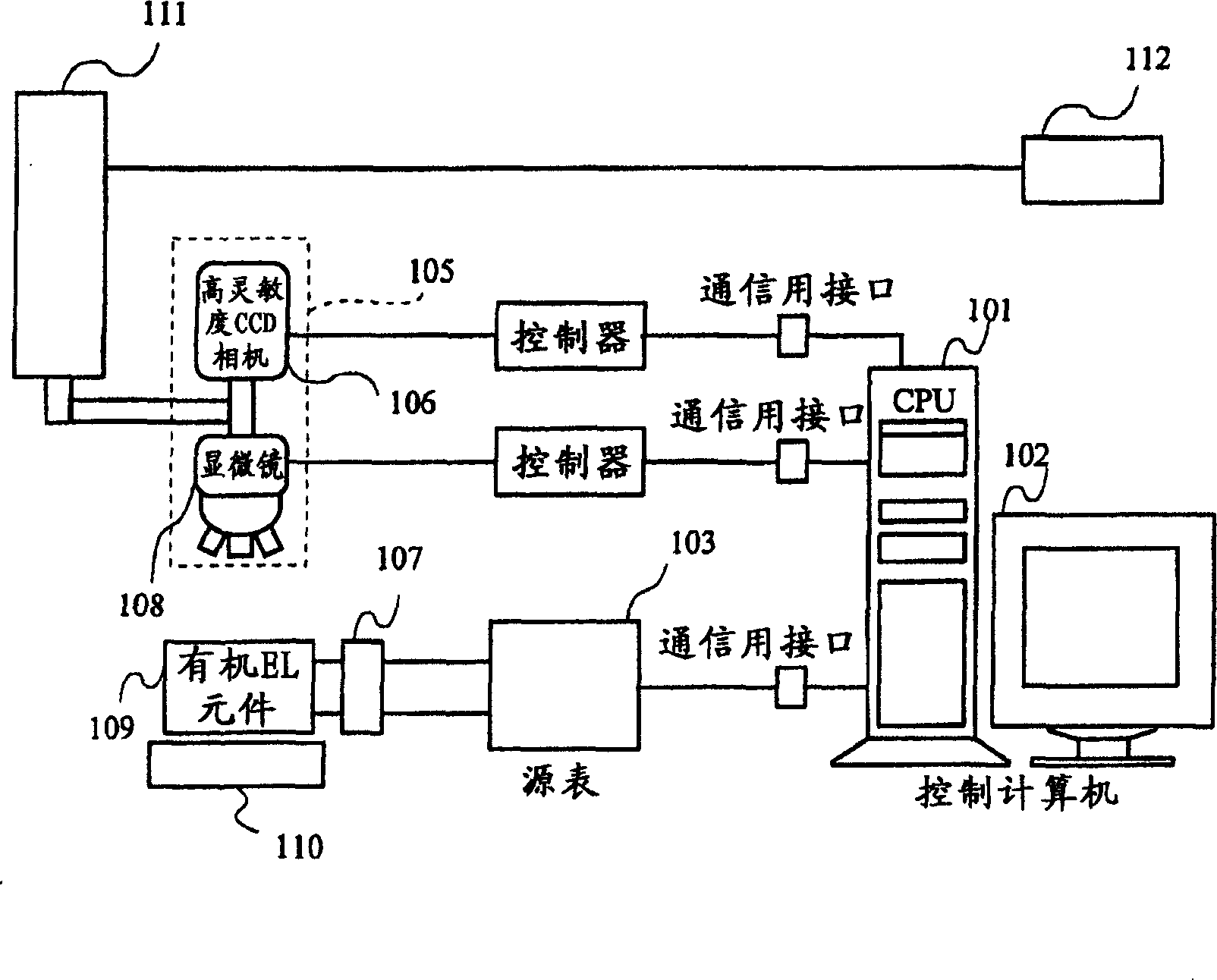

[0048] figure 1 It is a block diagram showing the configuration of the inspection device according to Embodiment 1 of the present invention.

[0049] The inspection device according to Embodiment 1 of the present invention includes a control computer 101 , a display device 102 , a holder 110 , a probe 107 , a source meter 103 , a camera 105 , a laser irradiator 111 , and a laser adjuster 112 . The control computer 101 controls the display device 102 , the holder 110 , the probe 107 , the source meter 103 , and the camera 105 . The organic EL element 109 to be repaired is placed on the holder 110 and electrically connected to the source meter 103 through the probe 107 . The source meter 103 is controlled by the control computer 101 and applies a commanded voltage to the organic EL element 109 through the probe 107 . Also, the source meter 103 is controlled by the control computer 101 , measures the voltage and current characteristics of the organic EL element 109 , and sends ...

Embodiment approach 2

[0056] The restoration method according to Embodiment 2 of the present invention will be described below.

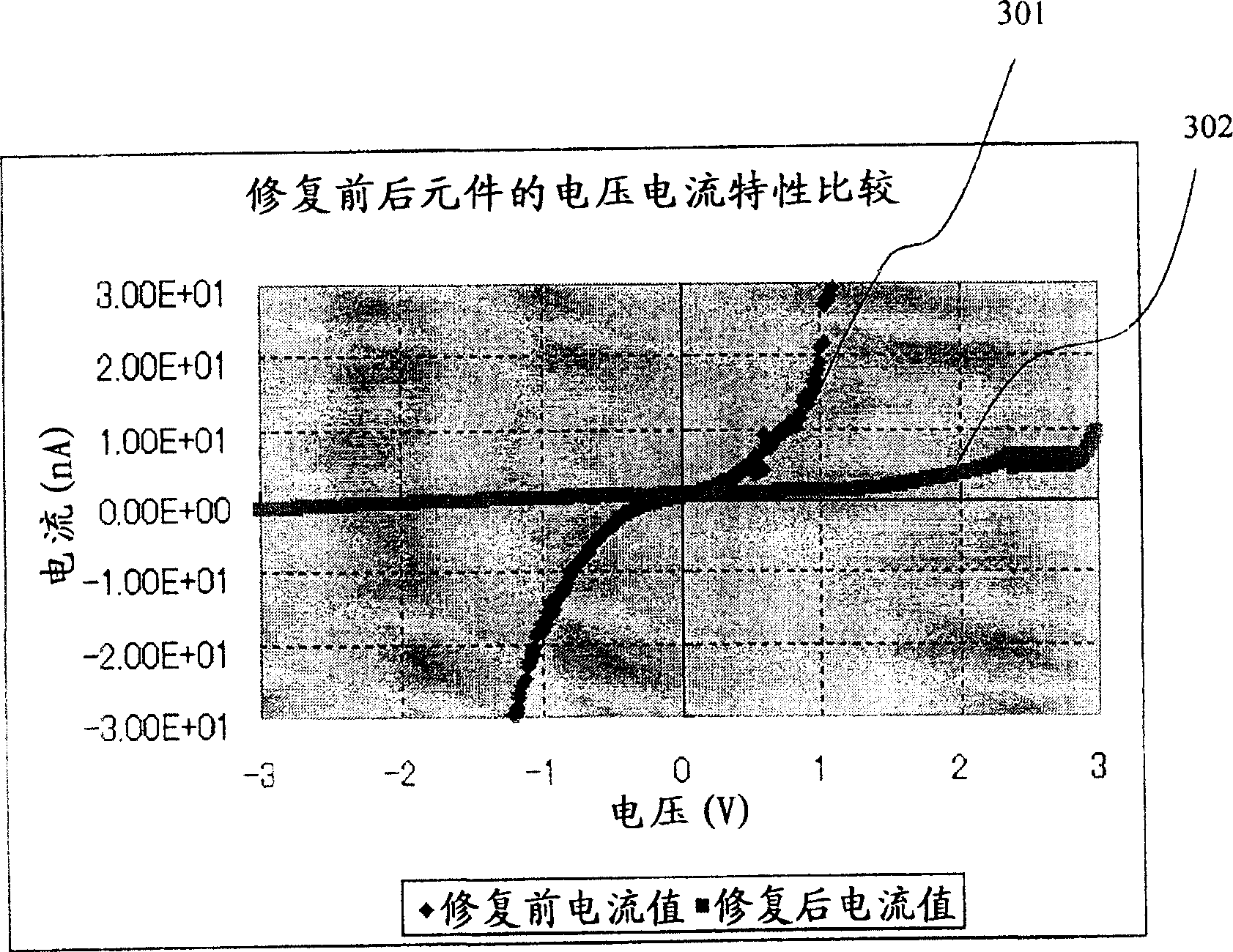

[0057] Figure 4 It is a flowchart showing the restoration method according to Embodiment 2 of the present invention. Refer to below Figure 4 and figure 1 side to explain. First, the organic EL element to be repaired is set on the holder 110, the voltage-current characteristic of the organic EL element 109 is obtained by the source meter 103, and the voltage-current characteristic is compared with a reference voltage determined based on the voltage-current characteristic of a normal organic EL element. The current characteristics are compared to determine whether or not a so-called leakage current flows in the organic EL element to be repaired, and obtain a leakage current value (S401). When there is a leakage current here, it can be considered that there is a high possibility that some kind of defective region exists in the organic EL element to be repaired.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com