Applying device

A technology of coating device and coating liquid, which is applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of increasing work load, difficulty in ensuring the quantification of coating amount, etc., and achieves reduction of vibration and Undulating, easily adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be described below based on the drawings.

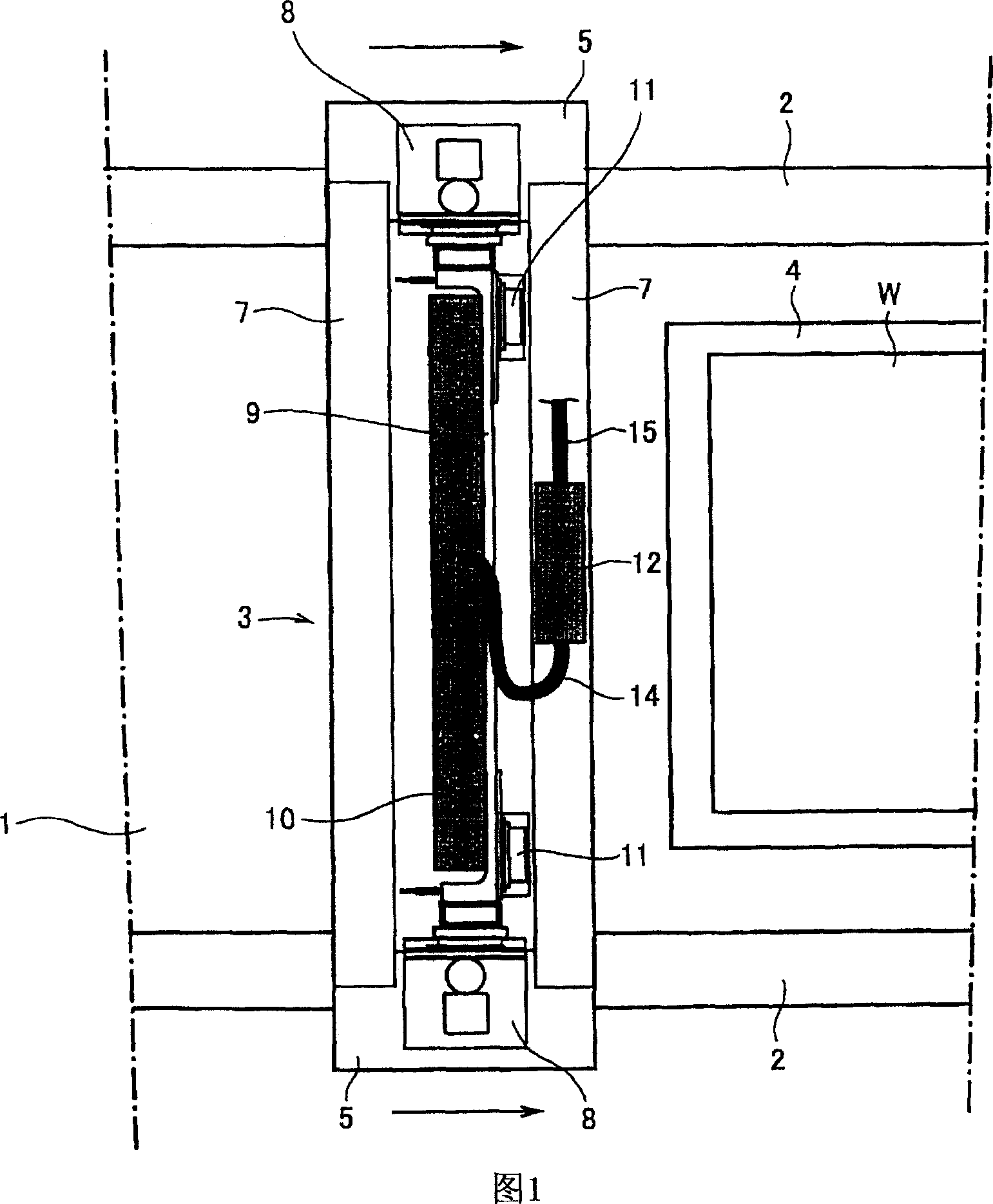

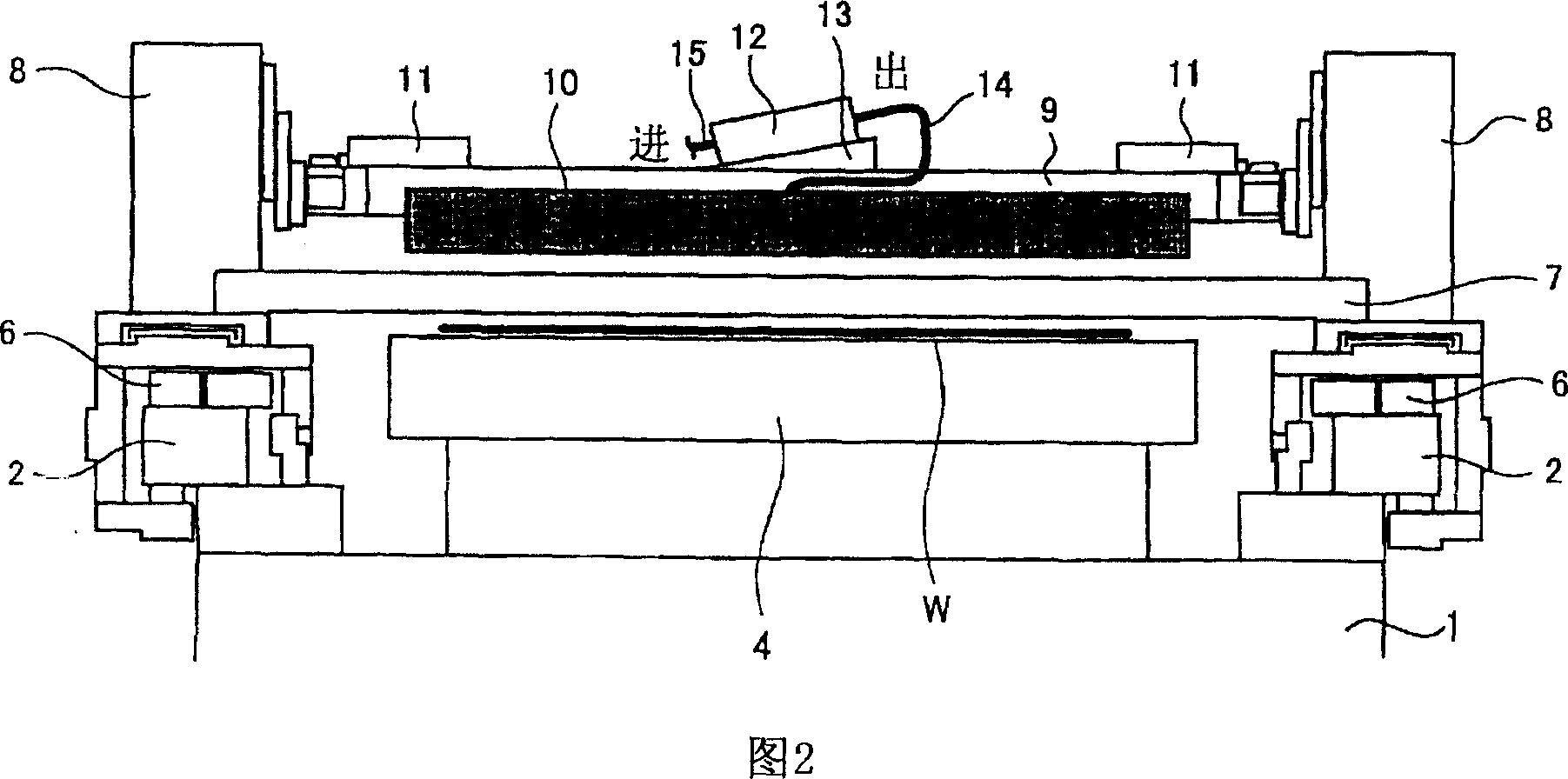

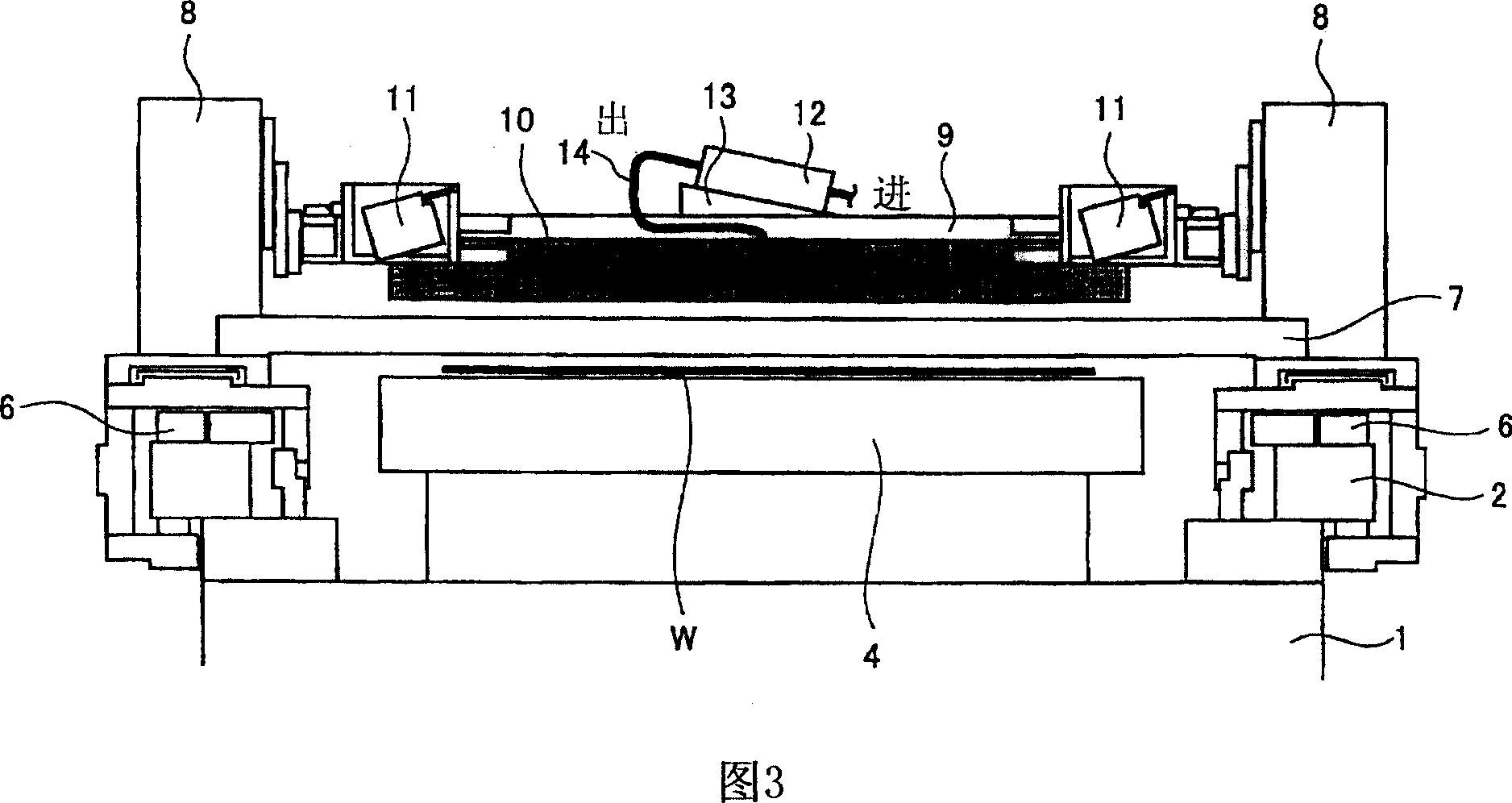

[0045] FIG. 1 is an enlarged plan view showing part of a coating device according to an embodiment of the present invention. In addition, FIG. 2 is a view in the direction of A in FIG. 1 , FIG. 3 is a view in the direction of B in FIG. 1 , and FIG. 4 is an enlarged side view for explaining the mounting state of the slit nozzle.

[0046] As shown in FIGS. 1 to 3 , the coating device according to this embodiment is supported by a base 1 .

[0047] On the base 1, a pair of rails 2, 2 are provided in parallel in the horizontal direction, and a door-shaped moving mechanism 3 is engaged with the pair of rails 2, and on the base 1, a platform for placing a glass substrate W and the like is provided. The substrate mounting platform 4 .

[0048] The gate-shaped moving mechanism 3 has a gantry frame 5 as a moving body in a shape surrounding the rail 2 , and an air cushion 6 forming a gap with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com