Preparation method of puerarin extract

A production method and extract technology, applied in the field of extraction and separation of puerarin in Chinese herbal medicine, can solve the problems of high production cost, many process steps, and long production cycle, and achieve low production cost, simple process operation, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

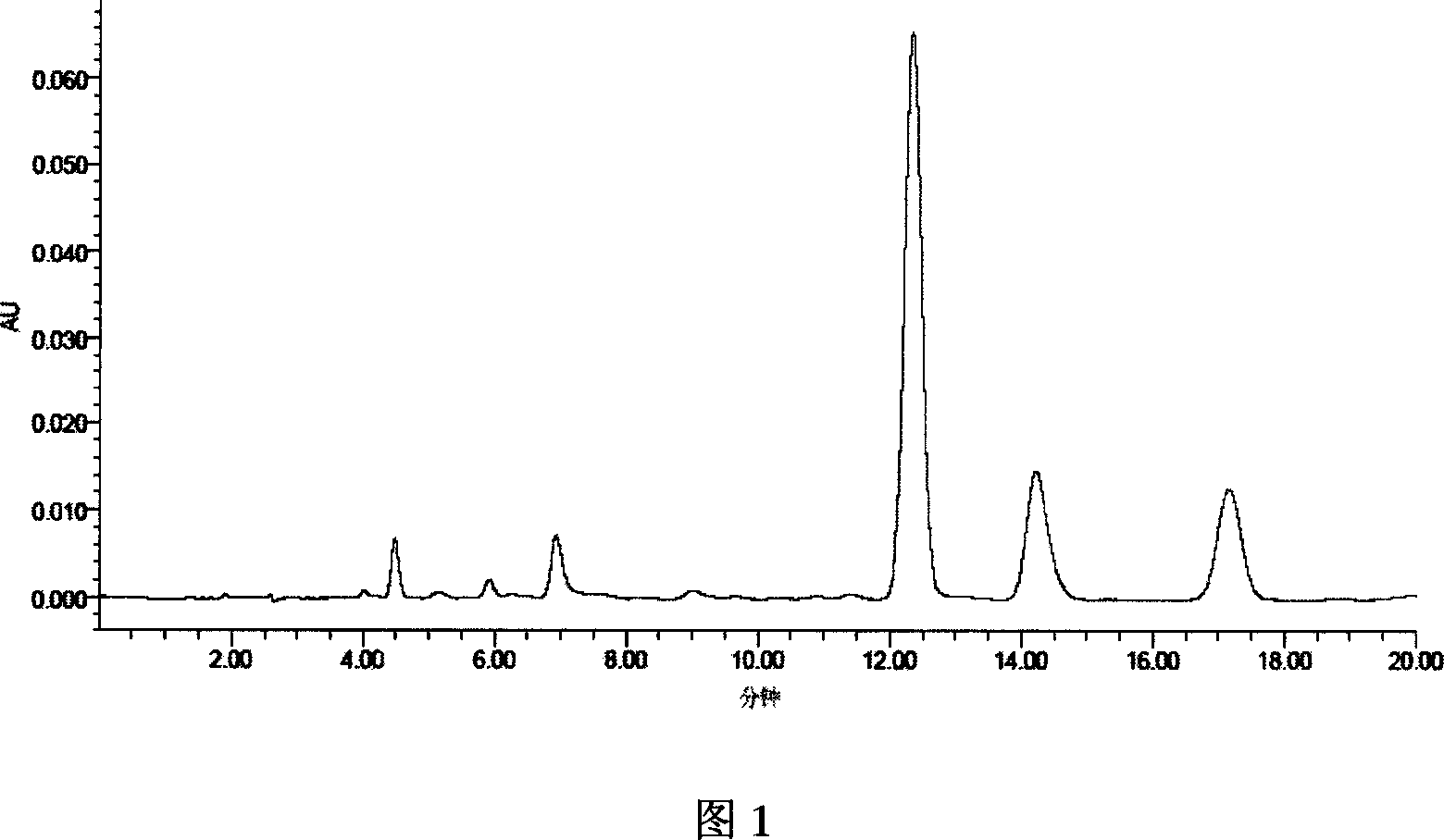

Embodiment 1

[0025] Weigh 50kg Pueraria mirifica medicinal material, after crushing, add 400L water to decoct for 3 hours, then decoct with 300L water for 0.5 hour, combine the decoction liquid, cool, pass through macroporous resin D-392 with a weight of 100kg, first decoct with 3 Wash with 5 times the column volume of water, then 5 times the column volume of 60% ethanol, collect the ethanol eluent, reclaim the ethanol to obtain powder, add 4 times the amount of water, and pass through a macroporous adsorption resin with a weight of 12.5kg S-8, first eluted with 3 times column volume of water, then eluted with 6 times column volume of 20% ethanol, collected 20% ethanol eluate, recovered ethanol to obtain puerarin extract, wherein the puerarin content was 60%, The powder extraction rate was 1.9%.

Embodiment 2

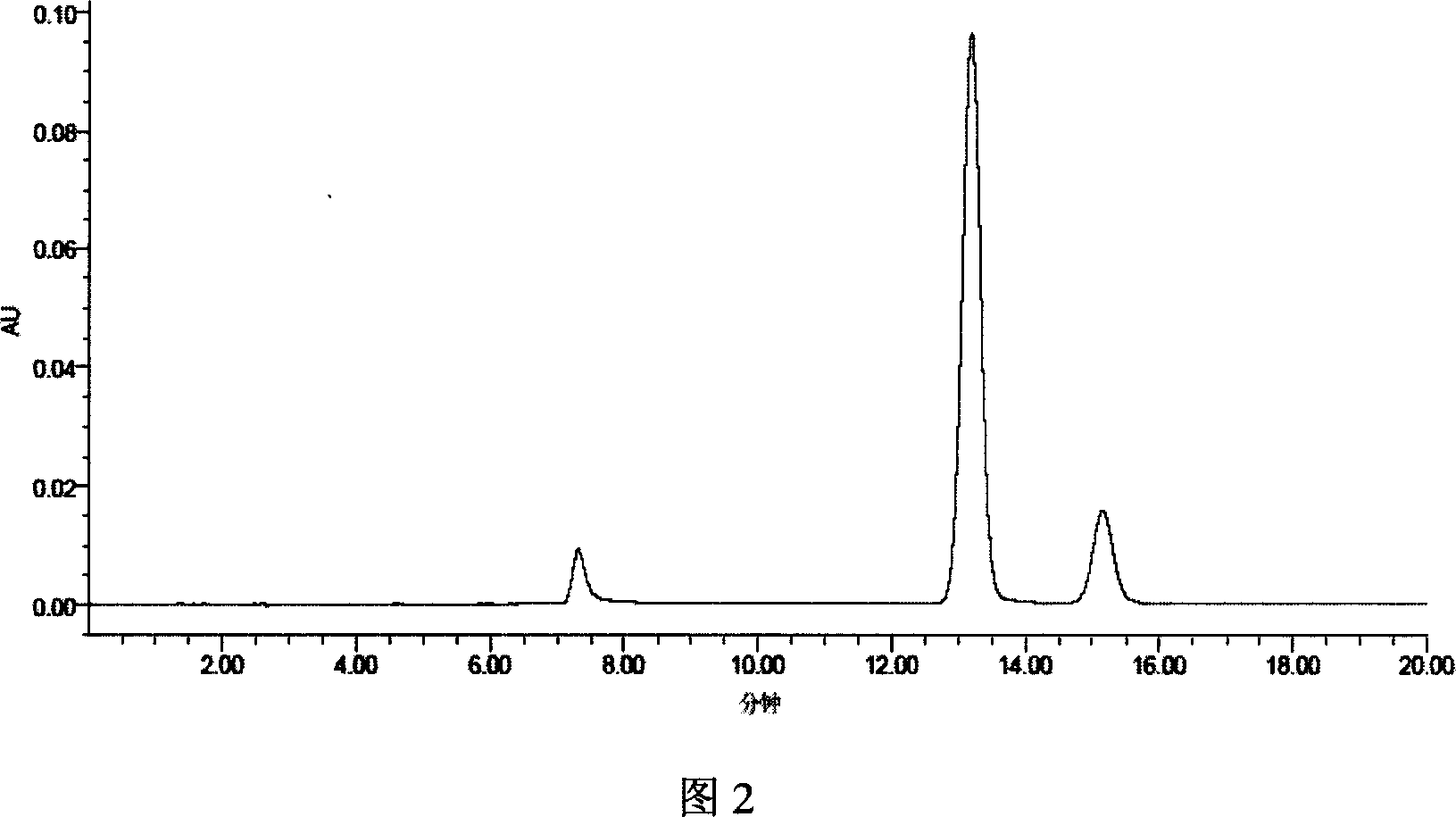

[0027] Weigh 50kg powder kudzu root medicinal material, after pulverization, add 400L water to decoct for 2 hours, then decoct with 300L water for 1 hour, combine the decoction liquid, cool, pass through macroporous resin D-392 with a weight of 100kg, first decoct with 3 Elute with 5 times column volume of water, then 5 times column volume of 60% ethanol, collect the ethanol eluate, recover ethanol to obtain powder, add 4 times the amount of 1% (V / V) concentrated sulfuric acid and hydrolyze After 3 hours, adjust the pH of the hydrolyzed solution to 6.5, dilute the volume by 5 times on the basis of the hydrolyzed solution, and filter to obtain the filtrate. The filtrate passes through the macroporous adsorption resin S-8 with a weight of 12.5 kg, and washes it with water for 3 times the column volume. Then, elute with 6 times column volume of 20% ethanol, collect the 20% ethanol eluate, recover the ethanol to obtain the puerarin extract, wherein the puerarin content is 77%, and ...

Embodiment 3

[0029] Weigh 200kg powder kudzu root medicinal material, after pulverization, add 1600L water to decoct for 2 hours, then decoct with 1200L water for 1 hour, combine the decoction liquid, cool, pass through macroporous resin D-392 with a weight of 300kg, first decoct with 2 Elute with 4 times column volume of water, then 4 times column volume of 60% ethanol, collect the ethanol eluate, recover ethanol to obtain powder, add 4 times the amount of 1.5% (V / V) concentrated sulfuric acid and hydrolyze After 4 hours, adjust the pH of the hydrolyzate to 6.5, dilute the volume by 5 times on the basis of the hydrolyzate, and filter to obtain the filtrate. The filtrate passes through the macroporous adsorption resin S-8 with a weight of 50 kg, and first elutes with 3 times the column volume of water , and then eluted with 7 times column volume of 20% ethanol, collected the 20% ethanol eluate, recovered the ethanol to obtain the puerarin extract, wherein the puerarin content was 79%, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com