Method and apparatus for separating acetyl methamidophos from neutral solution

A technology of acephate and extractant, which is applied in the field of separation of acephate, can solve the problems of high energy consumption, clogging of extractor, large operating current of motor, etc., and achieve low energy consumption, high processing efficiency and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

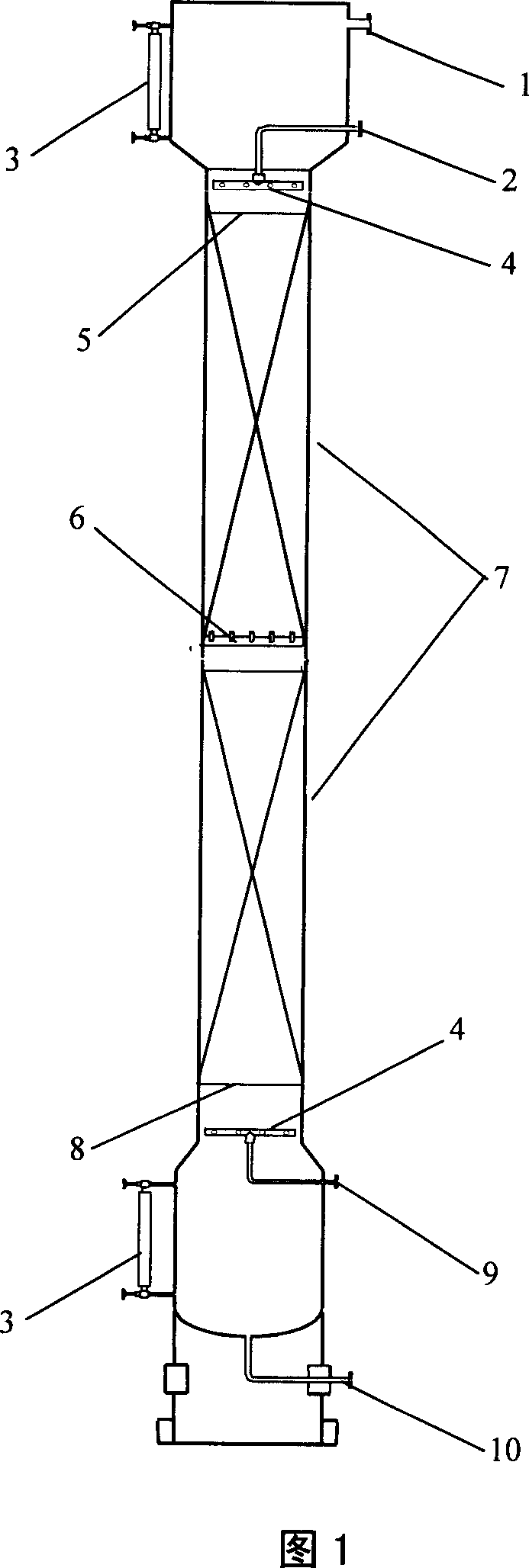

[0017] The invention provides a method and a device for separating acephate from a neutralization solution. Fig. 1 is a schematic diagram of the structure of a packing extraction tower. The device for separating acephate from the neutralization liquid shown in the figure is a kind of efficient packing extraction tower with a reasonable structure to replace the original centrifugal extraction equipment. It is limited by the tower body, packing and packing It is composed of bit plate, packing support plate, liquid distributor and redistributor. There are liquid level controller 3 and raffinate phase outlet 1 at the top of the tower body, liquid level controller 3 and extract phase outlet 10 at the bottom, extractant inlet 2 above the packing limit plate 5 of the tower body, and tower body packing support plate There is a neutralizing liquid inlet 9 below the 8, and a filler 7 is installed between the filler limiting plate and the filler support plate. The height of each layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com