Formulation of plant source hard capsule case and preparing method thereof

A hard capsule shell, plant-derived technology, which is applied in the directions of non-active ingredient medical preparations, capsule delivery, pharmaceutical formulations, etc., can solve the problems of high cost and complicated process, and achieves a solution that avoids pollution, has high transparency, and is conducive to drug stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

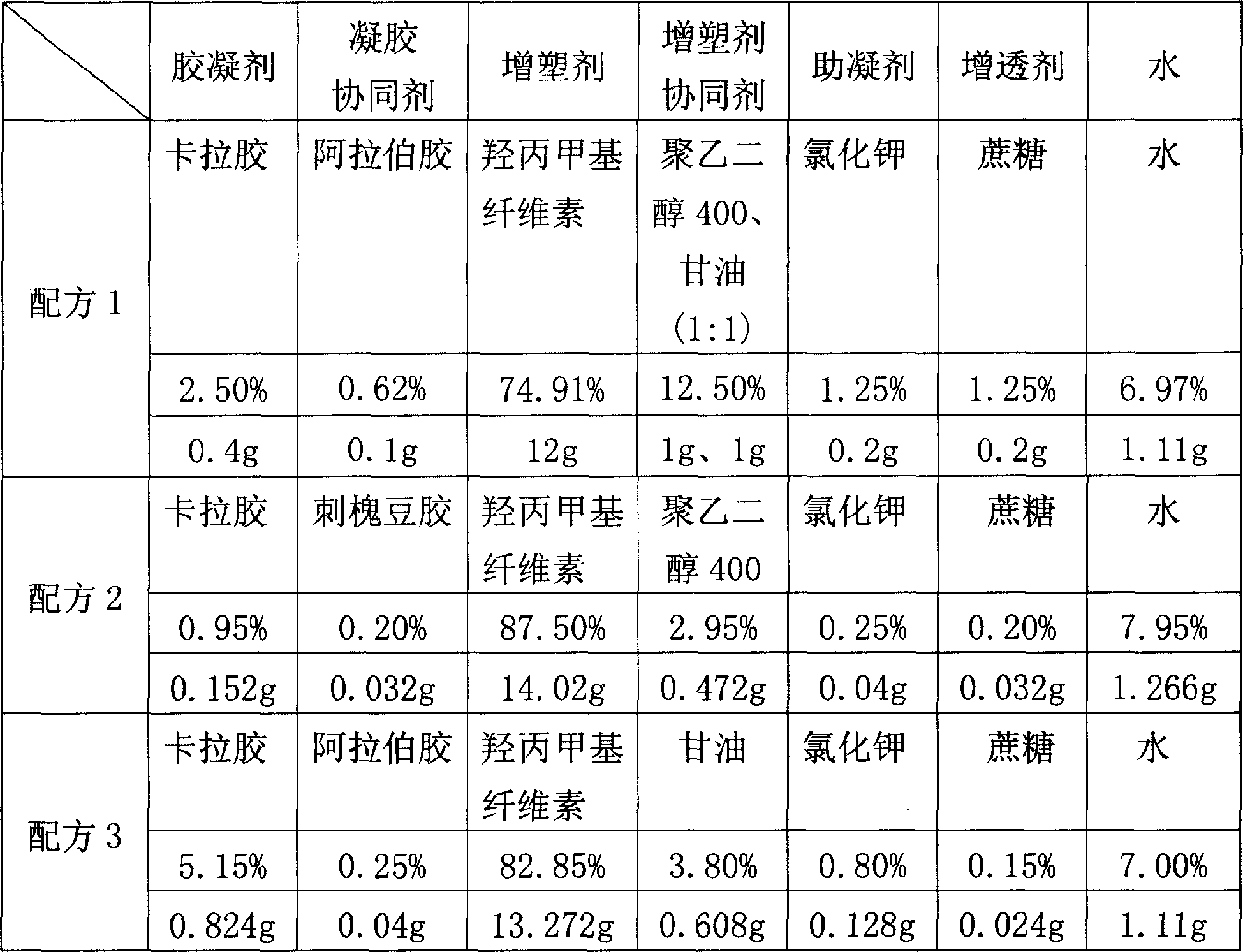

[0032] Example 1. An example of the product formulation of the novel plant-derived hard capsule shell of the present invention is shown in Table 1 (% in the table is a percentage by weight).

[0033] Table 1 Product formula

[0034]

Embodiment 2

[0035] Embodiment 2, the preparation method of plant source hard capsule shell is as follows:

[0036] (1) Weighing:

[0037] According to formula 1 in Table 1, measure 80ml of distilled water and pour it into a beaker, respectively weigh 0.2g potassium chloride, 0.2g sucrose, 0.1g gum arabic, 0.4g carrageenan, 1g polyethylene glycol 400, and 1g glycerol in turn. Put into a beaker and stir.

[0038] (2) Heating to dissolve:

[0039] The beaker was placed in a 60°C water bath, heated and stirred, and 12 g of hydroxypropyl methylcellulose 60HD5 was added to the beaker at 80°C, and stirred to dissolve.

[0040] (3) Gum raising:

[0041] The beaker was thermostated in a water bath at 84°C for 45 minutes.

[0042] (4) Defoaming:

[0043] First add 3-5 drops of ethanol dropwise to the beaker, stir and place for three minutes, then add 2-3 drops dropwise (this step should be determined by the amount of air bubbles).

[0044] (5) Dipping glue:

[0045] Lower the temperature of ...

Embodiment 3

[0051] (1) Weighing:

[0052] According to formula 2 in Table 1, measure 80ml of distilled water and pour it into a beaker, weigh 0.04g of potassium chloride, 0.032g of sucrose, 0.032g of locust bean gum, 0.152g of carrageenan, and 0.472g of polyethylene glycol 400, respectively. Put into a beaker and stir.

[0053] (2) Heating to dissolve:

[0054] The beaker was placed in a 60°C water bath, heated and stirred. At 80°C, 14.02 g of hypromellose 60HD5 was added to the beaker and stirred to dissolve.

[0055] (3)-(7) Steps are the same as in Example 2.

[0056] After testing, the water content of the obtained product was 7.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com