Method for determining lens errors in a particle-optical device

A particle optics and lens technology, which is applied in the field of determining the lens error in particle optics equipment, and can solve problems such as the lack of a clear image of the solder ball and the difficulty in determining the lens error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

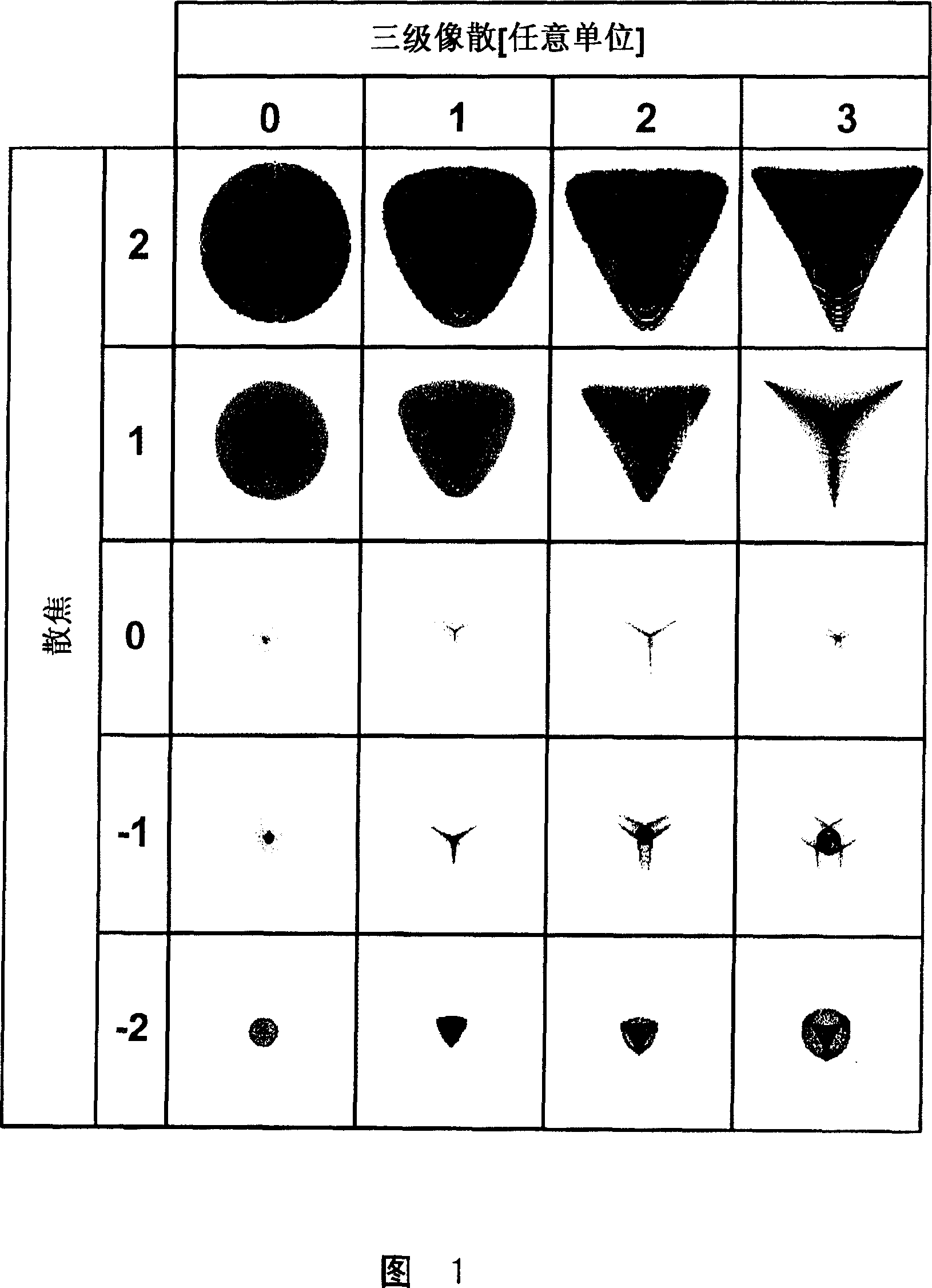

[0049] Figure 1 shows diagrammatically the cross-sections of the beam at different distances from the (paraxial) focal plane calculated by computer simulation.

[0050] In this simulation, the beams were subjected to the same degree of spherical aberration in all cases. Rows show cross-sections at different degrees of defocus, while columns show cross-sections at different values of tertiary astigmatism.

[0051] The focal plane is shown in the third row at "Defocus=0". The second row shows the cross-section of the beam in a plane that is placed some distance behind the focal plane as seen from the objective, while the first row shows the same distance behind the focal plane The cross section of the beam in the plane at . Similarly, the fourth and fifth rows show the cross-section of the beam in the plane between the paraxial focal plane and the objective.

[0052] Far to the left of the first column, there is no third-order astigmatism, and the beam experiences only sphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Biggest size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com