Exhaust gas catalyst

A technology of catalysts and hydroxides, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problems of developing stable catalysts without durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

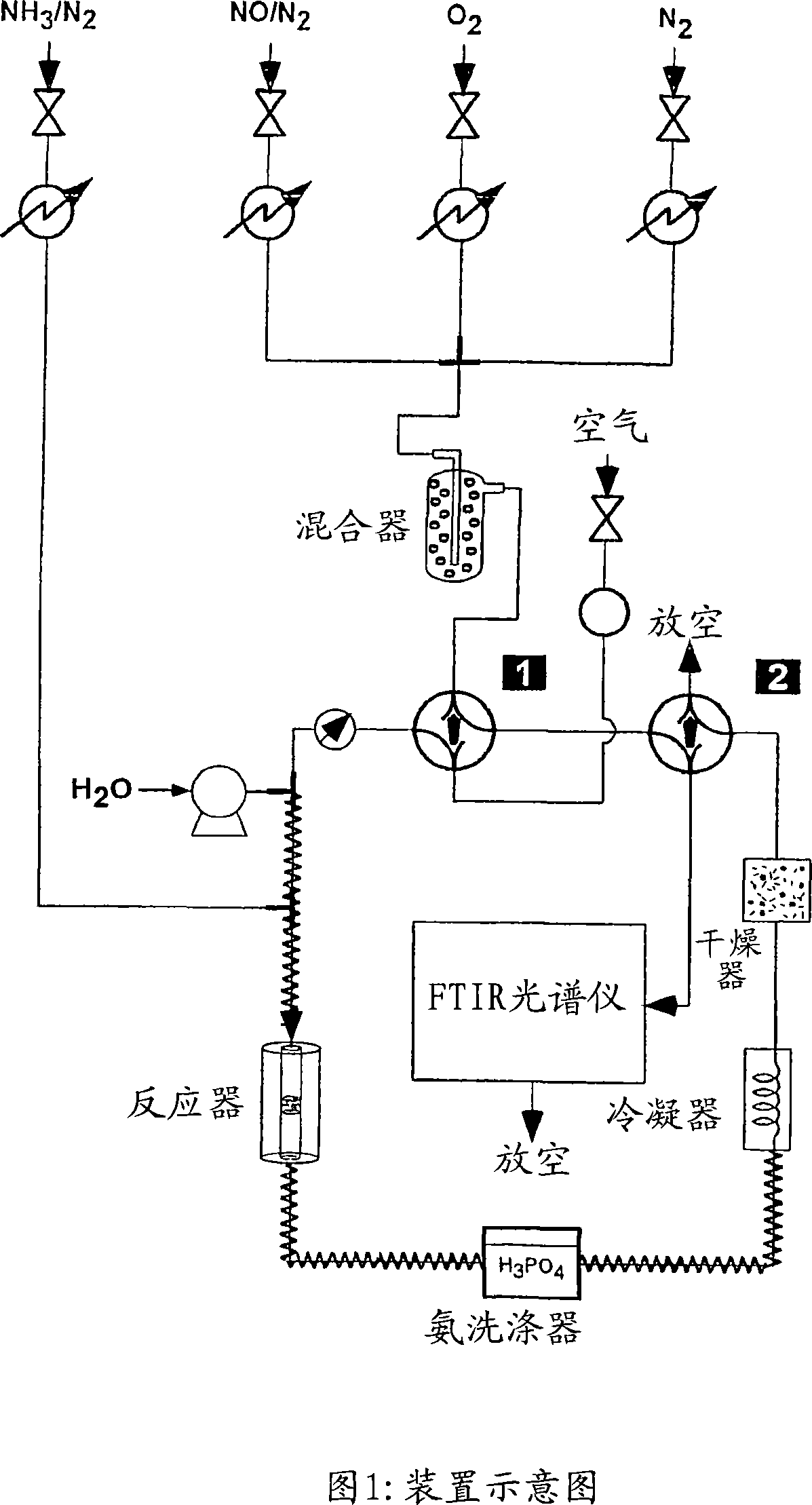

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in more detail in the following preferred embodiments.

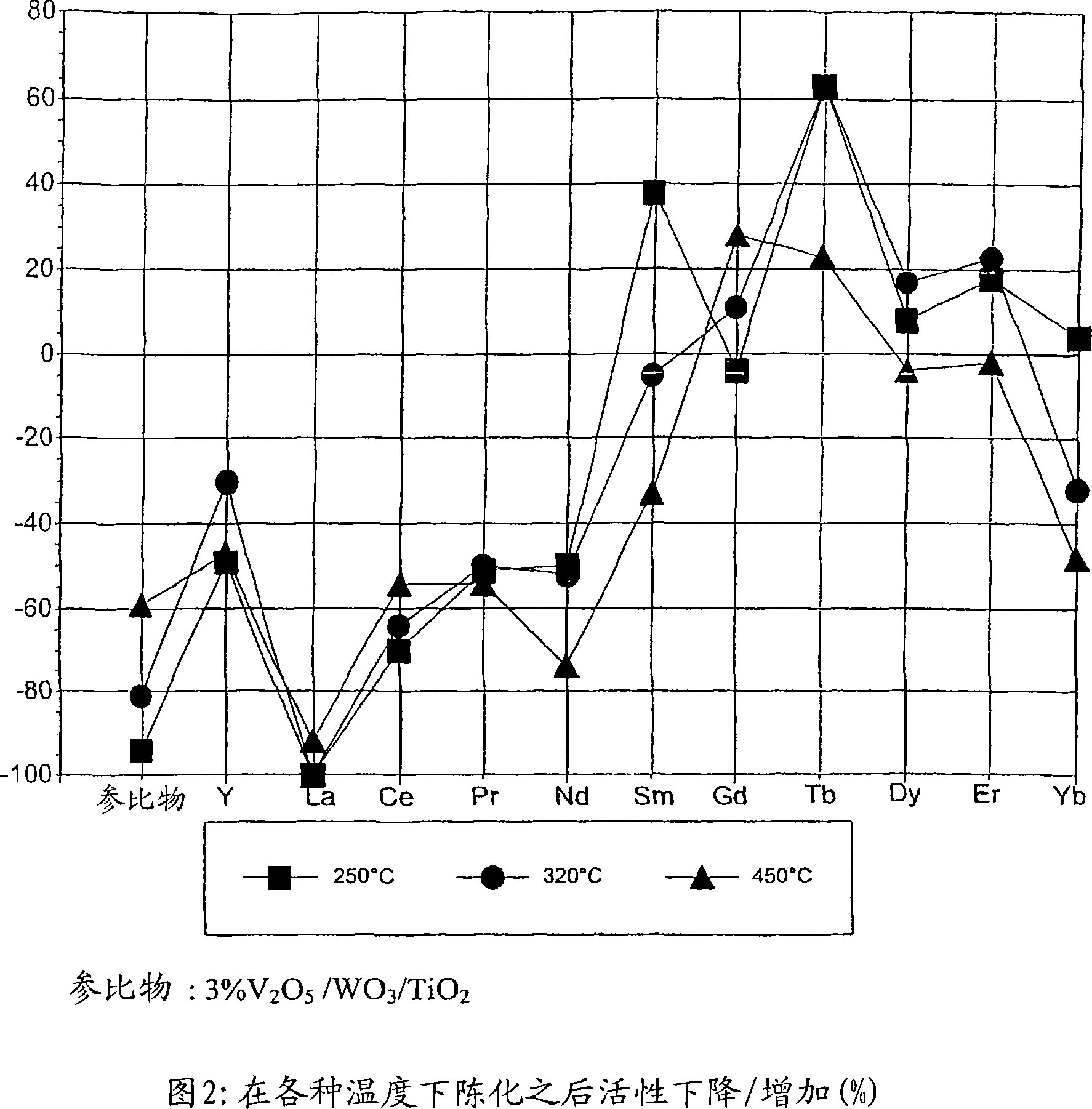

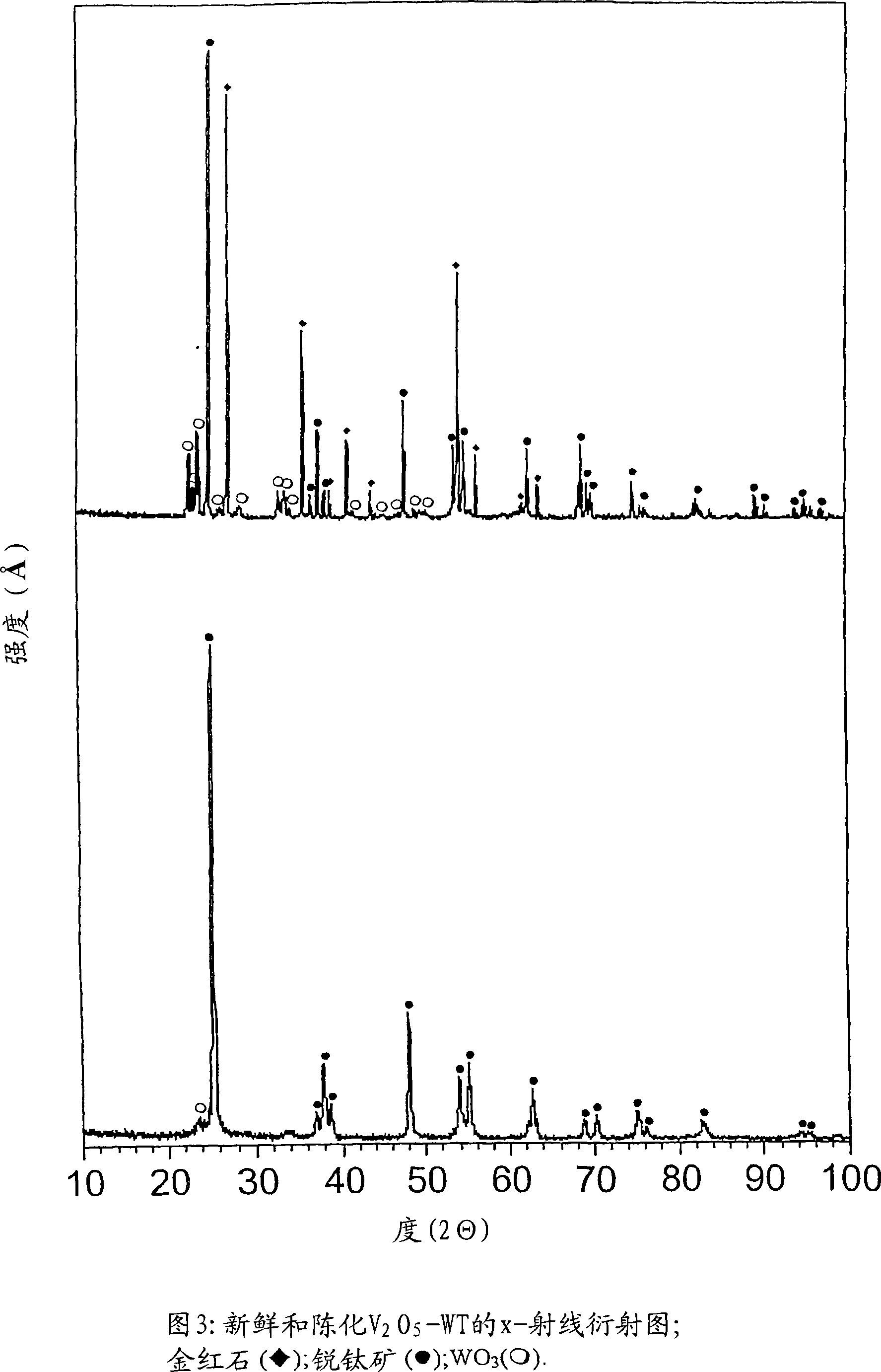

[0038] The catalyst according to the invention is obtained starting from the following two support materials, namely the composition 81% TiO 2 -9% WO 3 -10% SiO2 2 (Ti / W / Si) and composition 90% TiO 2 -10% WO 3 (Ti / W). A combination of V and RE elements is added to this support to provide NO represented by the general formula REVO / Ti-W-Si x Reduction catalysts where RE=Y, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Er and Yb. The content range of the active phase is at most 5.1wt% RE element, 0.4-2.1wt% vanadium and at most 2.7wt% oxygen, which is equivalent to 2.5-8.5wt% REVO dosage.

[0039] 1. According to the preparation of the catalyst of the present invention, containing 5.0wt% Er and 1.5wt% V, loaded on the Ti-W-Si carrier

[0040] 1.1 Preparation of Ti-W-Si support

[0041] Carrier preparation is carried out according to (7): 92.68g titanium tetrachloride (TiCl 4 ) was added drop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com