Pile bottom mud jacking method for pump-grouting concrete and structure of madjack pipe

A technology of bored piles and grouting pipes, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of large amount of cleaning slurry, environmental pollution of the platform, and high cost, so as to improve the bearing capacity of foundation piles and reduce the Cost, material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

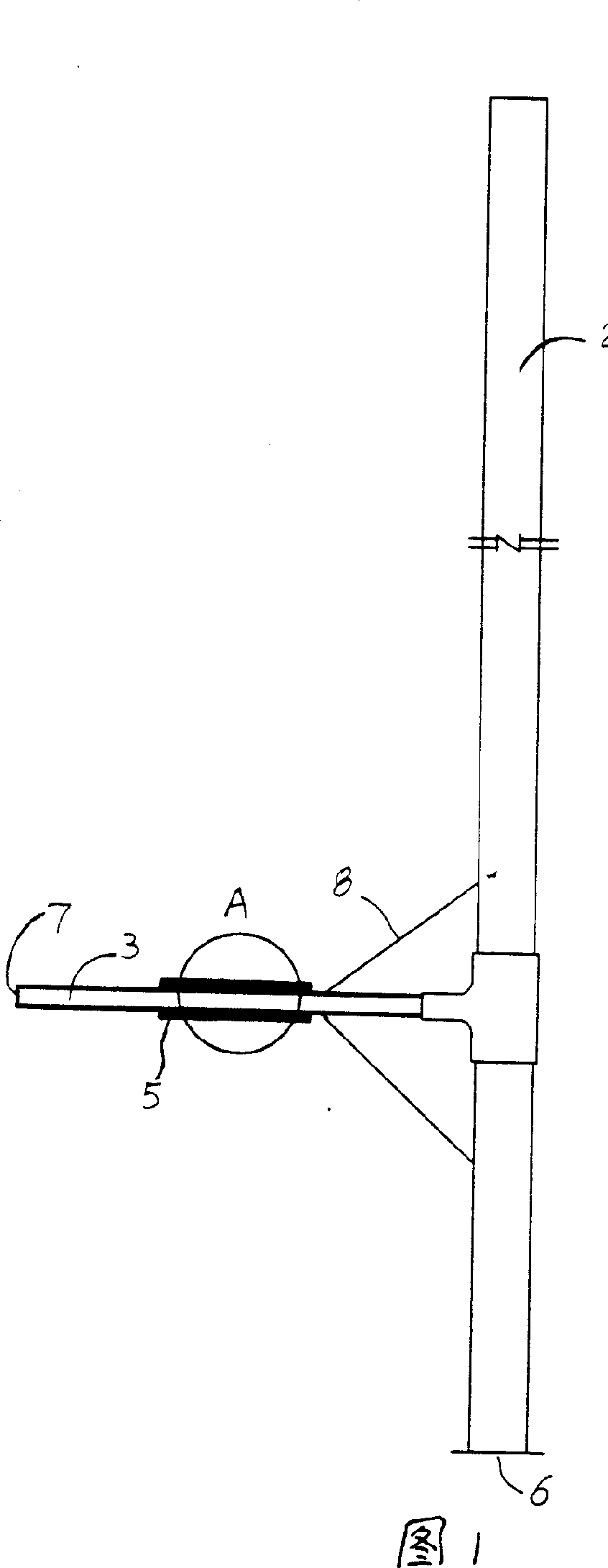

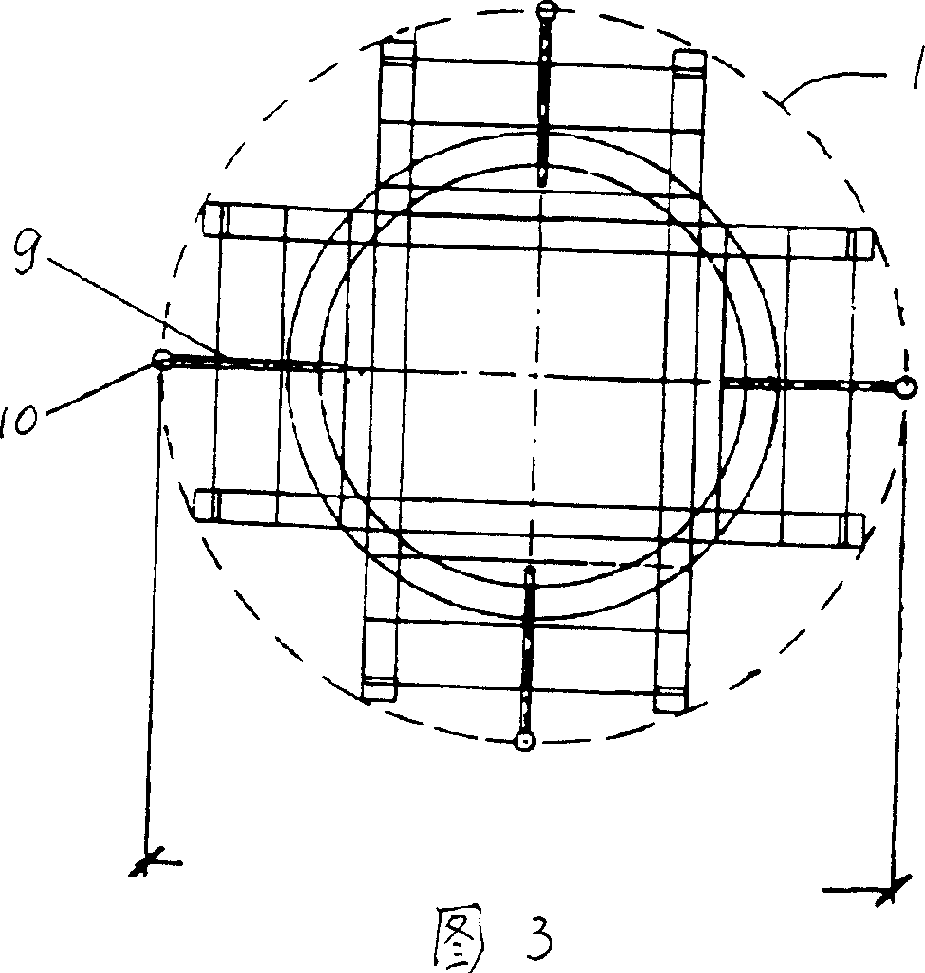

[0015] A method for grouting the bottom of a concrete bored pile. Four straight pipes 2 are evenly distributed and fixed on a reinforcement cage 1, and the lower part of the straight pipe is connected with an elbow 3 to form a grouting pipe 9. The grouting tube in this embodiment is replaced by an acoustic tube, that is, the acoustic tube 10 and the grouting tube 9 are the same tube.

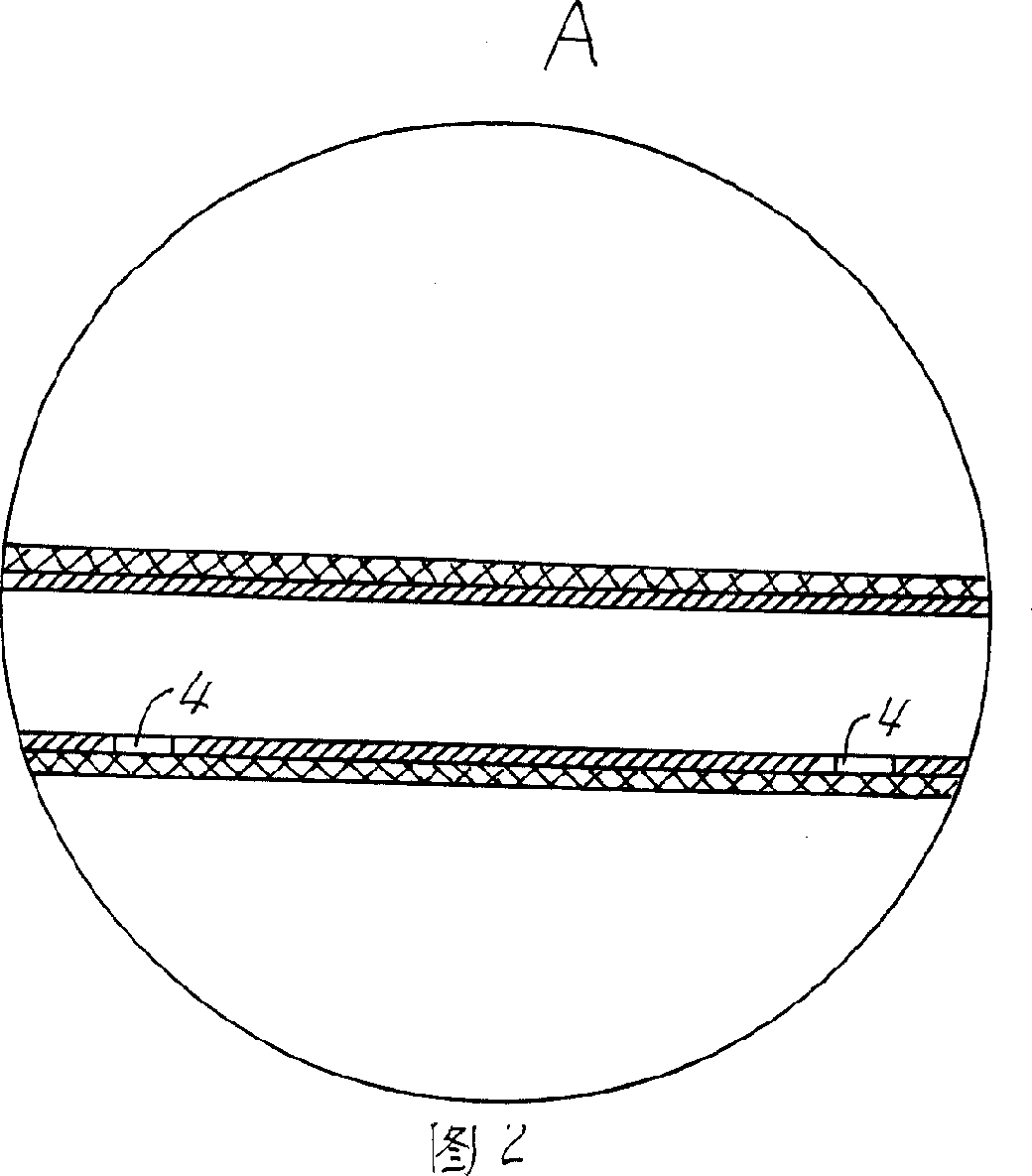

[0016] The bending direction of the elbow is towards the center of the pile, and there are two grouting holes 4 in the downward direction of the elbow, and the diameter of the grouting hole is 8mm; the outside of the grouting holes is wrapped with a rubber sleeve 5; To strengthen the strength of the bent pipe, the other ends of the four straight pipes can be fixed by the end-capping steel plate 6. In order to strengthen the strength of the bent pipe, a reinforcing plate 8 can be fixed at the connection between the straight pipe and the bent pipe; the upper end of the straight pipe is installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com