Extension developing method for sub-molecule single layer quanta point laser material

A technology of quantum dot material and growth method, applied in the field of epitaxial growth of sub-molecular single-layer quantum dot laser material, can solve the problems of narrow band gap, difficult control of distribution uniformity and density, disorder of quantum dots, etc. Sexual improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below in conjunction with accompanying drawing

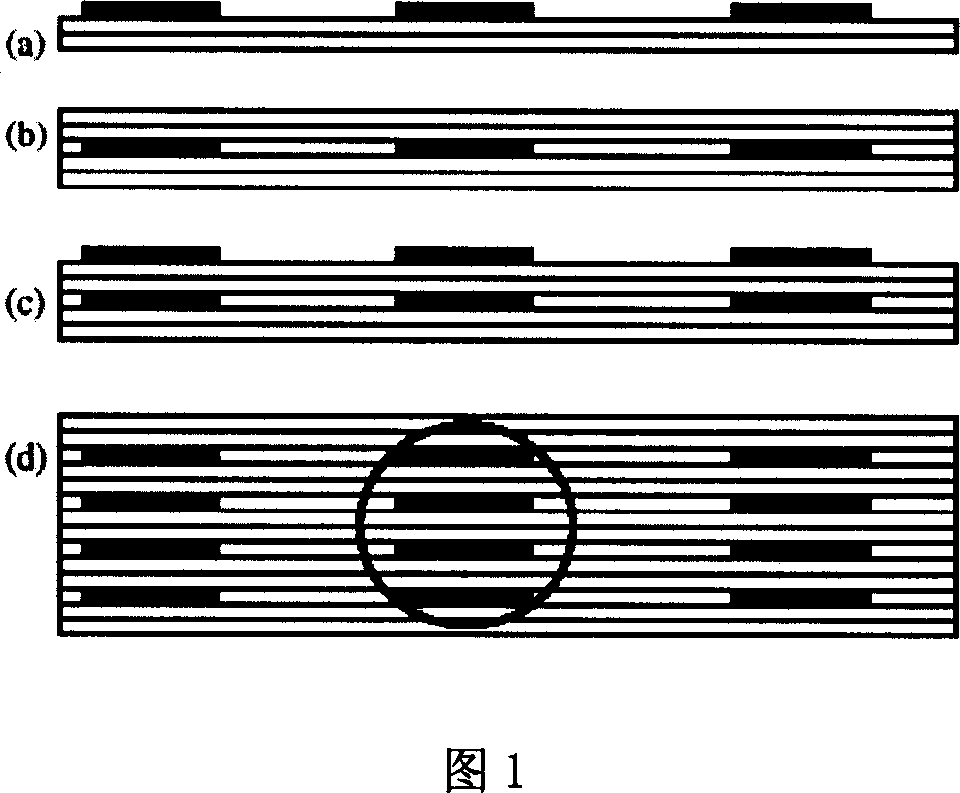

[0060] Fig. 1 is the core idea of the present invention, that is, the epitaxial growth formation process of submolecular monolayer quantum dots. It can be seen from the figure that when the InAs capping layer on GaAs is less than 1ML, under the optimized MBE growth conditions, this layer of InAs film will transform into 1ML high islands and distribute on the GaAs surface in the form of arrays (as shown in Figure 1(a)). Cover these InAs islands with a certain thickness of GaAs to make it a flat surface (as shown in Figure 1(b)), and then grow the second layer of InAs islands according to the method of growing the first layer of InAs islands, and the first layer of InAs islands A vertically coupled self-alignment effect occurs with the second layer of InAs islands (as shown in Figure 1(c)). Therefore, when the submolecular monolayer deposition method is repeated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com