Method for producing tri-splitting drive rectifier transformer

A technology for rectifying transformers and manufacturing methods, which is applied in the field of transformers, and can solve problems such as difficulty in matching short-circuit impedance values, overheating of transformers, and uneven distribution of short-circuit currents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

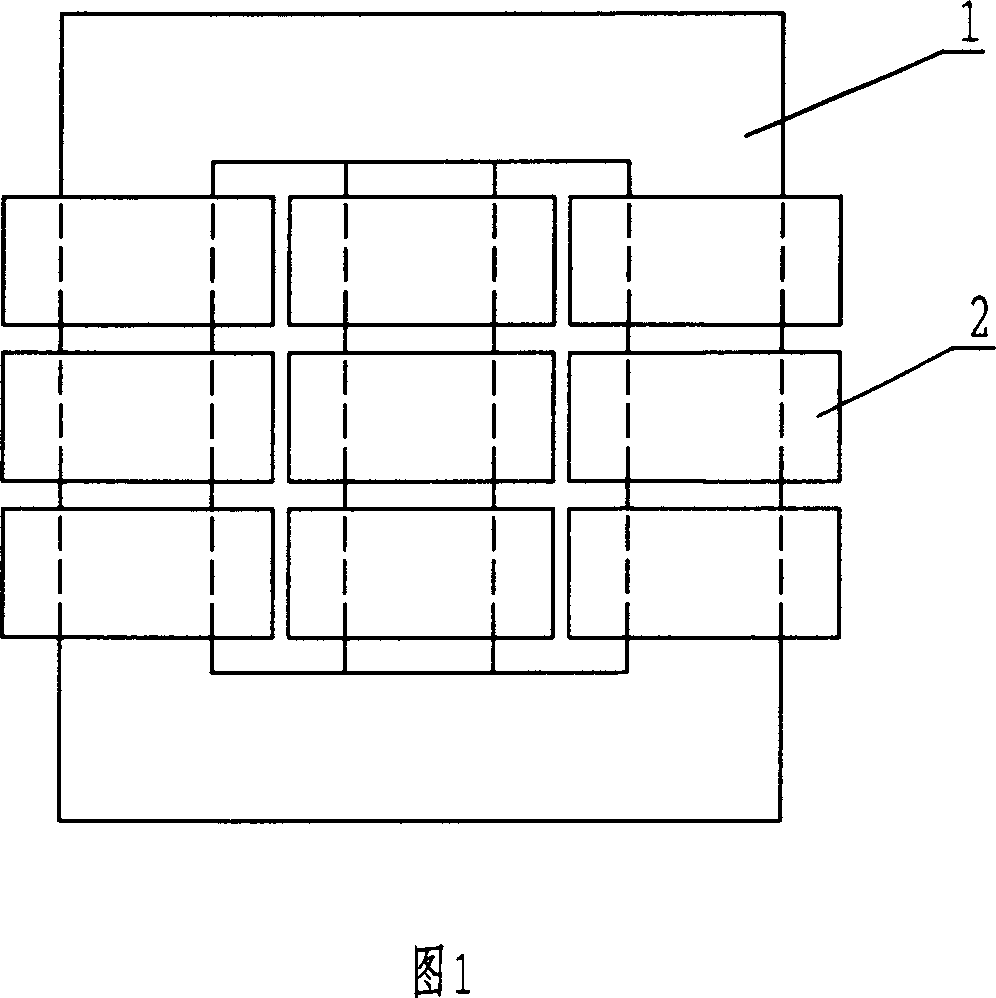

[0062] Figure 1 can be regarded as a simplified assembly diagram of the device body. The mutual position of the iron core and windings is marked in the figure. The iron core adopts a three-column structure, and the high and low voltage windings are arranged concentrically and sleeved on the three core columns.

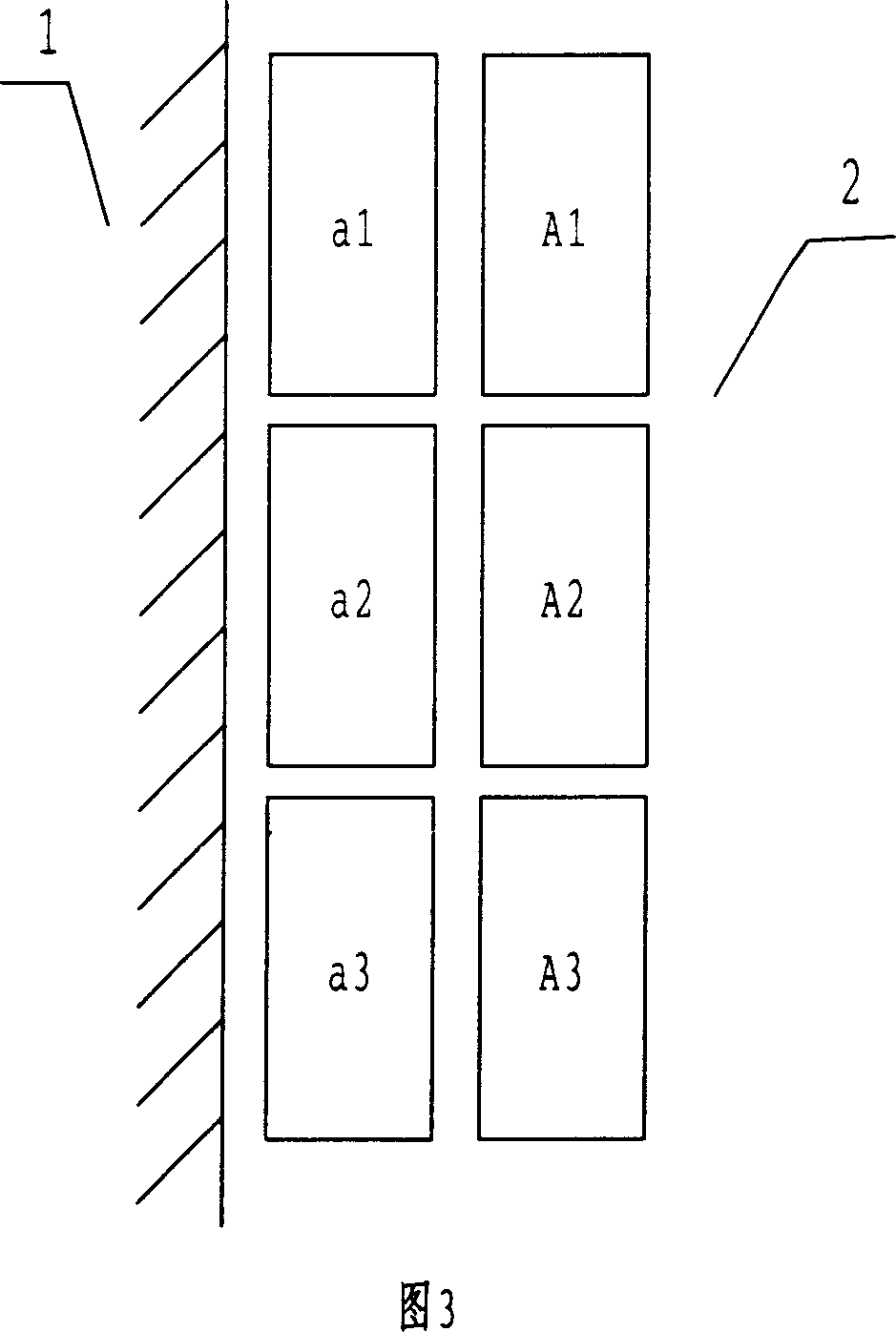

[0063] Figure 3 is a drawing of the winding set on the iron core column, and each iron core column is equipped with three low-voltage windings a1~a3 (or b1~b3, c1~c3) and three high-voltage windings A1~A3 (or B1~B3, C1~ C3). The three low-voltage windings are arranged axially; the three high-voltage windings are also arranged axially and correspond to the low-voltage windings in height. Depending on its position in the axial direction, it is called upper winding, middle winding and lower winding.

[0064]The low-voltage windings a1~a3, b1~b3 and c1~c3 on the three core columns are respectively set on the inner sides of the high-voltage windings A1~A3, B1~B3 and C1~C3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com