Method and device for discharge measurement

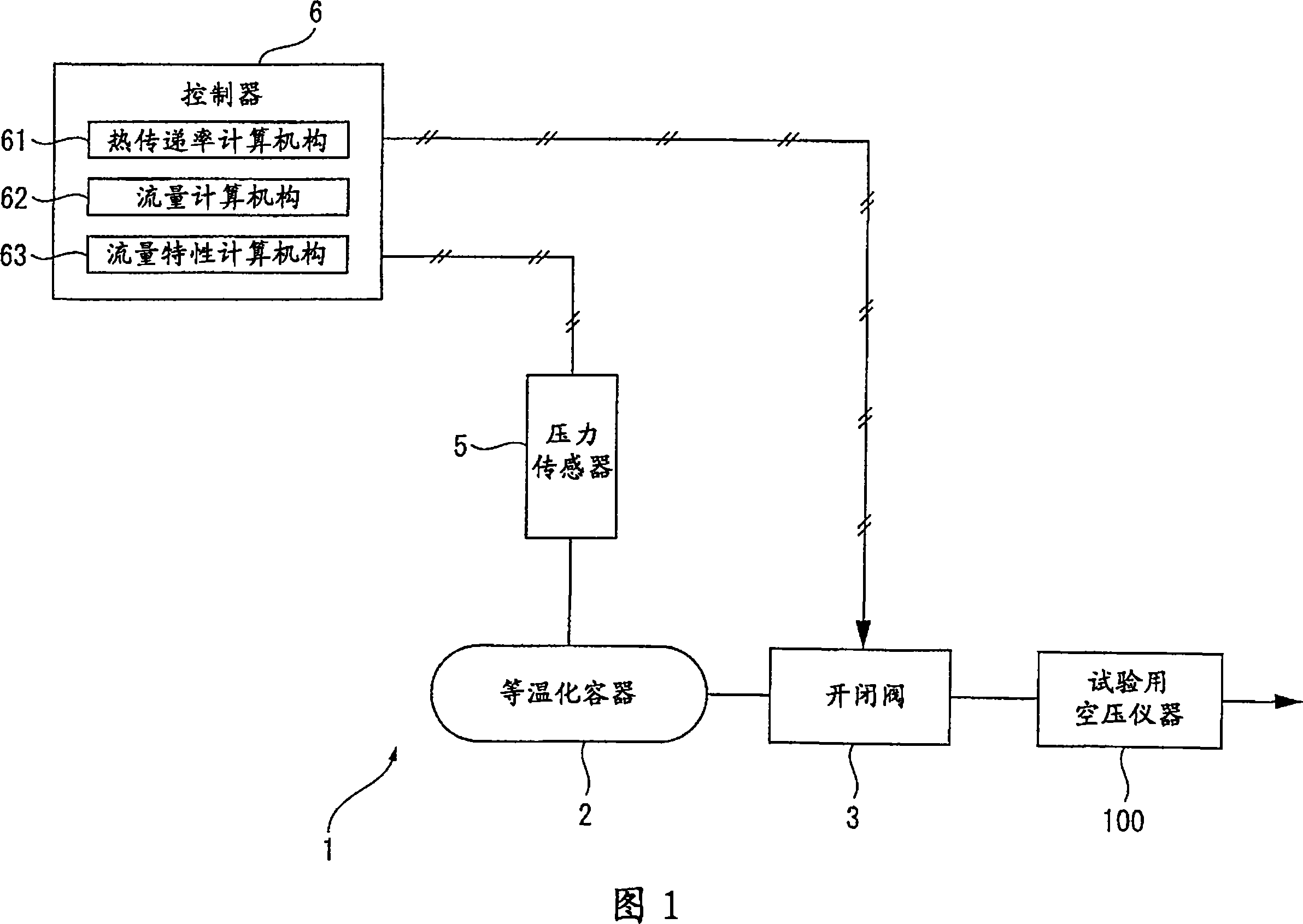

A flow measurement and flow technology, which is applied in the measurement of flow/mass flow, measurement device, volume measurement, etc., can solve problems such as uneconomical, increased price of isothermal containers, and inability to measure flow characteristics with high accuracy, and achieves a simple calculation formula. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Examples of the present invention will be described below. In this example, the flow rate characteristic of the pneumatic device 100 for a test was measured using the flow rate measuring device 1 of the above-mentioned embodiment.

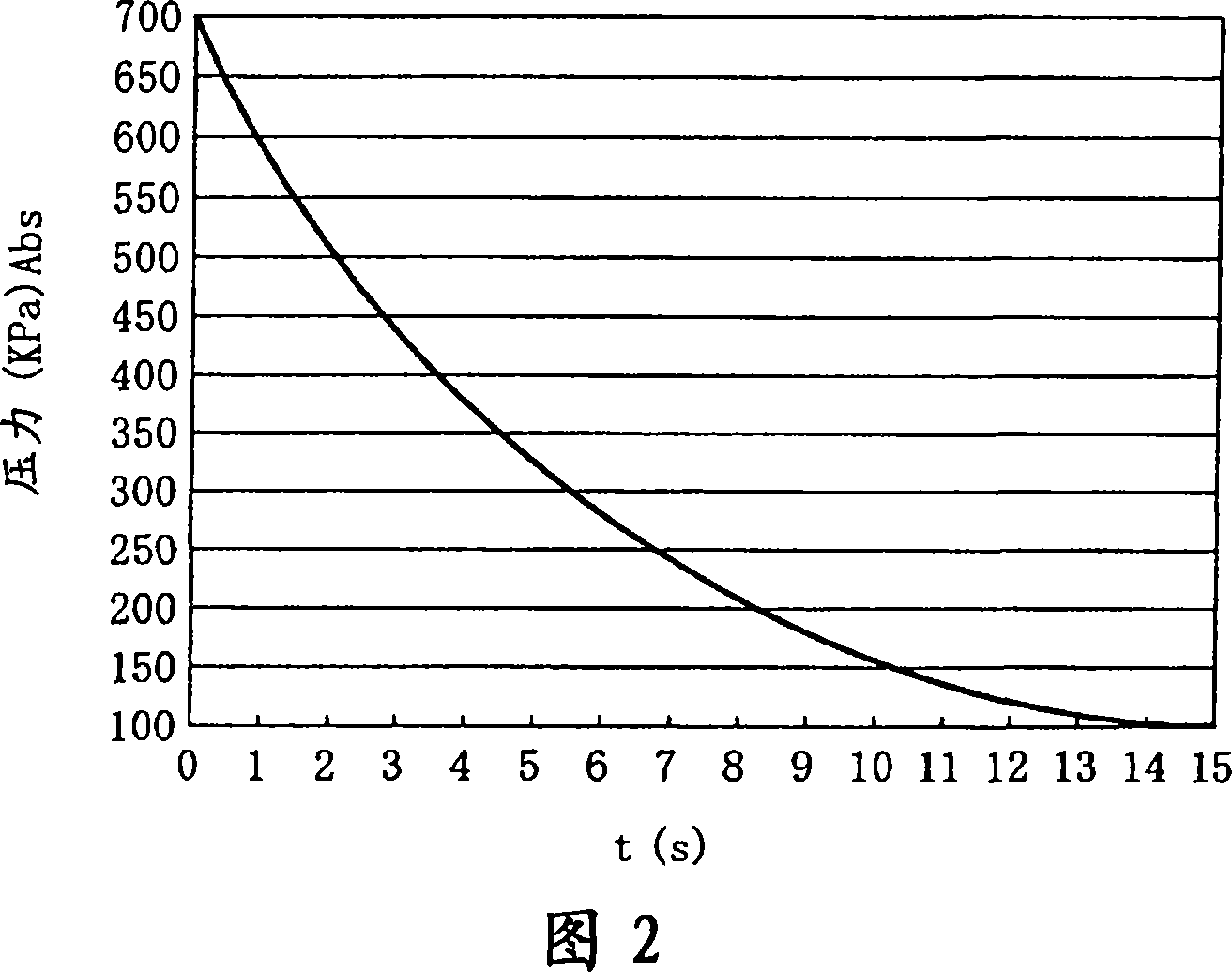

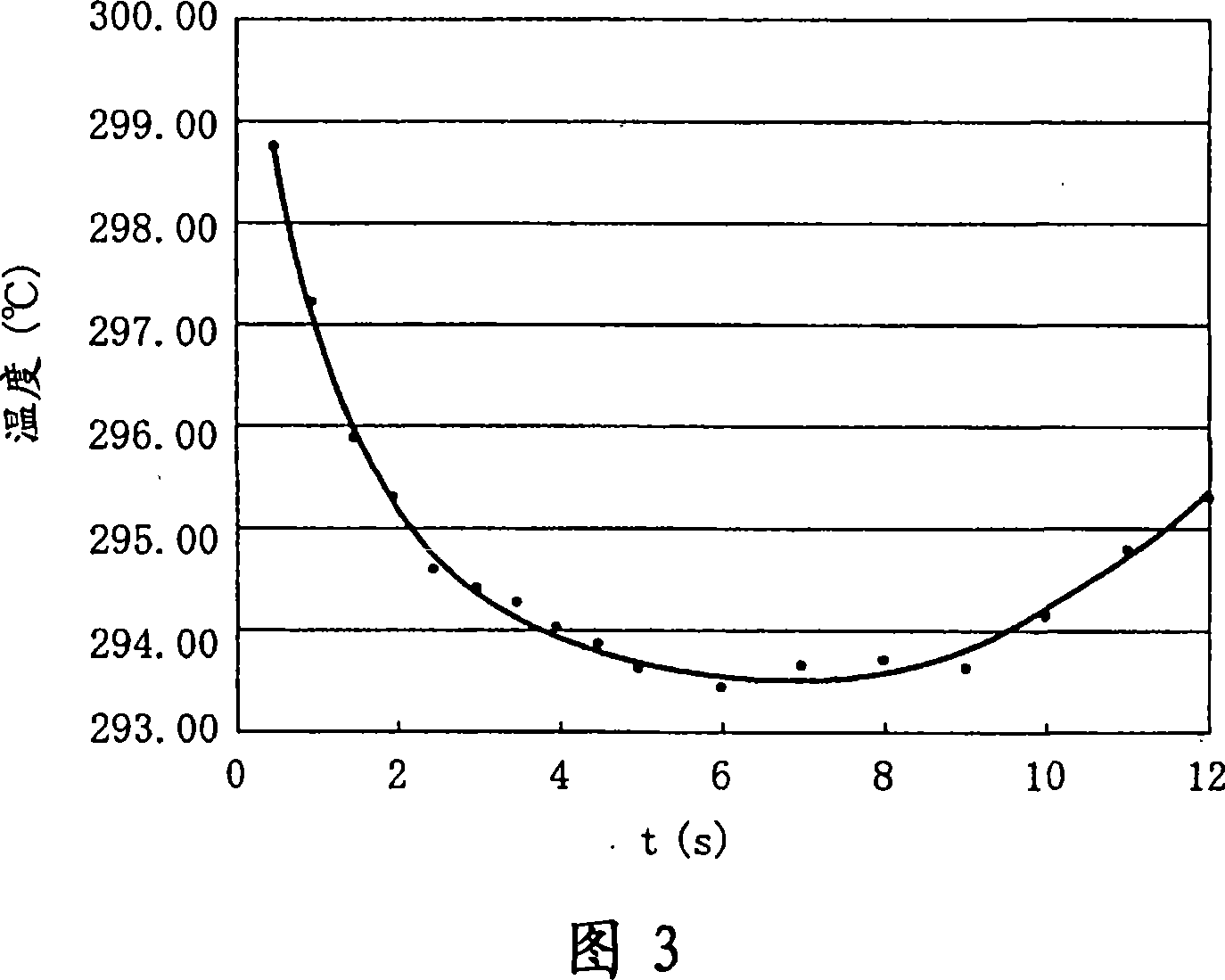

[0102] The volume of the isothermal container 2 is 4.91, and the release initial pressure is 0.6 MPa. The thermal conductivity material filled inside is 0.75 kg of copper wire with a diameter of 50 μm, and the weight filling rate is 0.150 kg / dm 3 .

[0103] As the pneumatic device 100 for the test, a solenoid valve of model VT307-5G-01 was used. In addition, room temperature (atmospheric temperature θ a ) is 280C.

[0104] In the temperature response determination process, after the compressed air in the isothermal container 2 starts to be released, the on-off valve 3 is closed every 0.5 seconds to stop releasing the compressed air, and the pressure at the time of release stop is measured by the pressure sensor 5 (release stop constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com