Process equipment for integral ring-shaped finned tube and technique thereof

A technology for processing equipment and finned tubes, which is applied in the field of processing equipment for integral annular finned tubes, can solve the problems of not well eliminating gaps, hindering heat exchange and short service life, and improving heat conduction efficiency and product quality. The effect of increasing and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

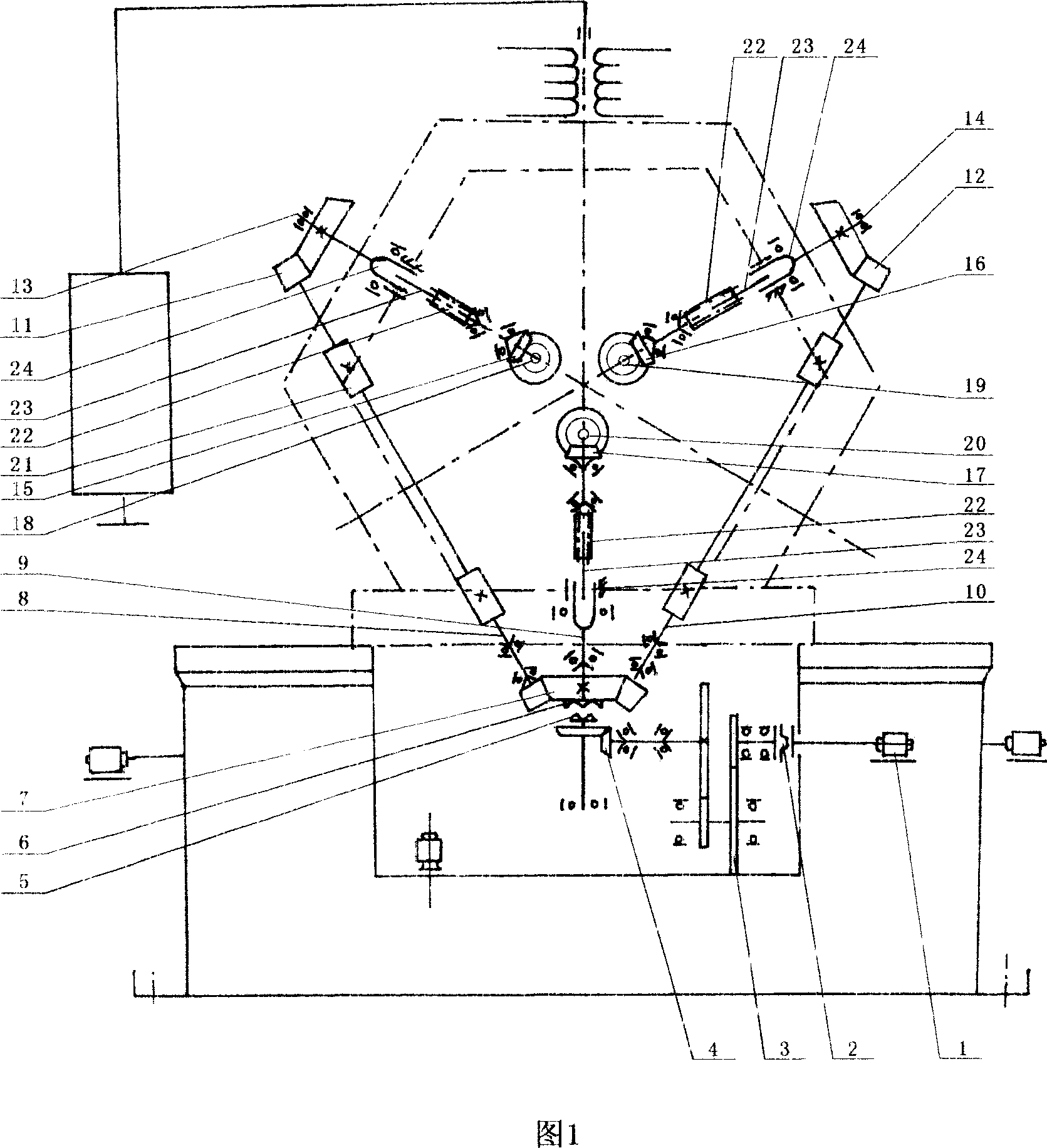

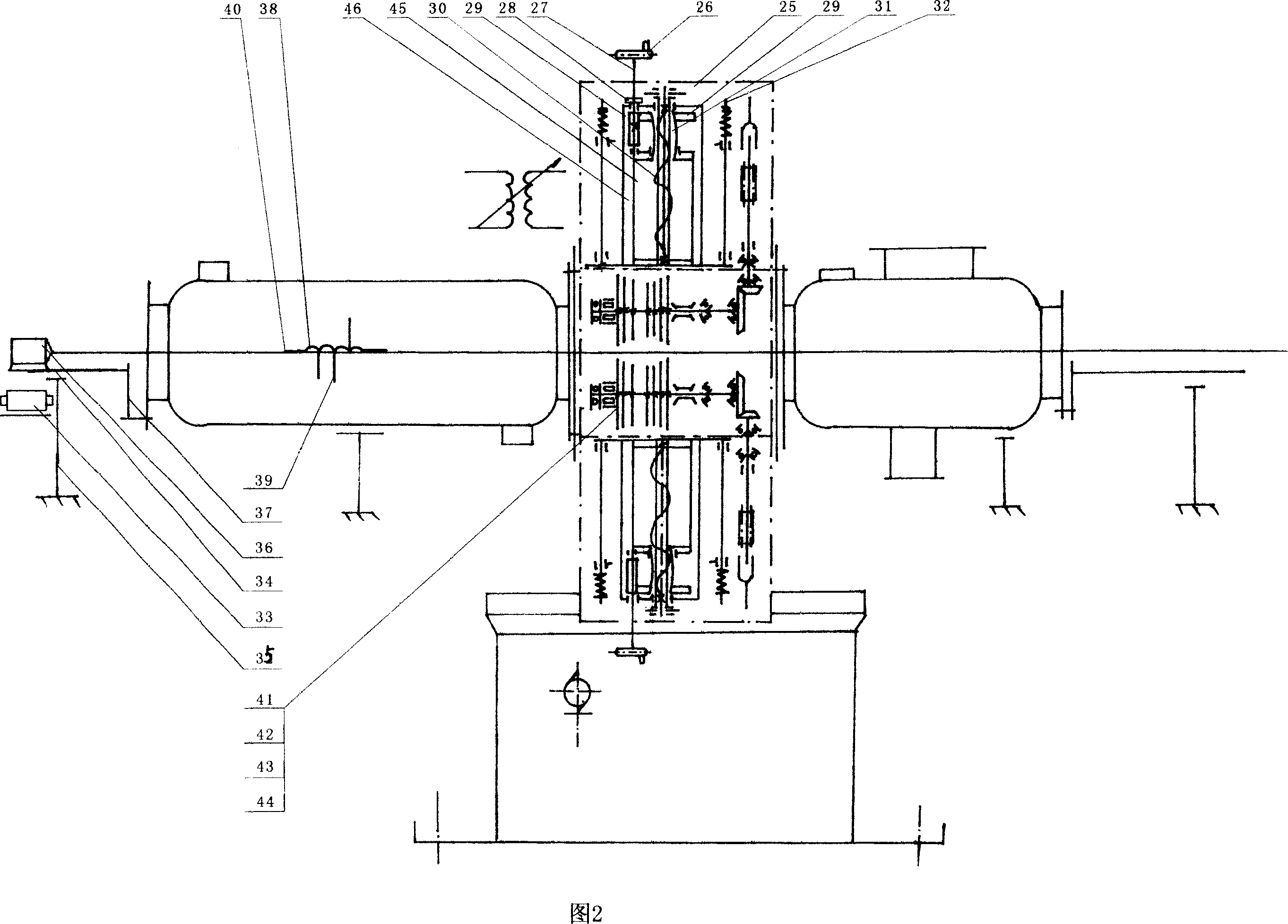

[0029]As shown in Figures 1 and 2, the processing equipment for the overall annular finned tube, its multi-station mutual control finned tube rolling device, is mainly driven by the drive motor 1 through the coupling 2 to transmit the power to the reduction mechanism 3 , the power output shaft of the reduction mechanism is connected with the gear pair 4, and the output shaft of the gear pair 4 is connected with a clutch 5, and a compound bevel gear 7 is fixedly installed on the other end of the clutch 6 shaft; the left, middle and right three of the compound bevel gear 7 The two bevel gears are installed on the transmission shafts 8, 9, 10 respectively, wherein the other ends of the left and right two bevel gear transmission shafts 8, 10 are respectively fixedly connected to the gear pairs 11, 12, and the low-level bevel gears of the two gear pairs are installed on the transmission shafts respectively. On shaft 13,14, power transmission shaft 13,14 respectively connects other t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com