PdP/C catalyst for high-performance direct methanoic acid fuel cell and producing method thereof

A formic acid fuel cell and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as loss of activity and difficulty in preparing Pd catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Take 10ml of water, add 31mgNaF and 125mgH 3 BO 3 , add 3.13ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Adjust the pH of the suspension with activated carbon to 8-9 with ammonia water.

[0037] Take 10ml of water, add 0.0228mmol NaH 2 PO 2 , the above PdCl 2 The suspension with activated carbon was slowly added dropwise to NaH 2 PO 2 In the aqueous solution, continue to sonicate for 1 hour, and stir in a 90°C water bath for 6 hours to make the PdCl 2 with reducing agent NaH 2 PO 2 Total response.

[0038] The impurity ions were removed by washing twice with water for several times, and the PdP / C powder catalyst with a Pd metal loading of 20% was obtained by drying at 60° C. under vacuum condition.

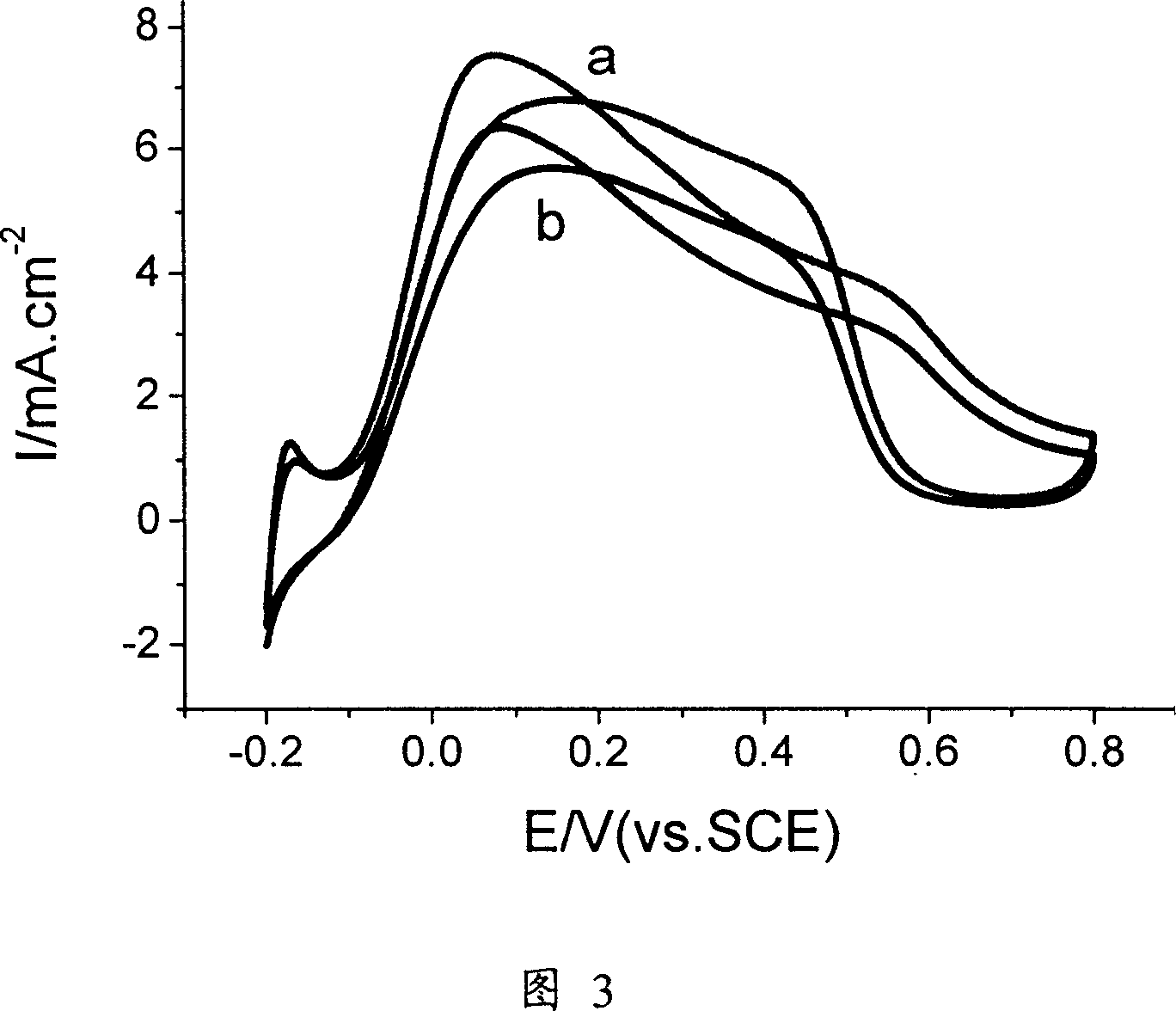

[0039] Referring to Figure 1 to Figure 4:

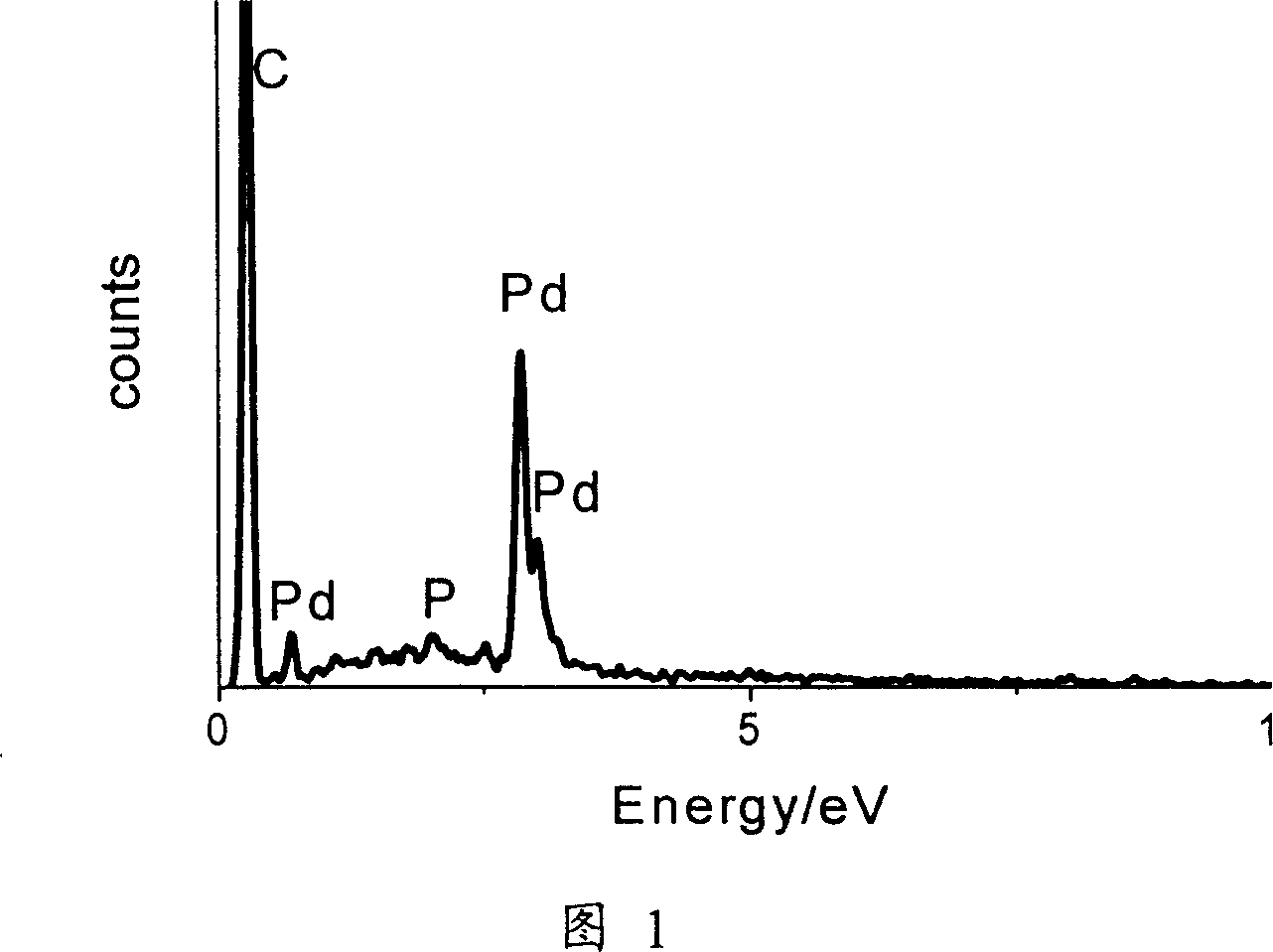

[0040] Figure 1: Energy dispersive spectrum (EDS) of 20% PdP / C catalyst;

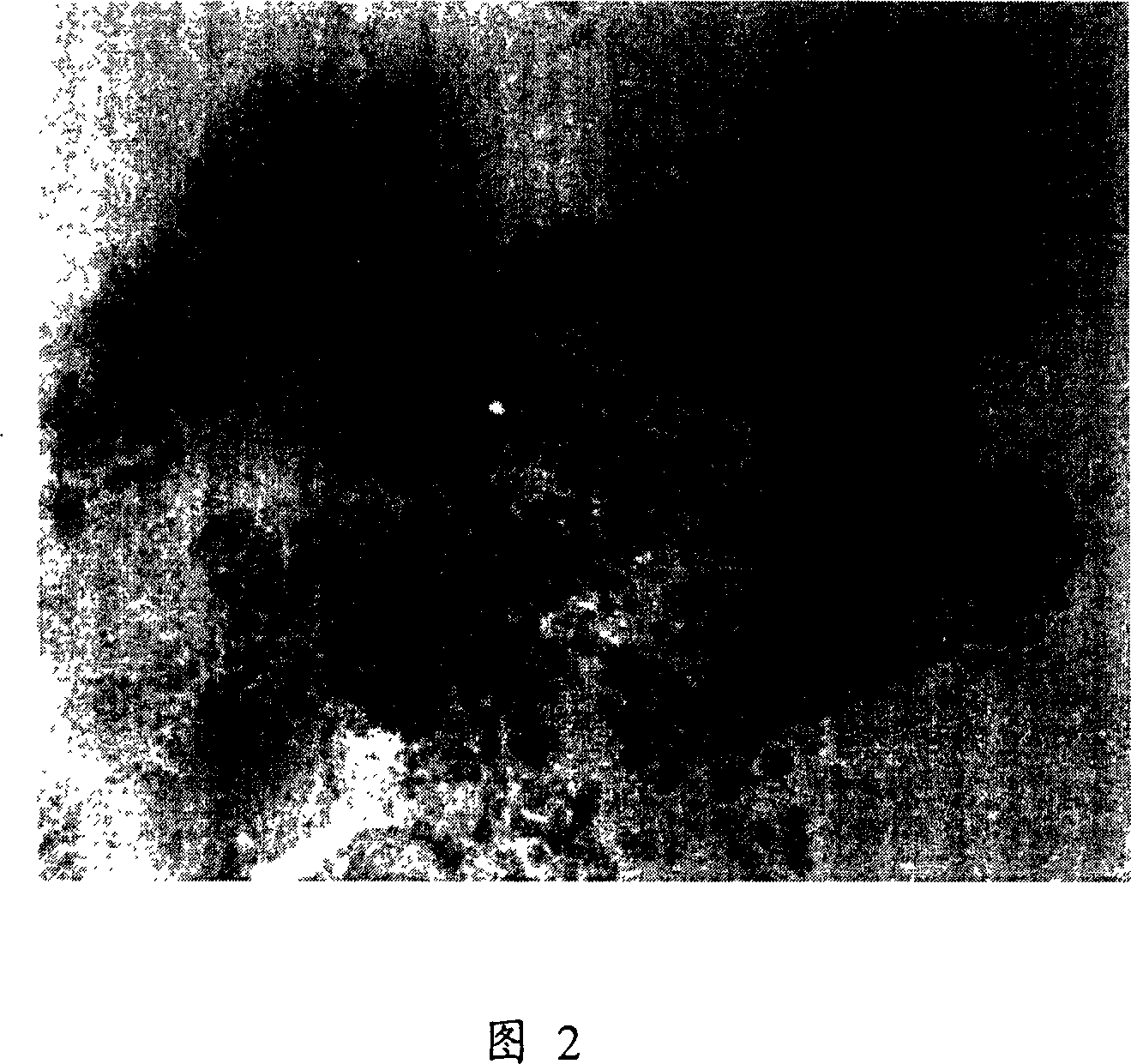

[0041] Figure 2: TEM photo of th...

Embodiment 2

[0045] 10ml water, add 25mg NH 4 F and 125 mg H 3 BO 3 , add 5.37ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Suspension with activated charcoal.

[0046] Take 10ml of water, add 2mmol NaH 2 PO 2 and 2 mmol H 3 PO 2 , the above PdCl 2 Slowly add the suspension with activated carbon into the reducing agent aqueous solution, continue to sonicate for 1 hour, and stir in a water bath at 90°C for 6 hours to make the PdCl 2 Reacts completely with reducing agents. After cooling to room temperature, wash with suction and wash with water twice to remove impurity ions. 2 The PdP / C powder catalyst with a Pd metal loading of 30% was obtained by drying at 60°C under air protection.

Embodiment 3

[0048] 10ml water, add 44mg KF and 125mg H 3 BO 3 , add 8.37ml 0.04504molL -1 PdCl 2 After ultrasonication for 10 minutes, add 60 mg of activated carbon and continue ultrasonication for 30 minutes to obtain PdCl 2 Suspension with activated charcoal.

[0049] Take 10ml of water, add 3mmol NaH 2 PO 2 , 3 mmol H 3 PO 2 , 3mmol KH 2 PO 2 , the above PdCl 2 Slowly add the suspension with activated carbon into the reducing agent aqueous solution, continue to sonicate for 1 hour, and stir in a water bath at 90°C for 6 hours to make the PdCl 2 Reacts completely with reducing agents. After cooling to room temperature, it was filtered and washed, washed twice with water to remove impurity ions, and dried at 60°C under vacuum to obtain a PdP / C powder catalyst with a Pd metal loading of 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com