Class vacuum composite sound isolating material and producing process thereof

A sound-insulating material and preparation technology, which is applied in the direction of sound-emitting devices and instruments, can solve the problems of inability to withstand mechanical vibration, inability to cut, and high cost, and achieve the effects of light weight, easy installation, and high sound-absorbing and sound-insulating capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

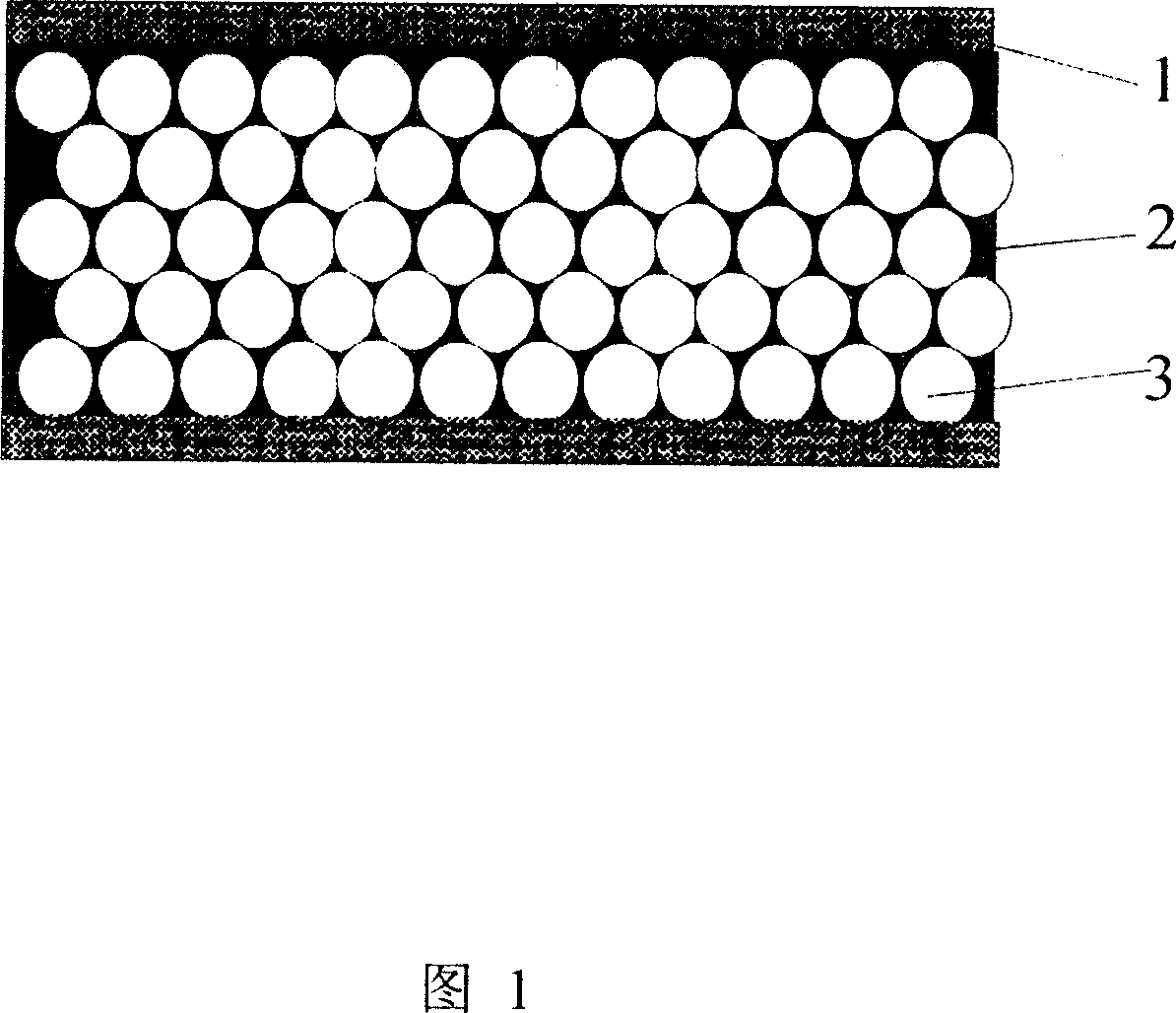

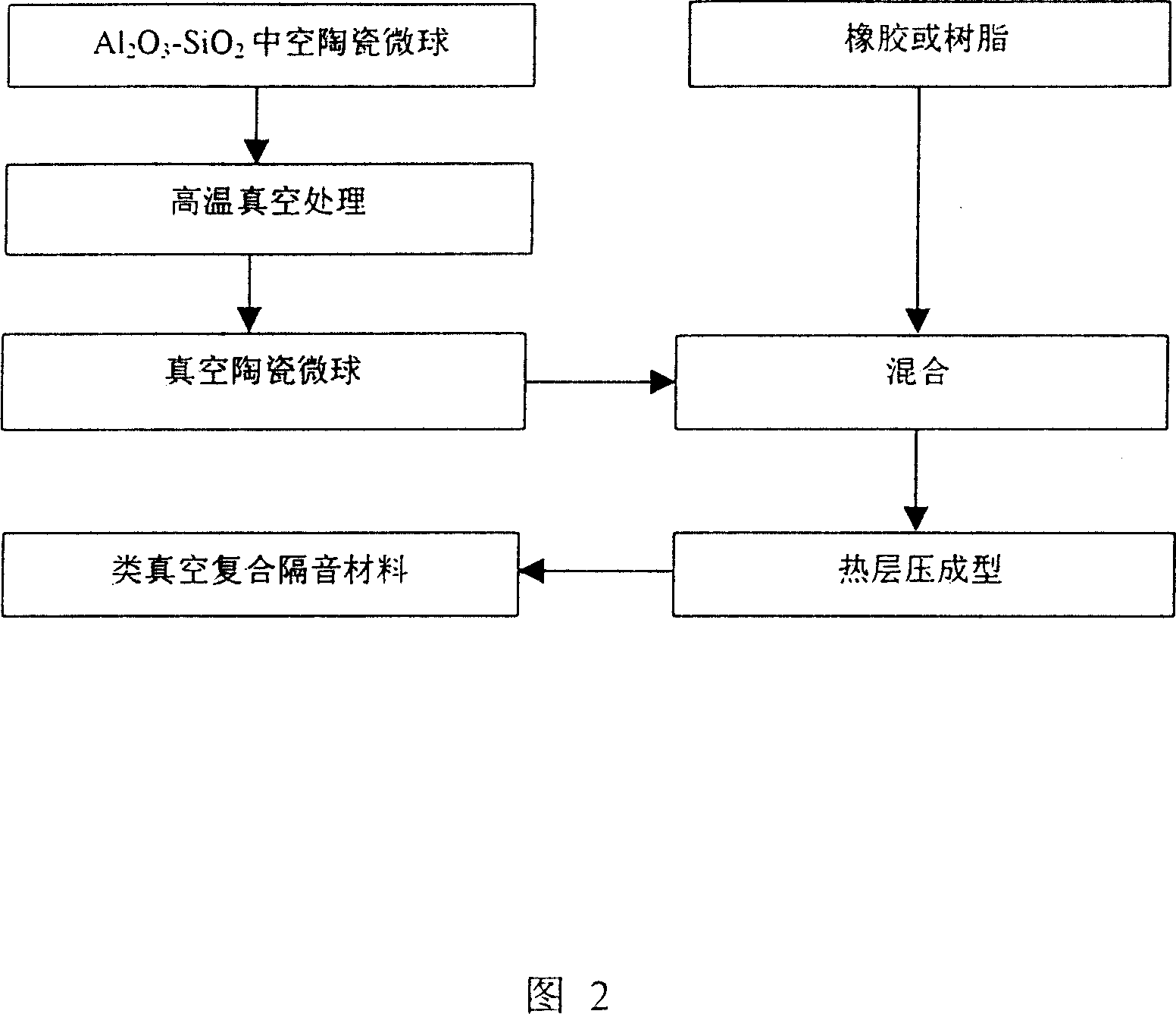

[0025] 1. Use Al with a diameter of 0.2mm and a wall thickness of 10μm 2 o 3 -SiO 2 The hollow ceramic microspheres are pumped into a vacuum at a high temperature of 800°C to form vacuum ceramic microspheres 3;

[0026] 2. Mix the above-mentioned vacuum ceramic microspheres 3 with a viscoelastic substance 2 such as rubber (rubber powder), the volume of the vacuum ceramic microspheres 3 accounts for 50% of the total volume of the mixture, and form them by hot pressing at 200°C.

[0027] The fiber fabric (cloth) 1 can be paved on the outer surface of the composite material after thermocompression forming.

Embodiment 2

[0029] 1. Use Al with a diameter of 0.2mm and a wall thickness of 10μm 2 o 3 -SiO 2 The hollow ceramic microspheres are pumped into a vacuum at a high temperature of 800°C to form vacuum ceramic microspheres 3;

[0030] 2. The above-mentioned vacuum ceramic microspheres 3 are mixed with viscoelastic substances 2 such as resin (polyhexene powder or resin of similar nature), the volume of vacuum ceramic microspheres 3 accounts for 65% of the total volume of the mixture, and heated at 200°C Compression molding.

[0031] The fiber fabric (cloth) 1 can be paved on the outer surface of the composite material after thermocompression forming.

Embodiment 3

[0033] 1. Use Al with a diameter of 0.3mm and a wall thickness of 20μm 2 o 3 -SiO 2 The hollow ceramic microspheres are pumped into a vacuum at a high temperature of 1000°C to form vacuum ceramic microspheres 3;

[0034] 2. Mix the above-mentioned vacuum ceramic microspheres 3 with a viscoelastic substance 2 such as asphalt, the volume of the vacuum ceramic microspheres 3 accounts for 60% of the total volume of the mixture, and heat press at 400°C.

[0035] The fiber fabric 1 can be paved on the outer surface of the composite material formed by thermocompression.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com