Small inert IE grade platinum resistance thermometer

A platinum resistance and thermometer technology, applied in the field of small inert IE grade platinum resistance thermometers, can solve the problems of insufficient strength, long thermal response time, etc., and achieve the effect of small thermal response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

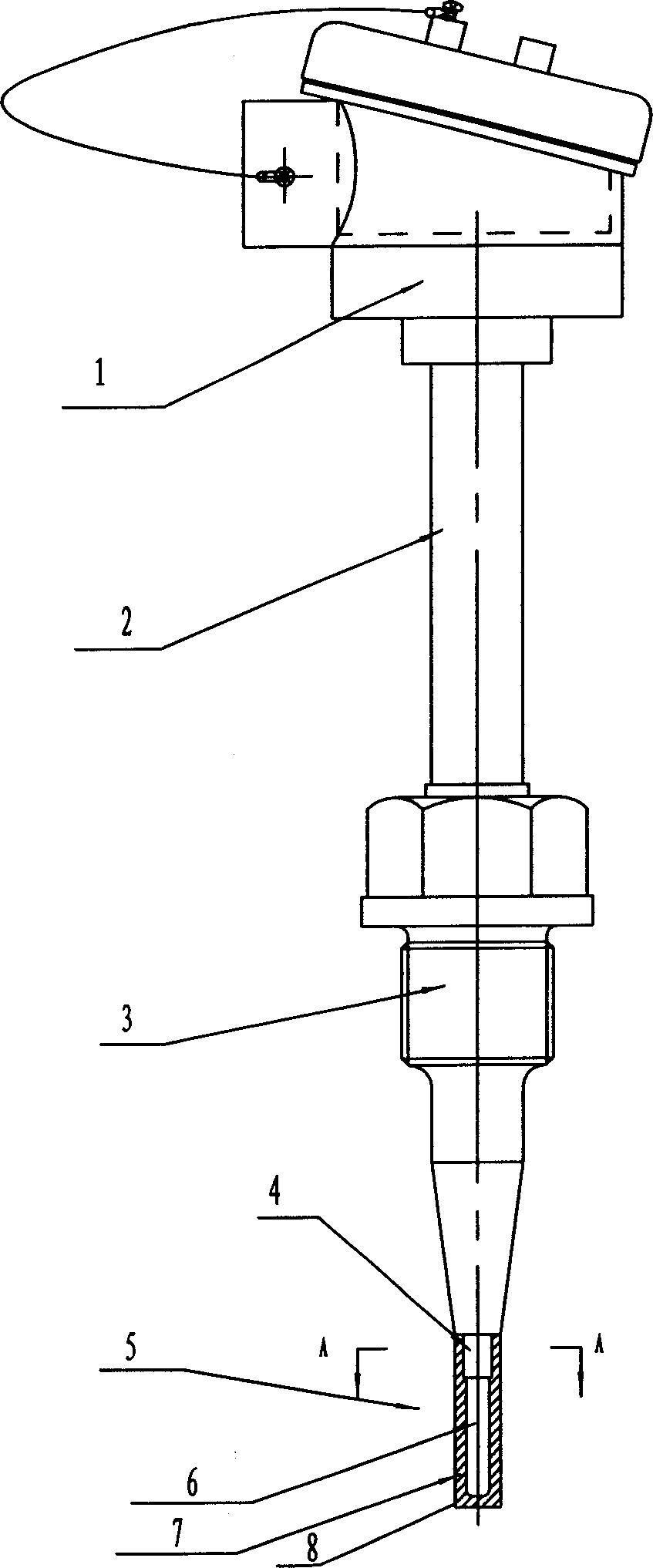

[0014] Such as figure 1 As shown, a small inert IE grade platinum resistance thermometer, which includes a stainless steel junction box 1, a protective tube 2, a fixing bolt 3, an armored platinum resistance body 4, a measuring terminal 5, a platinum resistance thermometer 6, a fixing bolt 3 and an outer protective sleeve 2 Welding, the metal 7 with good thermal conductivity is filled between the platinum resistance 6 in the measuring end 5 and the outer casing 8 of the measuring end.

[0015] The above-mentioned metal 7 having good thermal conductivity is silver-copper alloy or the like.

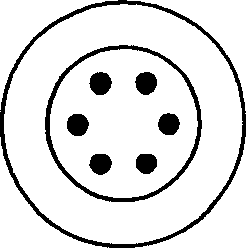

[0016] The above-mentioned armored platinum resistance body 4 is a double-core three-wire, such as figure 2 As shown, the diameter is Φ4.5mm~Φ5mm, and the length is determined according to the installation occasion.

[0017] The above junction box 1 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com