Method for producing controllable microhole structural piezoelectric functional film

A technology of microporous structure and functional film, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., can solve the problem of inability to prepare piezoelectric electrets , high thermal stability electret to form closed microporous structure and other problems, to achieve the effect of novel concept, high thermal stability, and improved thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

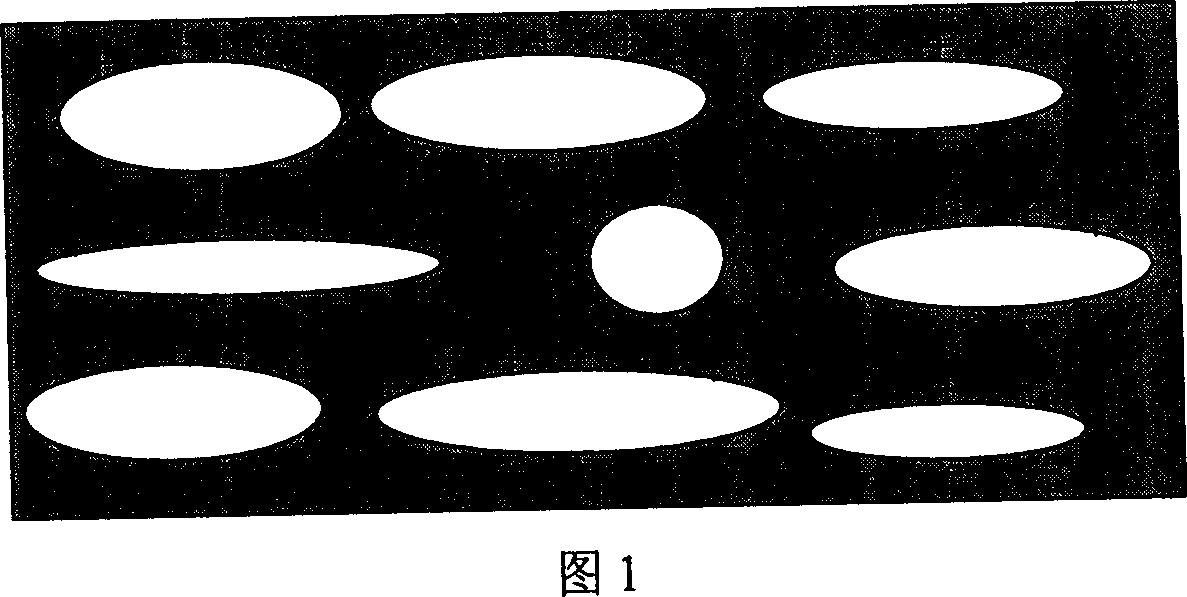

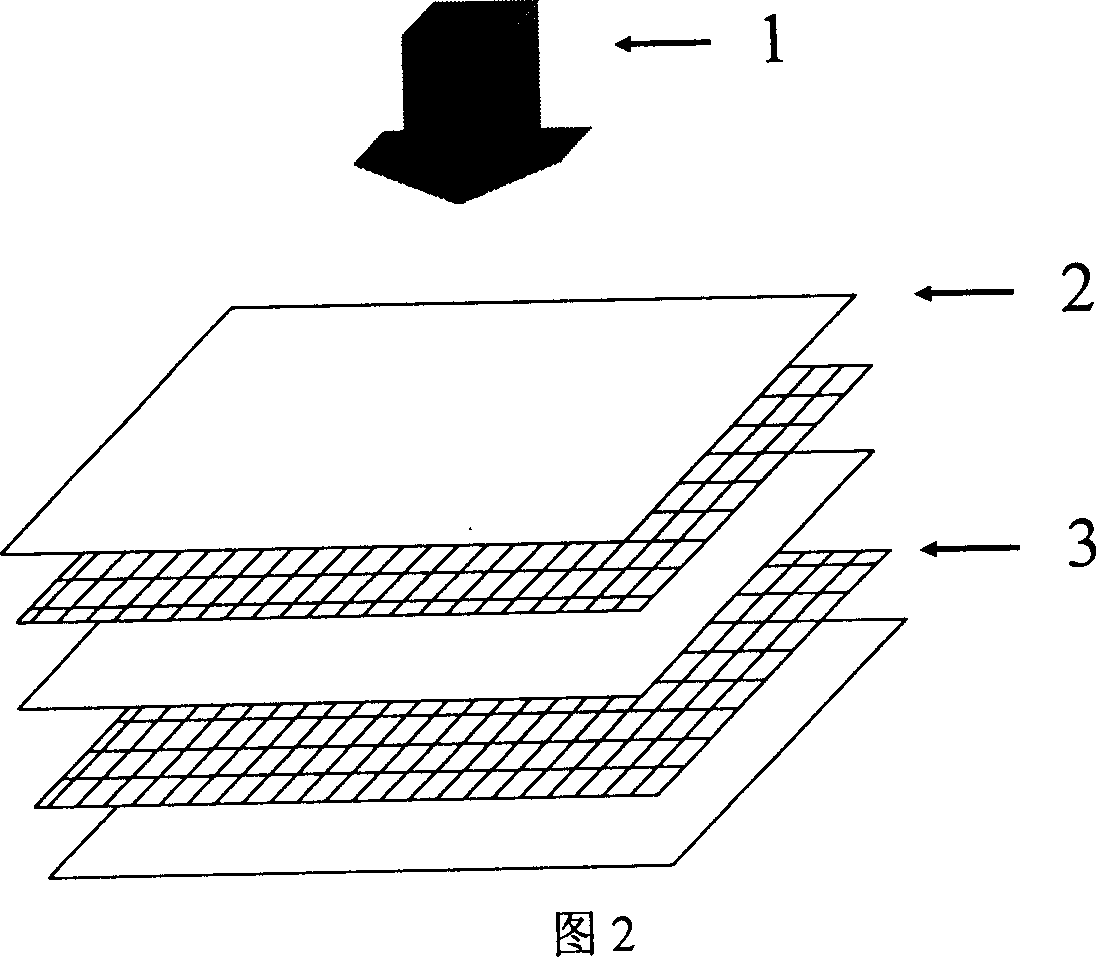

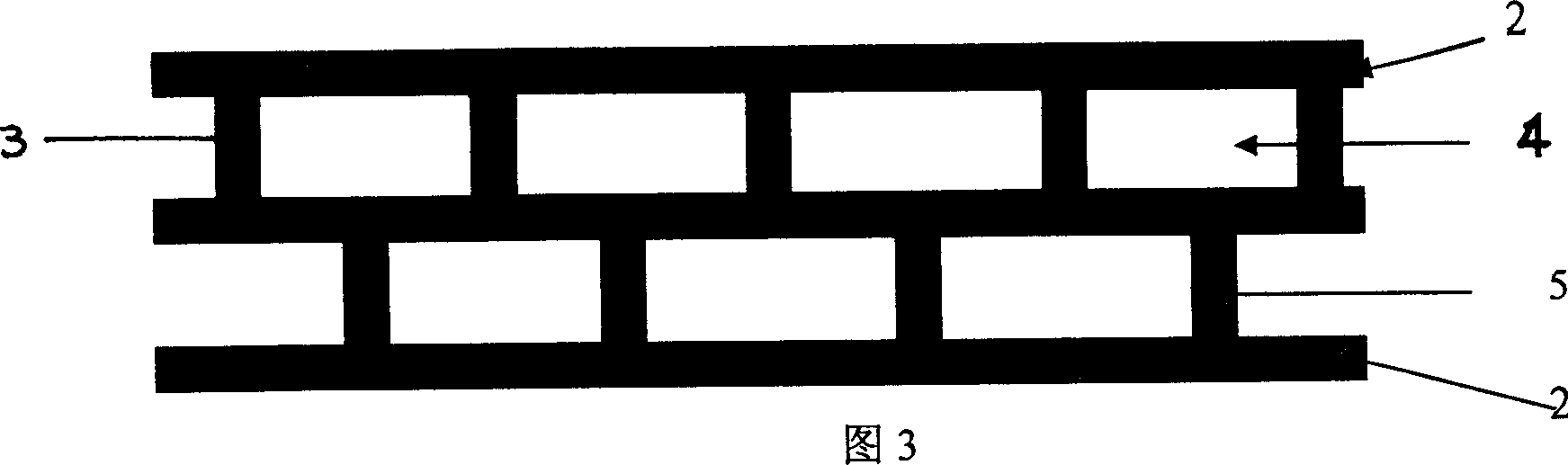

Embodiment 1

[0035] Embodiment 1 adopts a dense PTFE film (three layers) with a thickness of 25 μm and a PTFE mesh film (20 meshes, 0.08 mm wire diameter of the net, 1 mm aperture, two layers) with a thickness of 25 μm. The applied pressure is 27MPa; the applied temperature is 380°C; the applied time is 4h. A polymer composite membrane with a microporous structure is obtained. Corona charging is then performed. The corona electrode is needle-shaped; the corona voltage is 32kV; there is no grid control voltage; the charging temperature is 25°C; the charging time is 60s; the distance between the corona electrode and the sample is 7cm. 100nm aluminum electrodes were vacuum-evaporated on both sides of the microporous membrane. A piezoelectric electret film is obtained.

Embodiment 2

[0036] Embodiment 2 adopts a dense PTFE film (three layers) with a thickness of 25 μm and a FEP mesh film with a thickness of 12.5 μm (10 meshes, wire diameter of the net is 0.2 mm, aperture 0.05 mm, two layers). The applied pressure is 6kPa; the temperature is 320°C; the pressure time is 1h. A polymer composite membrane with a microporous structure is obtained. Corona charging is then performed. The corona electrode is needle-shaped; the corona voltage is 32kV; there is no grid control voltage; the charging temperature is 25°C; the charging time is 60s; the distance between the corona electrode and the sample is 7cm. 100nm aluminum electrodes were vacuum-evaporated on both sides of the microporous membrane. A piezoelectric electret film is obtained.

Embodiment 3

[0037]Embodiment 3 adopts a dense PEN film (three layers) with a thickness of 12.5 μm and a PTFE mesh film with a thickness of 12.5 μm (30 meshes, 0.1 mm wire diameter of the net, 90% porosity, two layers). The applied pressure is 15kPa; the temperature is 260°C; the pressure time is 0.5h. A polymer composite membrane with a microporous structure is obtained. Corona charging is then performed. The corona electrode is needle-shaped; the corona voltage is 32kV; there is no grid control voltage; the charging temperature is 25°C; the charging time is 60s; the distance between the corona electrode and the sample is 7cm. 100nm aluminum electrodes were vacuum-evaporated on both sides of the microporous membrane. A piezoelectric electret film is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com