Method for treating oily odour gas

A technology of malodorous gas and treatment method, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of poor oil-containing exhaust gas, complex oil-containing exhaust gas composition, and oil-containing exhaust gas discharge, etc., and achieves good pressure resistance. , High hardness and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

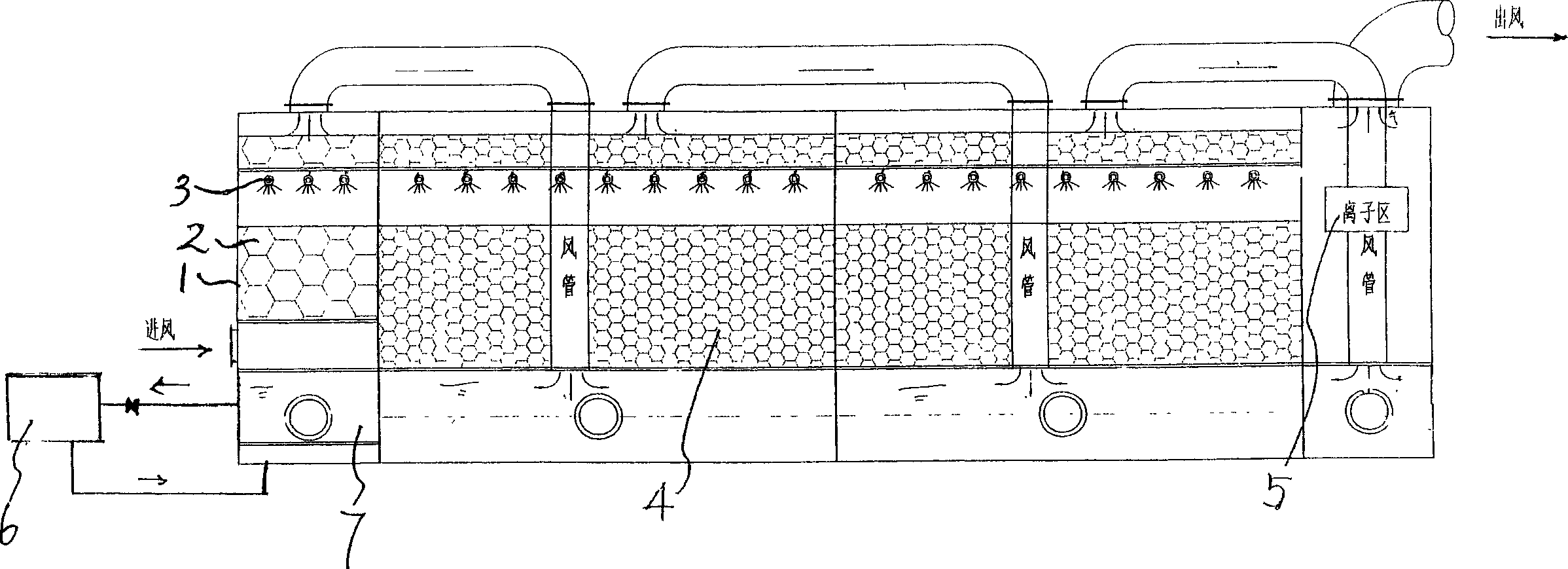

[0013] A treatment method for oil-containing malodorous gas, comprising the following steps:

[0014] (1) oily waste gas is passed through the walnut shell packing layer 2 in the container 1, and sprayed through the atomizing spraying device 3 above the walnut shell packing layer 2;

[0015] (2) passing the waste gas treated in step (1) through the biological filler 4, and spraying treatment through the spray device above the biological filler 4;

[0016] (3) The exhaust gas treated in step (2) is treated by ion oxygen treatment device 5 .

[0017] In the circulating water tank 7, the oil-water mixture obtained by spraying the waste gas is subjected to the oil-water separation process through the oil-water separator 6, and the oil is separated, and the water can be returned to the circulating water tank 7 for reuse. Due to the effect of spraying circulating water, the walnut shells are continuously washed and washed, so as to ensure that the walnut shells can be used repeated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com