Full-automatic hot blast stove

A hot blast stove, fully automatic technology, used in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of cumbersome operation, high temperature, insufficient precision, etc., to ensure smooth operation, increase heat dissipation area, improve The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

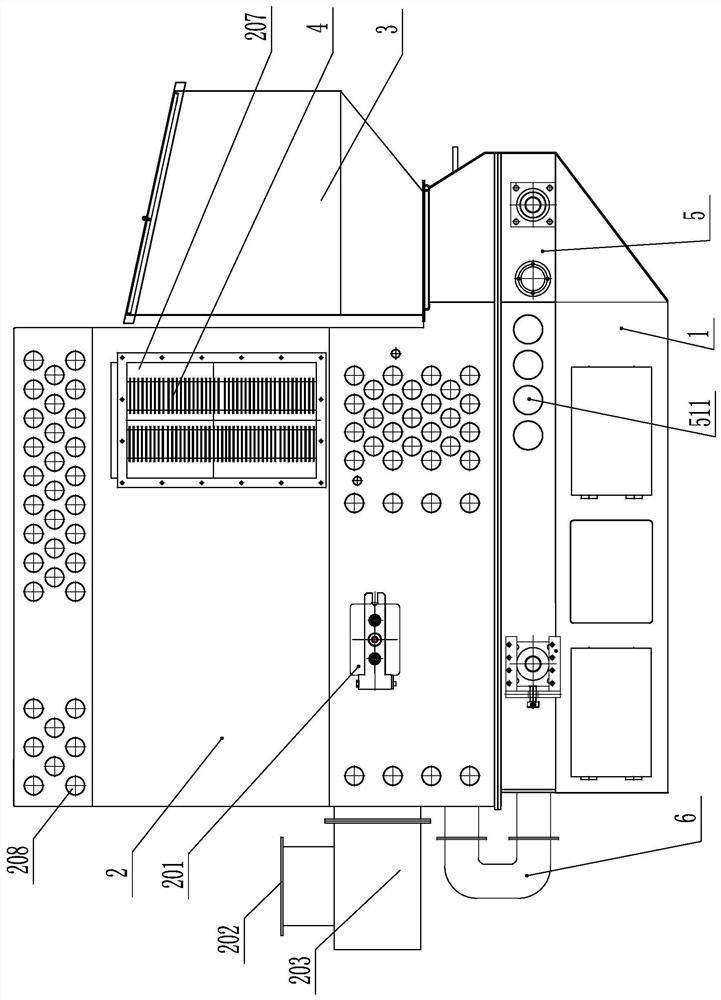

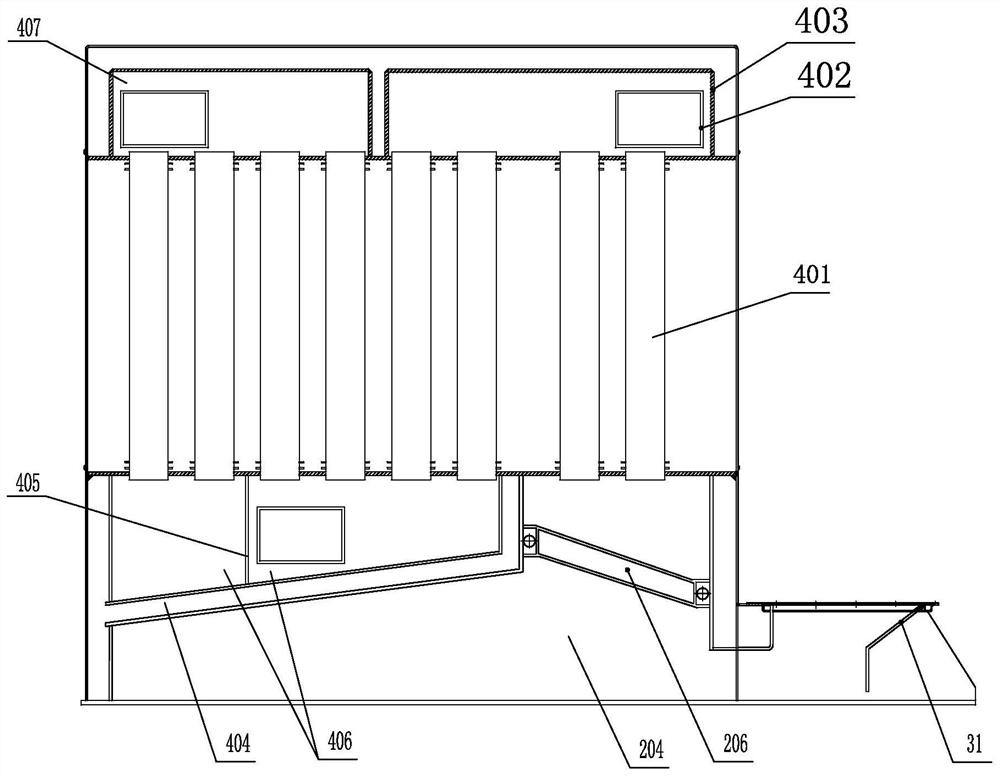

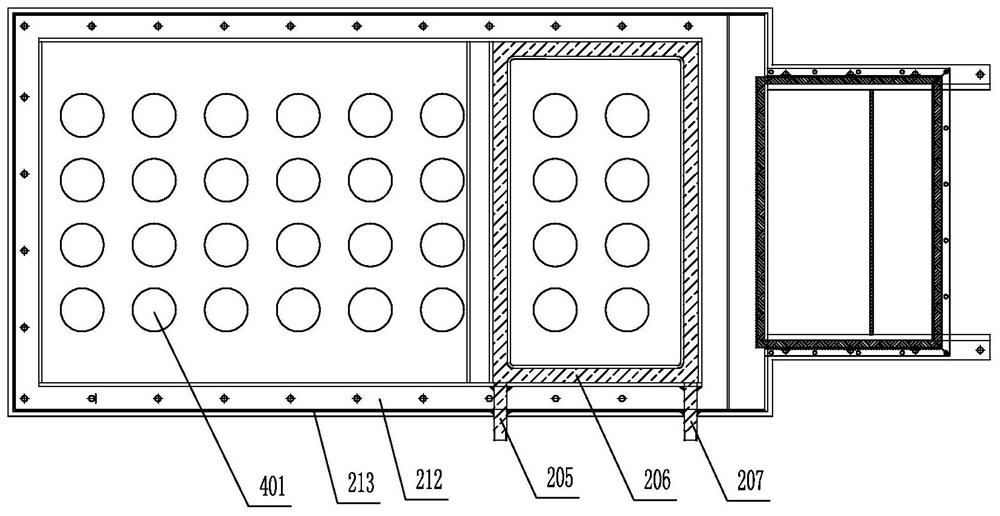

[0043] Embodiment 1: as figure 1 , figure 2 , Figure 6 Shown, the present invention comprises base 1, furnace body 2, material storage bin 3, fire grate seat 5, air blower, single-chip microcomputer, feeding device 8, temperature sensor 9 and combustion chamber 204, heat exchanger 4 in body of furnace 2, so The furnace body 2 is placed on the base 1 through the grate seat 5, the feeding device 8 is placed in the grate seat 5, the heat exchanger 4 is above the combustion chamber 204 in the furnace body 2, and the furnace body 2 is close to the storage bin 3 and corresponds to One side of the heat exchanger 4 has a hot air outlet 211, and the corresponding other side is connected with a blower, such as figure 2 , image 3As shown, the heat exchanger 4 communicates with the combustion chamber 204 and is separated by a first partition 404, including multiple sets of hot air pipes 401 arranged side by side vertically, a deflector 403 and a dust settling chamber 406. Above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com