Process for preparing wet swelling granule material for soft-shelled turtle

A technology of extruded granules and production technology, which is applied in the shaping or processing of animal feed, application, animal feed, etc. It can solve the problems of digestion and absorption rate, low conversion utilization rate of feed, failure to popularize puffed granules for soft-shelled turtles, and insufficient use of additives. Reasonable and other issues to achieve the effect of reducing the occurrence of bacterial diseases, reducing the outbreak rate of bacterial diseases, and improving immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: This soft-shelled soft-shelled soft-shelled turtle is made of the following raw materials by weight ratio: white fish meal 40%, red fish meal 15%, soybean meal or other cakes of expanded soybean 15%, yeast 8 %, 19% flour, 0.2% gluten or other binders, 0.5% vitamin additives, 0.3% probiotics, 1.5% oil and 0.5% trace element additives. The specific composition of the probiotics is that the probiotics contain at least 5 billion Bacillus subtilis per gram of the probiotics.

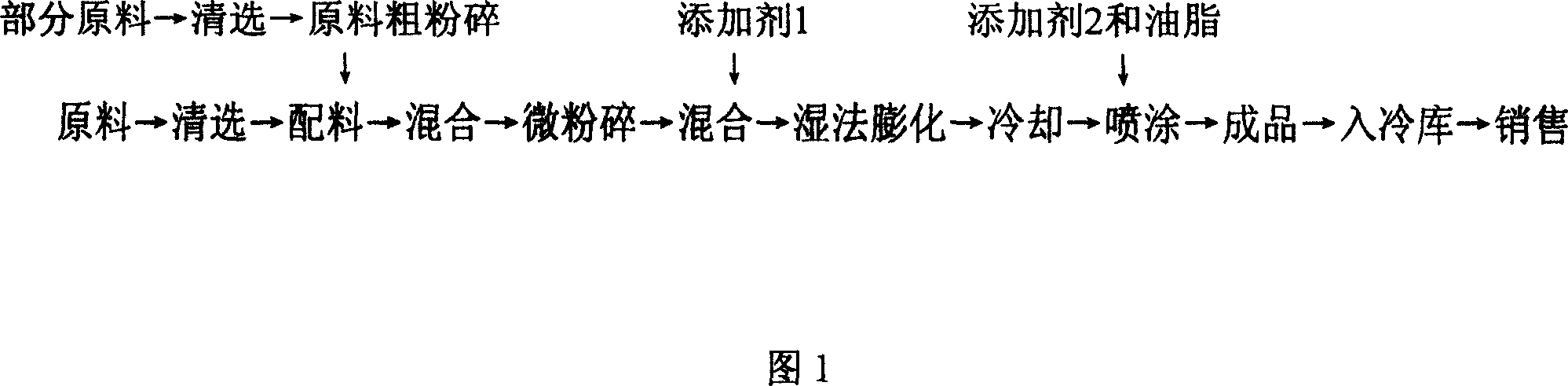

[0016] As shown in Figure 1, the production process of this soft-shelled soft-shelled soft-shelled turtle mainly includes the following steps:

[0017] 1) First, mix the required materials, 40% of white fish meal, 15% of red fish meal, 15% of soybean meal or other cakes of puffed soybean, 8% of yeast, 19% of flour, gluten or other binders 0.2%, 0.5% trace element additives, poured into the receiving tank according to the above weight ratio, through the elevator, the materials go through ...

Embodiment 2

[0022] Embodiment 2: The difference from Example 1 is that this soft-shelled soft-shelled turtle uses wet puffed pellets, which are made of the following raw materials in weight ratio: white fish meal 58%, red fish meal 5%, soybean meal or puffed 5% other soybean cakes, 3% yeast, 19% flour, 2.0% gluten or other adhesives, 1.5% vitamin additives, 1.0% probiotics, 3.5% added oil, and 2 trace element additives %. The specific composition of the probiotics is that the probiotics contain at least 5 billion Bacillus subtilis per gram of the probiotics.

Embodiment 3

[0023] Embodiment 3: The difference from Example 1 is that this soft-shelled soft-shelled turtle uses wet puffed pellets, which are made of the following raw materials in weight ratio: 50% white fish meal, 10% red fish meal, soybean meal or puffed 10% of soybean cakes, 5% of yeast, 19% of flour, 1% of gluten or other adhesives, 1% of vitamin additives, 1.0% of probiotics, 2% of oil, and 1% of trace element additives %, wherein the specific composition of the probiotics contains at least 5 billion Bacillus subtilis per gram of the probiotics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com