Silver halide color photographic light-sensitive material and color image-forming method

A color image and photosensitive material technology, applied in the direction of photosensitive materials, photosensitive material applications, multi-color photography technology, etc., can solve the problem of not describing the changes in the photographic properties of photosensitive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0989] (Preparation of blue sensitive layer emulsion BH-11)

[0990] Using a method of adding silver nitrate and sodium chloride to deionized distilled water containing deionized gelatin while stirring to mix them, cubic high silver chloride particles were prepared. In the preparation process, Cs is added in the step of adding 60% to 80% of the total amount of silver nitrate 2 [OsCl 5 (NO)]. Add potassium bromide (1.5 mol% per mole of final silver halide) and K in the step of adding 80% to 90% of the total amount of silver nitrate 4 [Fe(CN) 6 ]. K is added in the step of adding 83% to 88% of the total amount of silver nitrate 2 [IrCl 6 ]. Add K in the step of adding 92% to 98% of the total amount of silver nitrate 2 [IrCl 5 (H 2 O)] and K[IrCl 4 (H 2 O) 2 ]. When the total amount of silver nitrate added was 94%, potassium iodide (0.27 mol% per mol of final silver halide) was added under vigorous stirring. The emulsion particles thus obtained are monodisperse cubic silver iodobromo...

Embodiment 1-2

[1177] Flush B

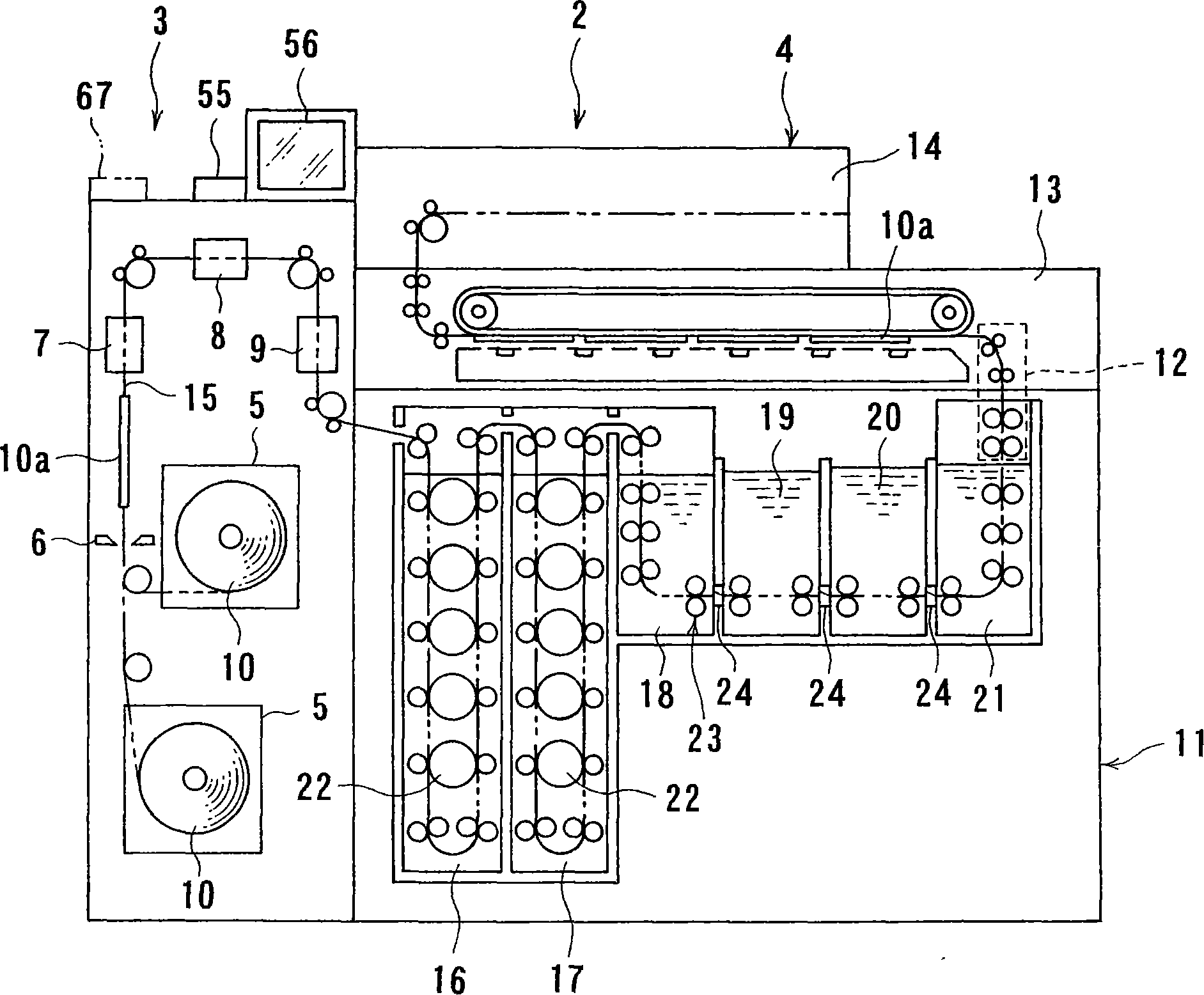

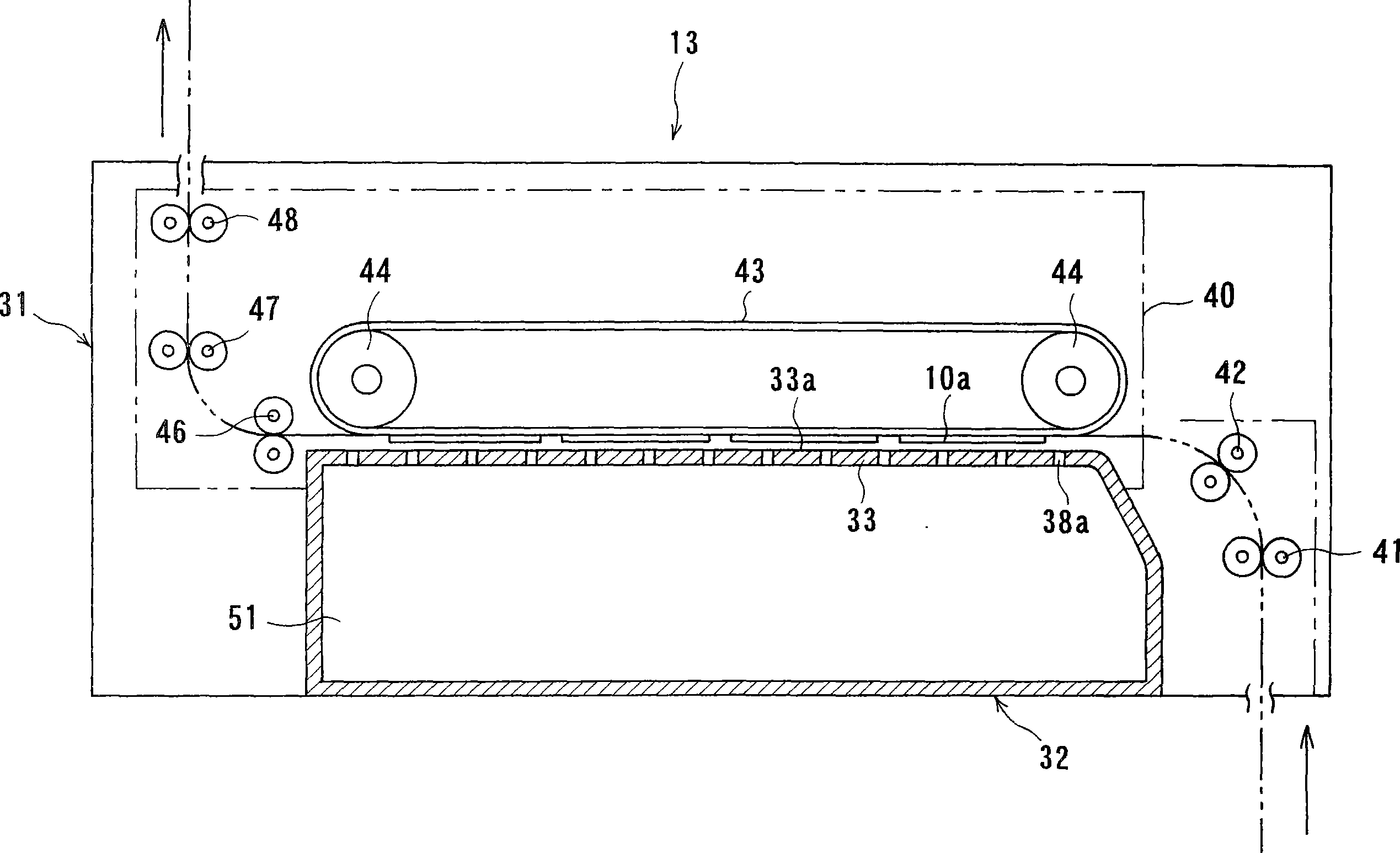

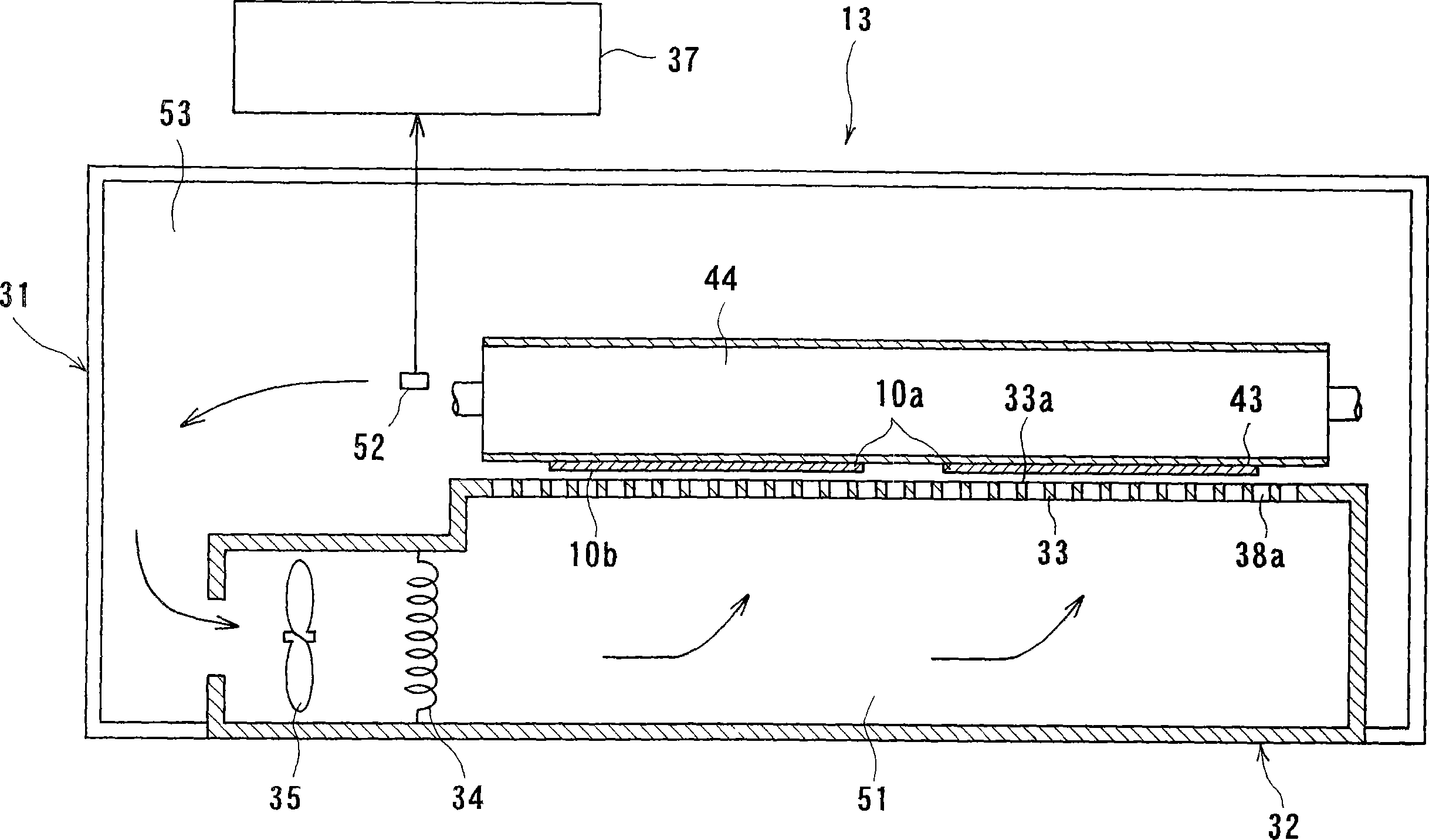

[1178] Each of the samples 1100 and 1105 in Example 1-1 was made into a roll with a width of 127 mm; Minilab Printer Processor Frontier 340 (trade name, manufactured by FujiPhoto Film Co., Ltd.; where the sheet conveying speed was set to 28 mm / sec ), expose the obtained sample with a standard photographic image; then continuously wash the exposed samples in the following washing steps (run test) until the cumulative amount of replenishing liquid of the color developer reaches twice the volume of the color developer tank .

[1179] Rinse step

[1180] Flush C

[1181] Rinse step

[1182] After coating, a set of samples of samples 1100 and 1105 were stored at 25°C-55%RH for 5 days, and then stored in a frozen state at -5°C. After coating, another set of samples of samples 1100 and 1105 were stored at 25°C-55%RH for 8 days, and then stored in a frozen state at -5°C. After coating, another set of samples of samples 1100 and 1105 were stored at 25°C...

Embodiment 1-3

[1196] The following sample 1301 and sample 1302 were prepared. Rinse these samples according to Rinse A as described in Example 1-1. As a result of evaluation according to Example 1-1, it is shown that these samples can achieve effects similar to those prepared in Example 1-1 according to the present invention.

[1197] -Preparation of sample 1301-

[1198] The sample 1301 was prepared in the same manner as the sample 1105 except that the composition of the third layer and the fifth layer was changed as described below.

[1199] The third layer (green sensitive emulsion layer)

[1200] Emulsion (1∶3 mixture of GH-11 and GL-11 (molar ratio of silver)) 0.12

[1201] Gelatin 0.95

[1202] Magenta coupler (Ma-48) 0.21

[1203] Oleyl alcohol 0.33

[1204] Color image stabilizer (ST-1) 0.04

[1205] Color image stabilizer (ST-2) 0.28

[1206] The fifth layer (red sensitive emulsion layer)

[1207] Emulsion (4:6 mixture of RH-11 and RL-11 (molar ratio of silver)) 0.15

[1208] Gelatin 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

| Side length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com