Construction method of immersed tube club-footed bored concrete pile

A technology of bottom-expanding cast-in-place pile and construction method, which is applied in the construction field of sinking-tube bottom-expanding cast-in-situ pile, can solve the problems that hammering cannot reach free fall, low sinking speed, and slow sinking speed, etc., and can reach the applicable soil layer Wide, strong ability of immersed tube, fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

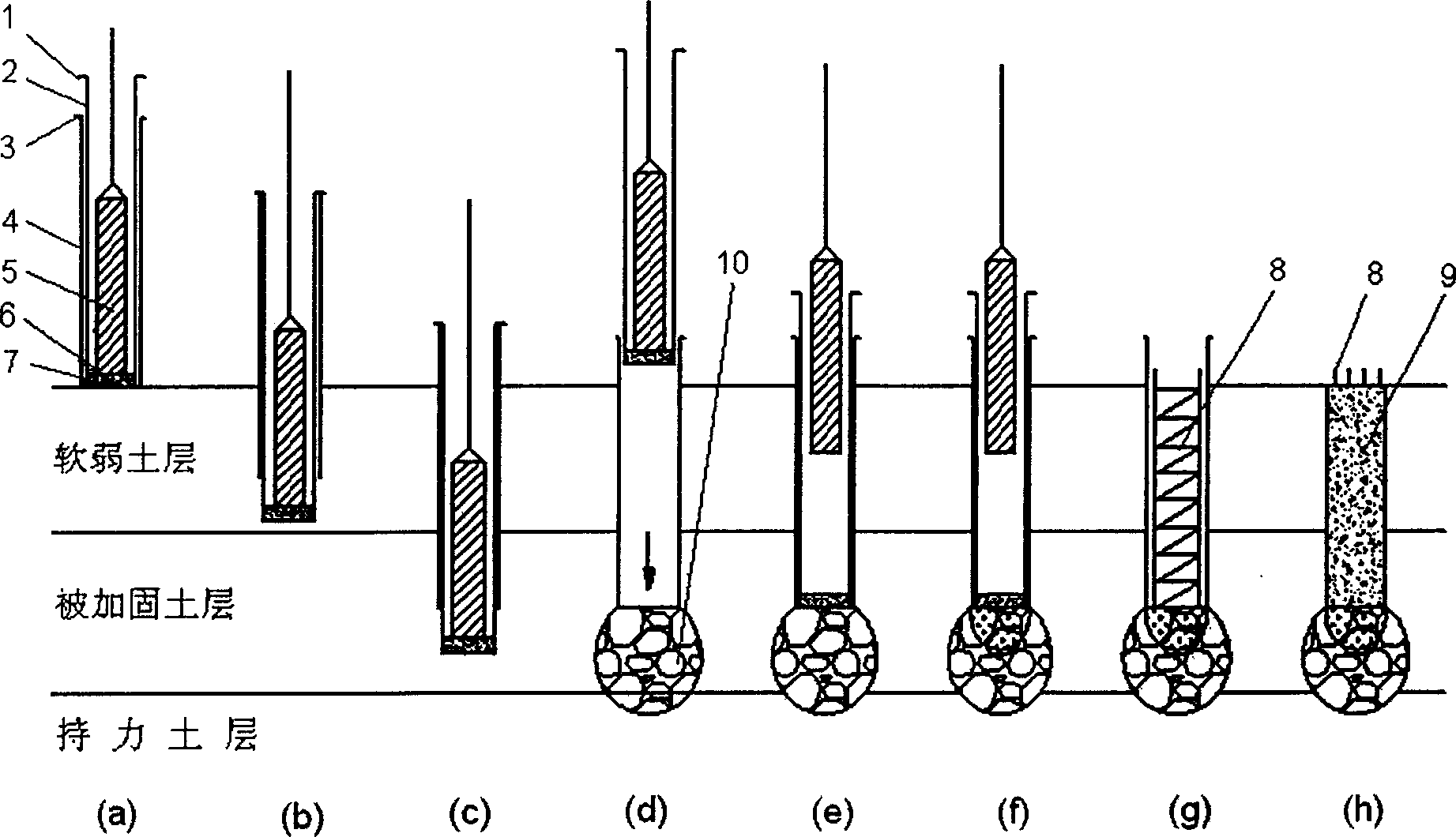

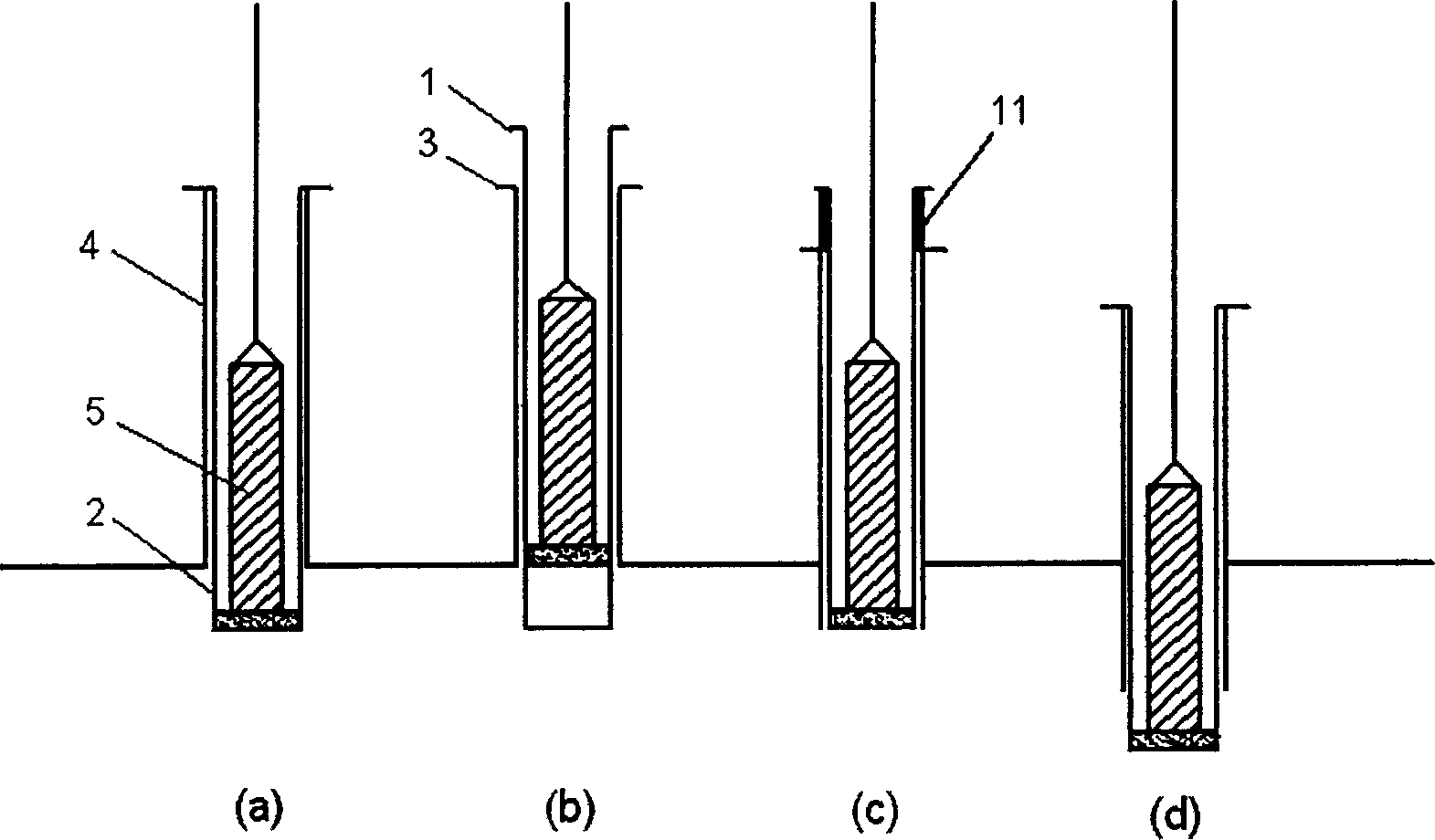

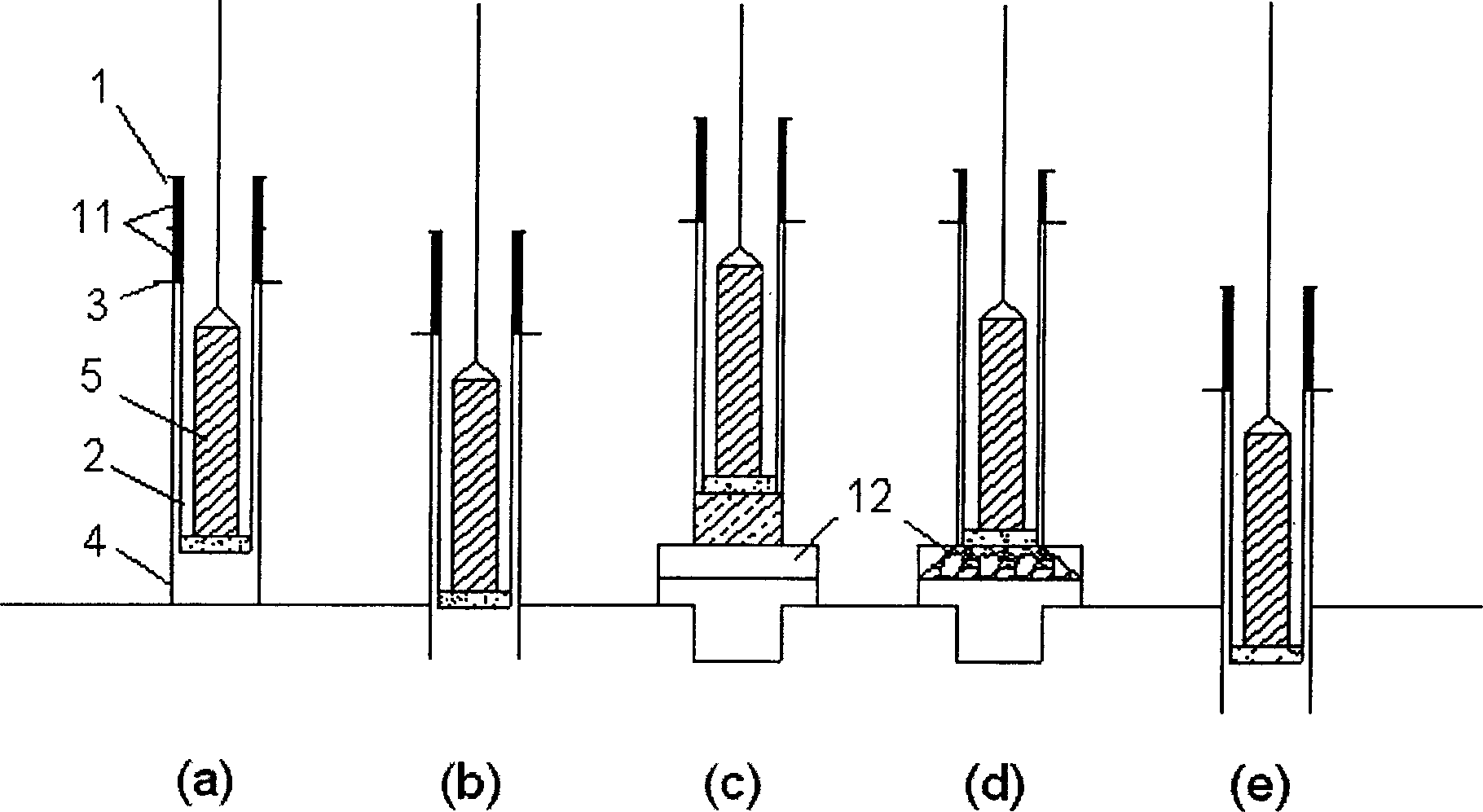

[0030] Such as figure 1 As shown, what adopts is the double-tube structure formed by the internal ramming tube 2 whose length is larger than the outer pile tube 4 in the clearance of the through outer pile tube 4. The bottom end of the inner ramming tube 2 is a detachable and replaceable The prefabricated closed structure 7 is pre-installed with an appropriate amount of solid fillers 6 such as coarse sand and gravel. The closed structure 7 can be selected as a tapered outer end or a flat-bottomed outer end according to construction requirements. The tops of the inner ramming tube 2 and the outer pile tube 4 are respectively provided with limiting structures 1, 3 in the form of mutually cooperating limiting rings and the like.

[0031] When the submerged soil layer is relatively weak, the side resistance and end resistance are small during the immersed tube process, and the side resistance and end resistance can be overcome at the same time. When hammering its bottom in the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com