On-line detection apparatus for anode current distribution

A detection device and anode current technology, which is applied in the field of online continuous detection devices to achieve the effects of stabilizing cell conditions, optimizing process parameters and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

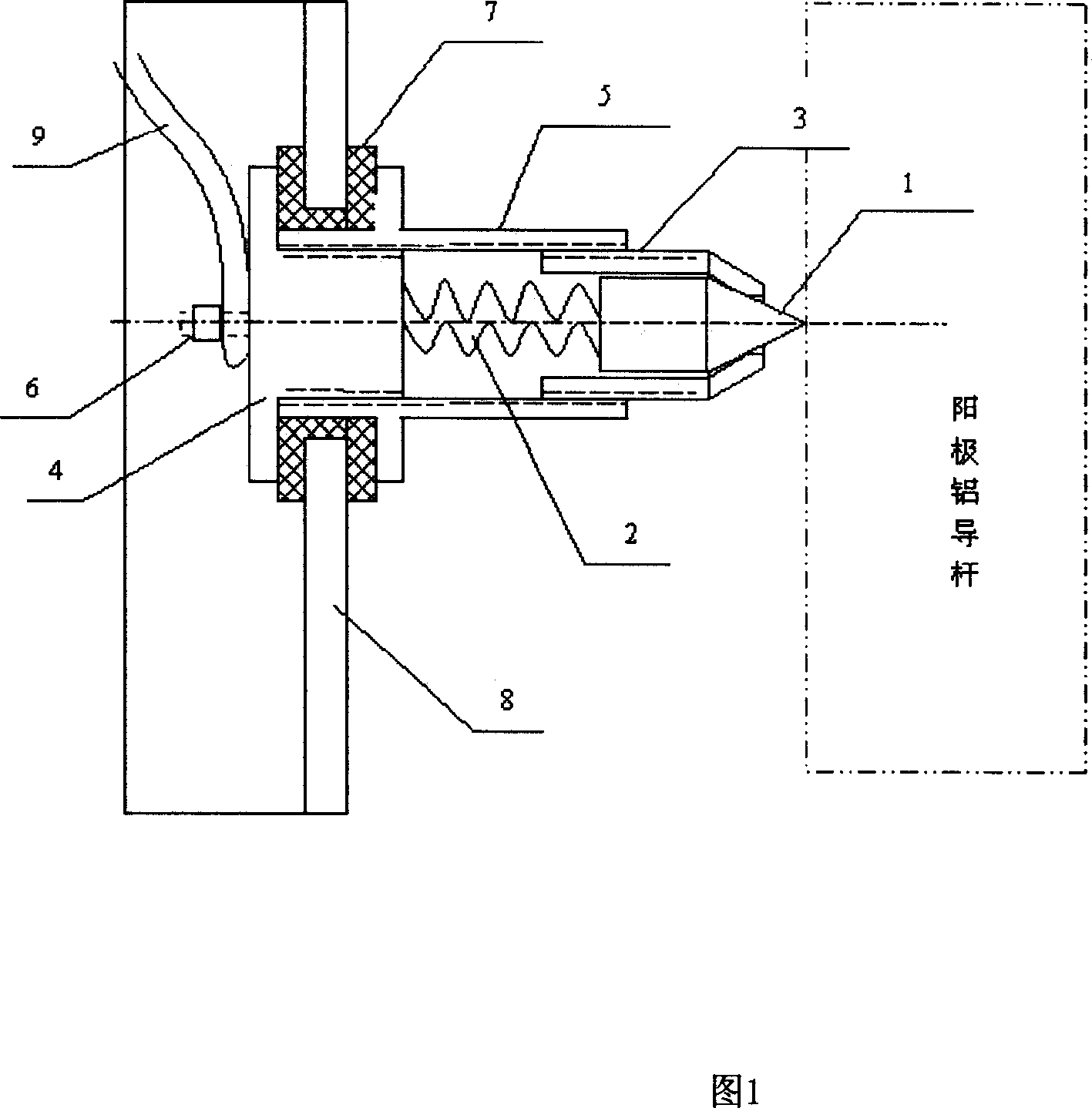

[0013] In practical applications, a set of testing equipment is generally composed of two sets of measuring devices, so that the equidistant pressure drop signal of the anode guide rod can be measured. The installation distance of the two sets of measuring devices is determined according to the actual process and the installation position on the tank. It can be installed on the anodized aluminum bus bar or the support of the small joint fixture. The measuring wires (high temperature resistance) can be connected to the input terminal of the slot control machine in groups through the cable protection sleeve for signal transmission and data processing.

[0014] The conical contact (1) of the present invention is a signal detection element, which is mainly responsible for contacting the metal aluminum surface of the anode guide rod and returning the measured voltage signal. The use of a tapered structure can make the contact point contact, so as to improve the measurement accuracy,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com