Plasma display panel and its manufacture method

A technology for a display panel and a manufacturing method, applied in the direction of alternating current plasma display panels, cold cathode manufacturing, electrode system manufacturing, etc., capable of solving the problems of deterioration of discharge characteristics and high driving voltage of plasma display panels, and achieving lower discharge voltage and stable discharge characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments are given, and detailed descriptions are given in conjunction with the accompanying drawings.

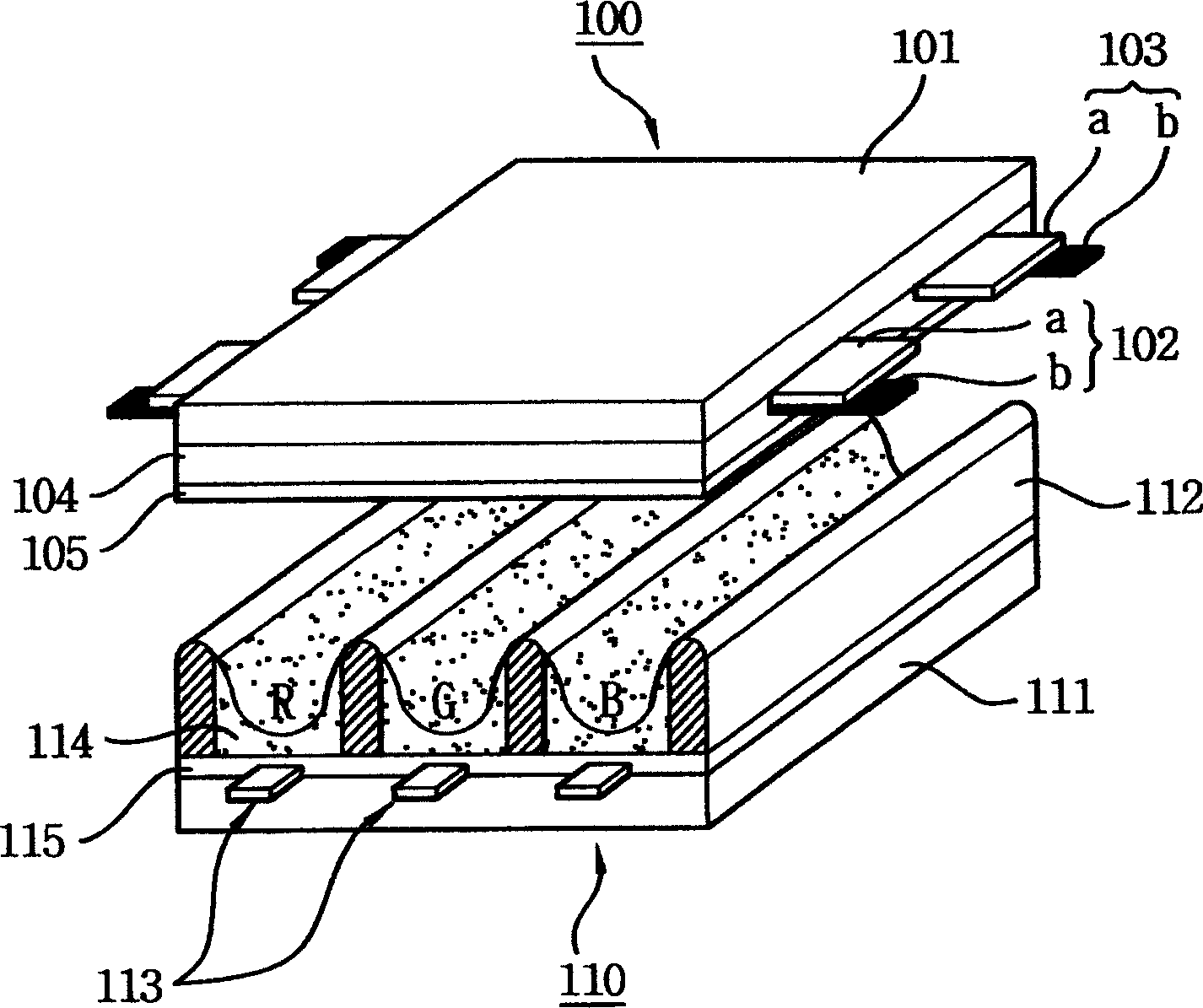

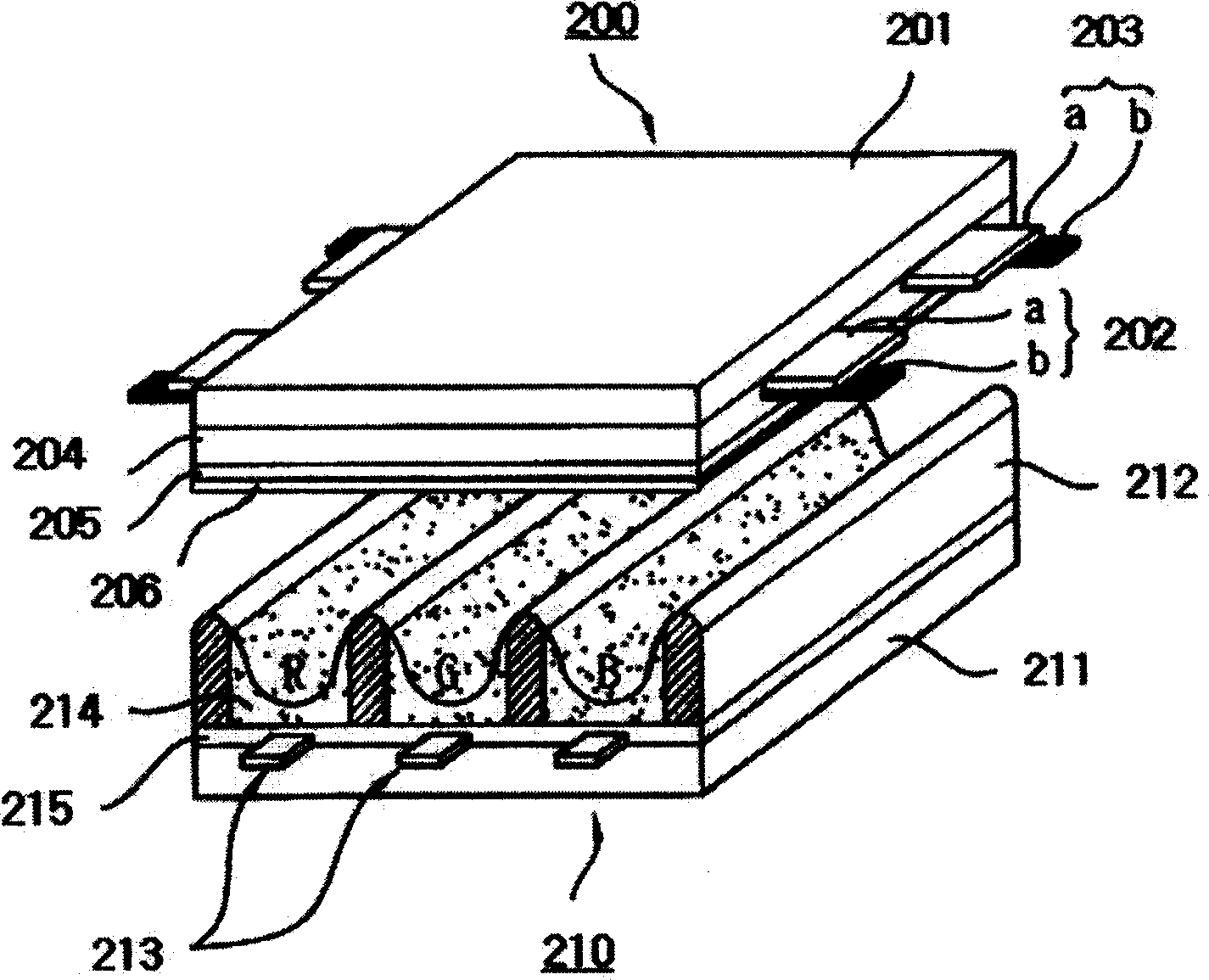

[0043] figure 2 It is a schematic diagram of the structure of the plasma display panel in the first embodiment of the present invention. Such as figure 2 As shown, the plasma display panel in the first embodiment of the present invention is composed of a front substrate 200 and a rear substrate 210 .

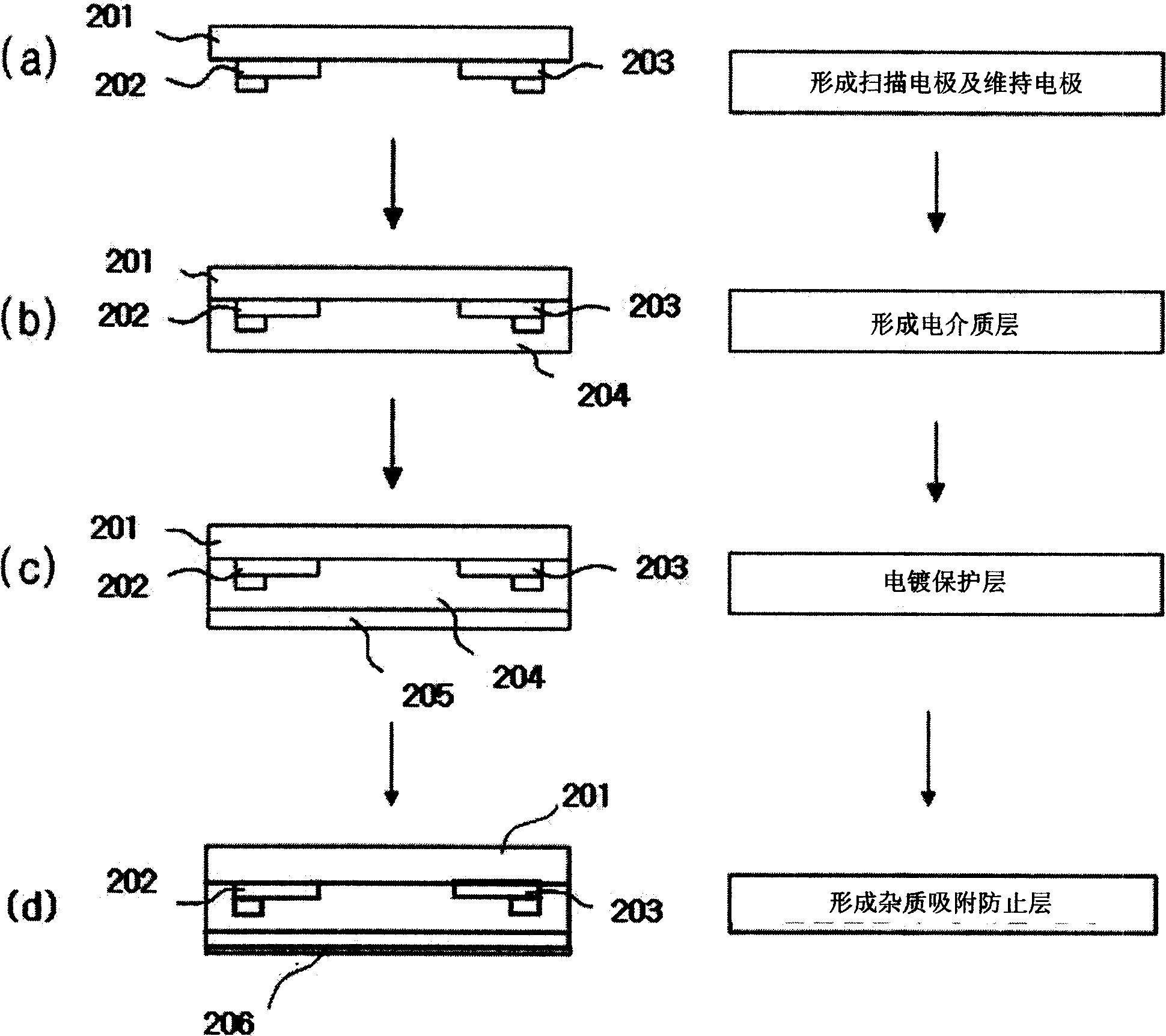

[0044] The front substrate 200 discharges each other in a discharge cell (cell), and the sustain electrode 202 and the scan electrode 203 that sustain the cell (cell) emit light, that is, the transparent electrode (a) and the transparent electrode (a) formed of a transparent ITO (Indium Thin Oxide) material. Sustain electrodes 202 and scan electrodes 203 composed of bus electrodes (b) made of metal materials are covered with one or more dielectric layers 104 that limit discharge current and insulate electrode pairs. On the dielectric laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com