Liquid-cooled radiating system

A cooling system, liquid cooling technology, applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve the problems of wasting energy, unable to achieve timely, high-efficiency heat exchange, burning computer chips, etc., to save energy The effect of electric energy, energy saving and component loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Generally, when there is a temperature difference between opposite end surfaces of a thermoelectric material, an electromotive force E is generated between the two end surfaces. This is the Siberk effect. The electromotive force generated due to the Siberk effect is called thermoelectric electromotive force. If the thermoelectric material is made into a thermoelectric converter and placed in a loop, when there is a temperature difference between the opposite ends of the thermoelectric converter, a current will be generated at the electrical output of the thermoelectric converter, and the current will flow along the loop. back to the electrical input of the thermoelectric converter, thereby forming an electrical loop.

[0011] Below, the present invention will be further described in detail in conjunction with the accompanying drawings.

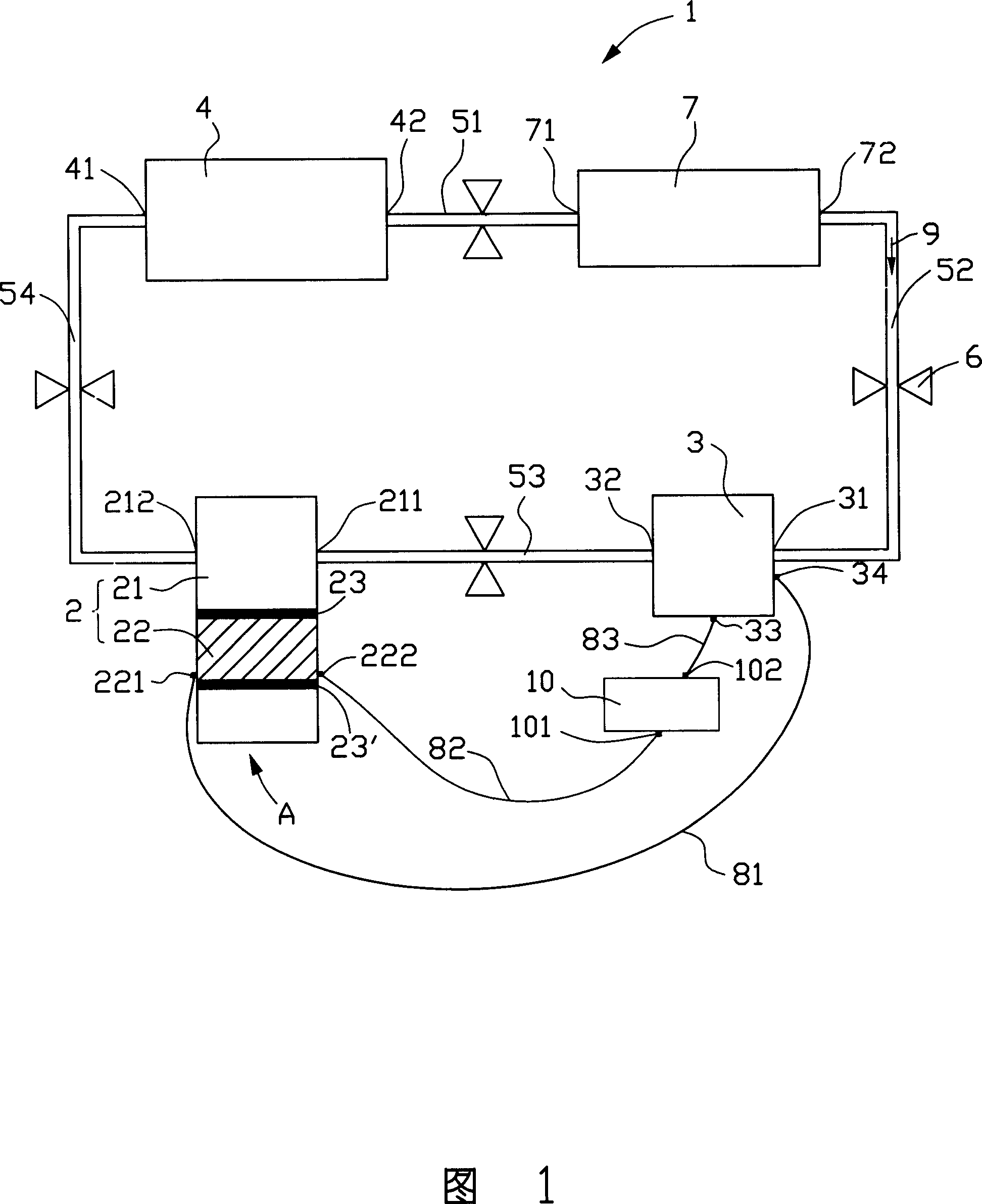

[0012] Referring to Fig. 1, a liquid-cooled heat dissipation system 1 of a preferred embodiment of the present invention includes: a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com