Electrostatic capacity type pressure sensor and sphygmomanometer with the same sensor

A pressure sensor and electrostatic capacitance type technology, applied in the field of sphygmomanometers, can solve the problems affecting the cost, accuracy and reliability of electronic sphygmomanometers, and achieve the effects of novel structure, stable circuit and gas path, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

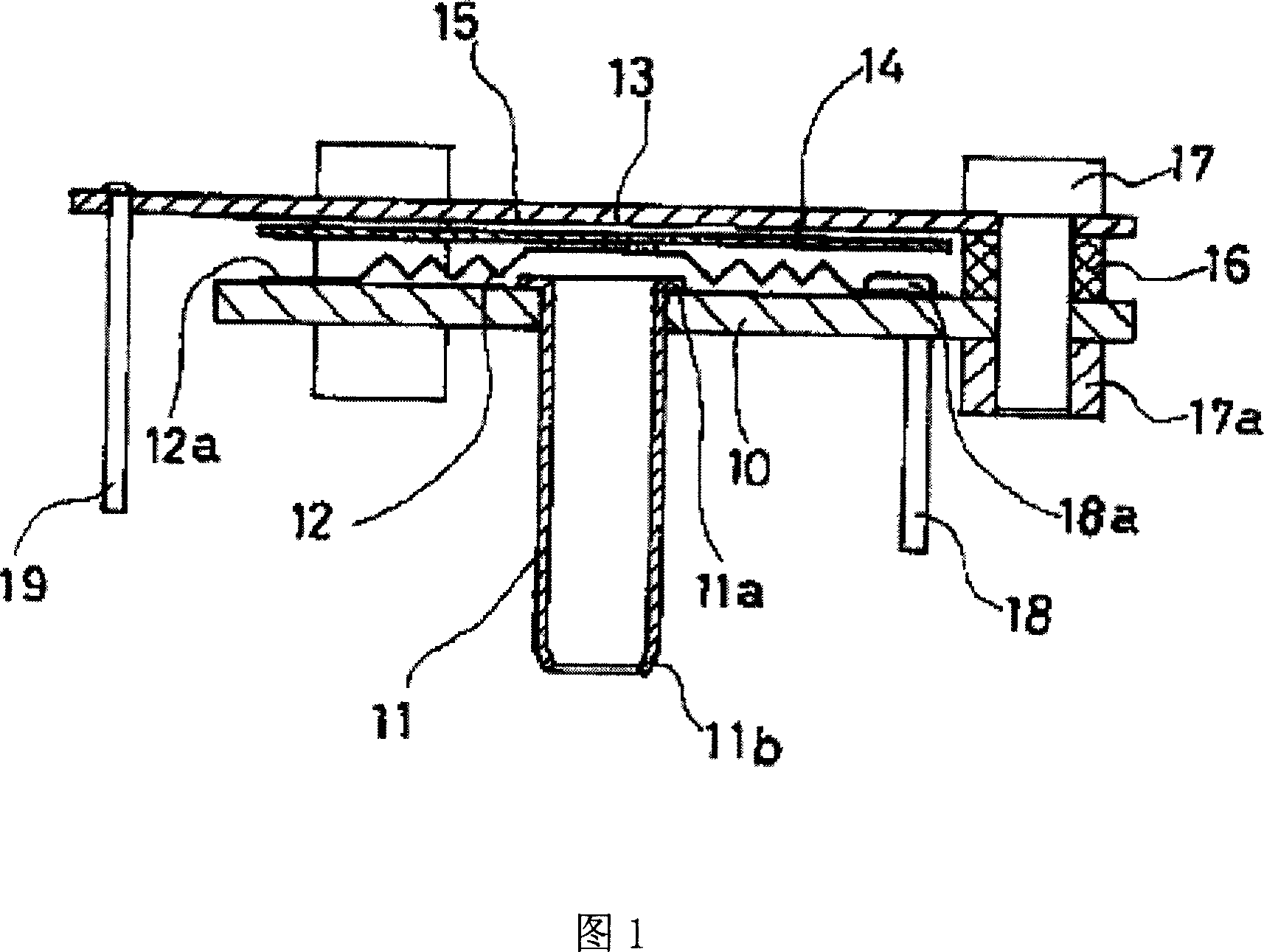

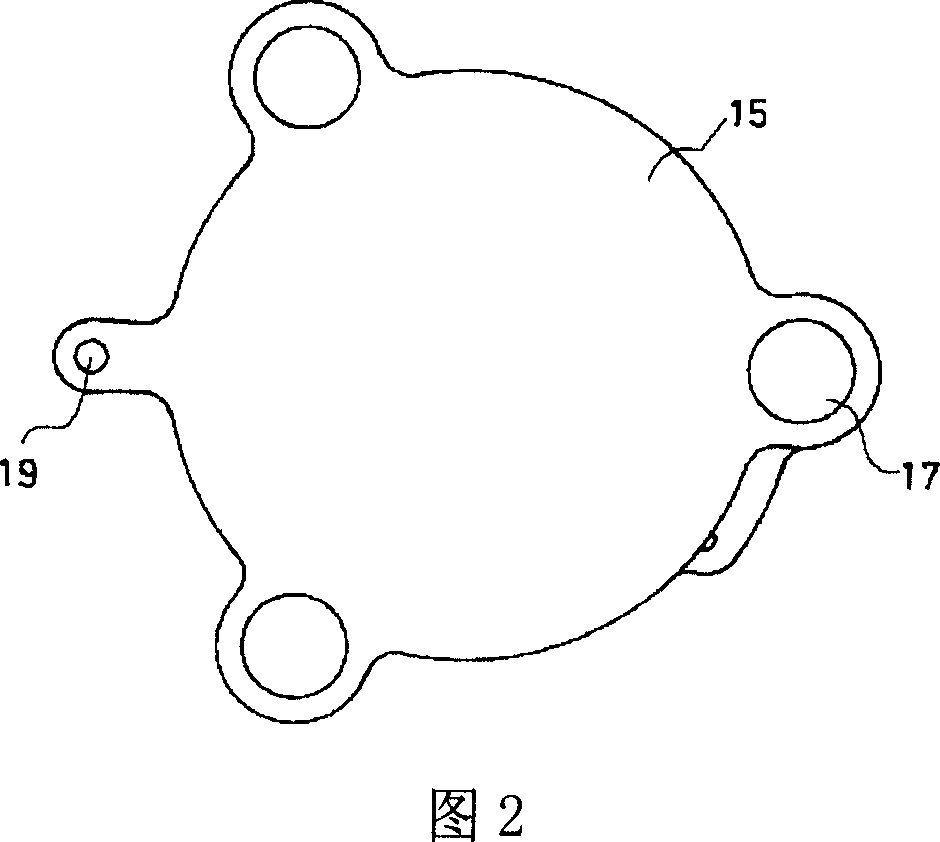

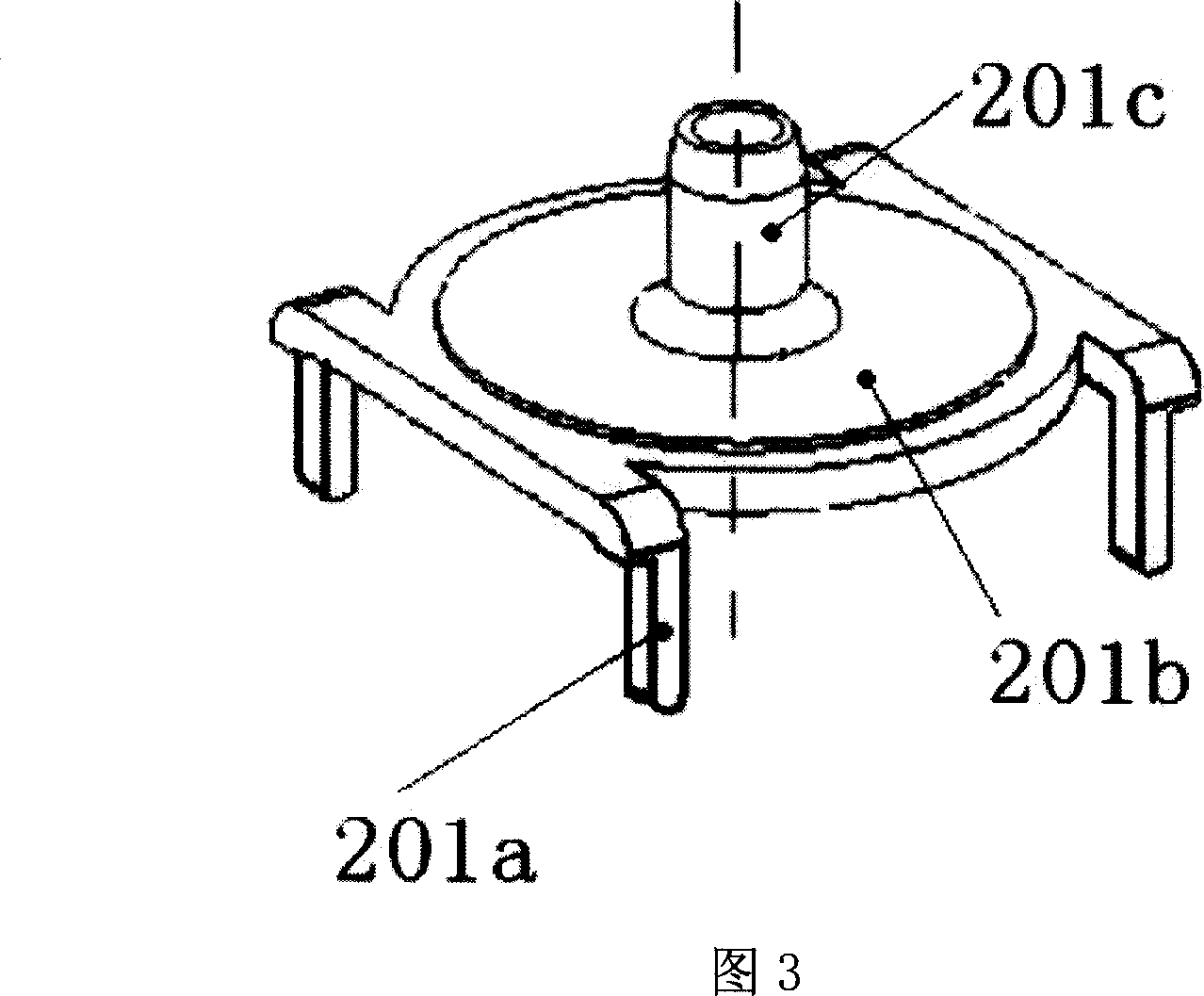

[0033] Embodiment 1. An electrostatic capacitive pressure sensor, referring to FIGS. 3-7 , includes a sensor assembly 20 and a printed circuit board 21. The sensor assembly 20 includes a base assembly 201, an elastic body 202 that can be deformed by changes in pressure, and a The moving electrode 203 and the elastic body 202 are corrugated plates made of conductors.

[0034] Referring to Figures 3-5, the base assembly 201 is a hardware part integrating the gas nozzle 201c, the base 201b, and the movable electrode terminal 201a, and the gas nozzle 201c and the movable electrode terminal 201a extend outward from the base made. The corrugated plate 202 is welded and fixed to the base 201b, and the movable electrode 203 is welded and fixed to the corrugated plate 202. A closed air chamber 20a is formed by the base 201b and the corrugated plate 202, and the air inlet of the air nozzle 201c enters the airtight air chamber 20a. It is a flare with progressive enlargement and smooth t...

Embodiment 2

[0043] Embodiment 2, an electronic sphygmomanometer, with reference to Fig. 3-8, comprises air bag 30, pressure sensor 31, pressurization pump 34, air-hold pressure reducing valve 35, battery 38, voltage detection circuit 37, voltage stabilizing circuit 36, microprocessor device 32, display 33 and switch 39. Wherein, the air bag 30, the booster pump 34, the gas-hold pressure reducing valve 35, the battery 38, the voltage detection circuit 37, the voltage stabilizing circuit 36, the microprocessor 32, the display 33 and the switch 39 are known and mature technologies of the existing electronic sphygmomanometer, The pressure sensor adopts the capacitance type pressure sensor structure shown in Fig. 3-7, wherein the printed circuit board 21 is the main circuit board of the sphygmomanometer. The top of the gas nozzle 201c communicates with the air bag 30, and the static capacitance signal generated by the gas pressure change detected by the movable electrode 203 and the fixed elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com