Nano super composite fertilizer and preparation process for the same

A manufacturing method and technology of compound fertilizer, which are applied in magnesium fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of small improvement in formula and insignificant fertilizer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0055] [Preparation Example 1] Production of Nano Super Compound Fertilizer Component (A1).

[0056] main ingredient

[0057] A: (A) nanomaterials (more than 90% of nanomaterials) 9.97

[0058] (B) 2-Chloroethyltrimethylammonium chloride and potassium alum 0.03

[0059] B: seawater fine fertilizer (MgO content 95%) 200

[0060] C: Ammonium sulfate (25% N content) 600

[0061] D: H 2 PO 4 (P content 85%) 80

[0062] E:K 2 O (including K 2 O60%) 100

[0063] F: B, Se, Si, Mn, Zn, Mo trace elements, naphthalene acetic acid, red enzyme element 10

[0064] Operation method:

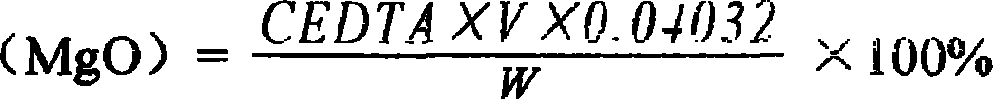

[0065] First, dissolve the pulverized nanomaterials in 6 times of water, stir for 20 minutes, filter out the water-insoluble matter, add 0.03 2-chloroethyltrimethylammonium chloride and potassium alum and stir for 30 minutes, when the components reach At a certain Baume degree, add seawater fine fertilizer (MgO) and metathesis oxide, stir for 15-25 minutes, let it stand for 10 minutes, release the l...

preparation example 2

[0069] [Preparation example 2] the manufacture of nano super compound fertilizer component (A2):

[0070] The ammonium sulfate in Preparation Example 1 was replaced with ammonium nitrate with a nitrogen content of 36%, and the rest of the conditions were kept unchanged. The mixture was reacted and stirred at 30-78° C. for 120 minutes to obtain a paste-emulsion mixture (A2) with a conversion rate of 96%.

[0071] The manufacturing process refers to the method of the nano super compound fertilizer component (A1), and the method provided by (A1) is used to obtain the component of (A2). The content of (A2) except N increased to 21.6% (analyzed by general chemical separation method), the total nutrient content increased to about 63%, and the others remained unchanged.

manufacture example 3

[0072] [manufacturing example 3] the preparation of nanometer super compound fertilizer (A3):

[0073] The nitrogen fertilizer in the preparation example 1 is changed into ammonium chloride (content 25%), other conditions are constant, and total nutrient composition is identical with (A1) example gained composition, but the fertilizer containing chlorine root component, in some avoiding chlorine root crops cannot be used on .

[0074] [Preparation of A4 example] the manufacture of nano super compound fertilizer (A4), change (A1) nitrogen fertilizer into ammonium phosphate (comprising monoammonium phosphate and diammonium phosphate, N content 18%, P content is 45%) its N content Decline to 10.8%, its P content rises to 33.8%, and the total nutrient content reaches more than 80%.

[0075] [Preparation of A5 example] the component (A5) of nanometer super compound fertilizer, change (A1) nitrogen fertilizer into urea (content 46%), H 2 PO 4 With other conditions unchanged, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com