Apparatus for controlling temperature of an inline measuring device

A technology for heat exchangers and measuring instruments, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

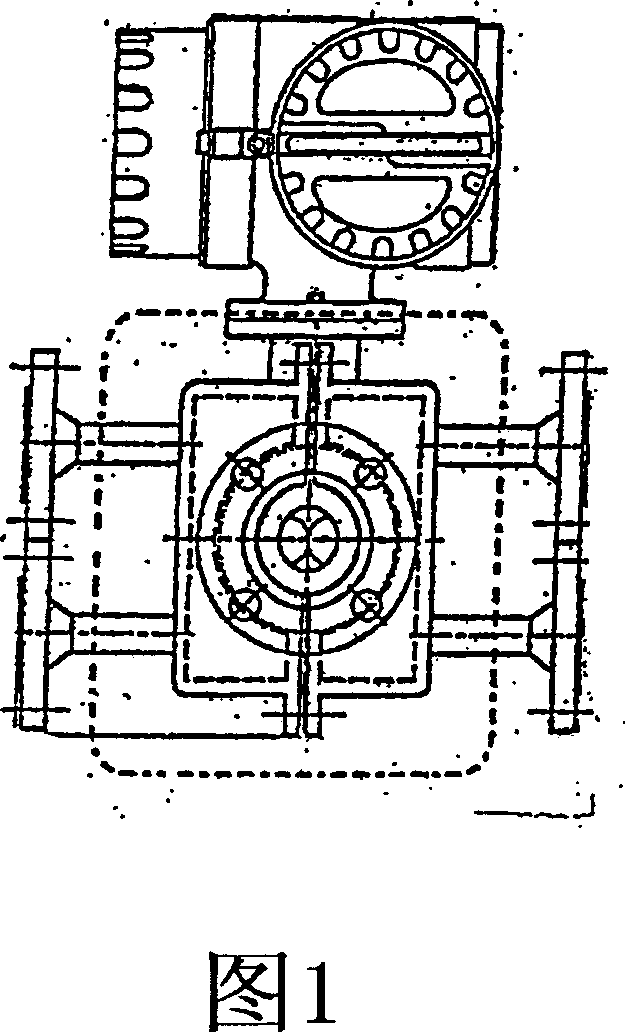

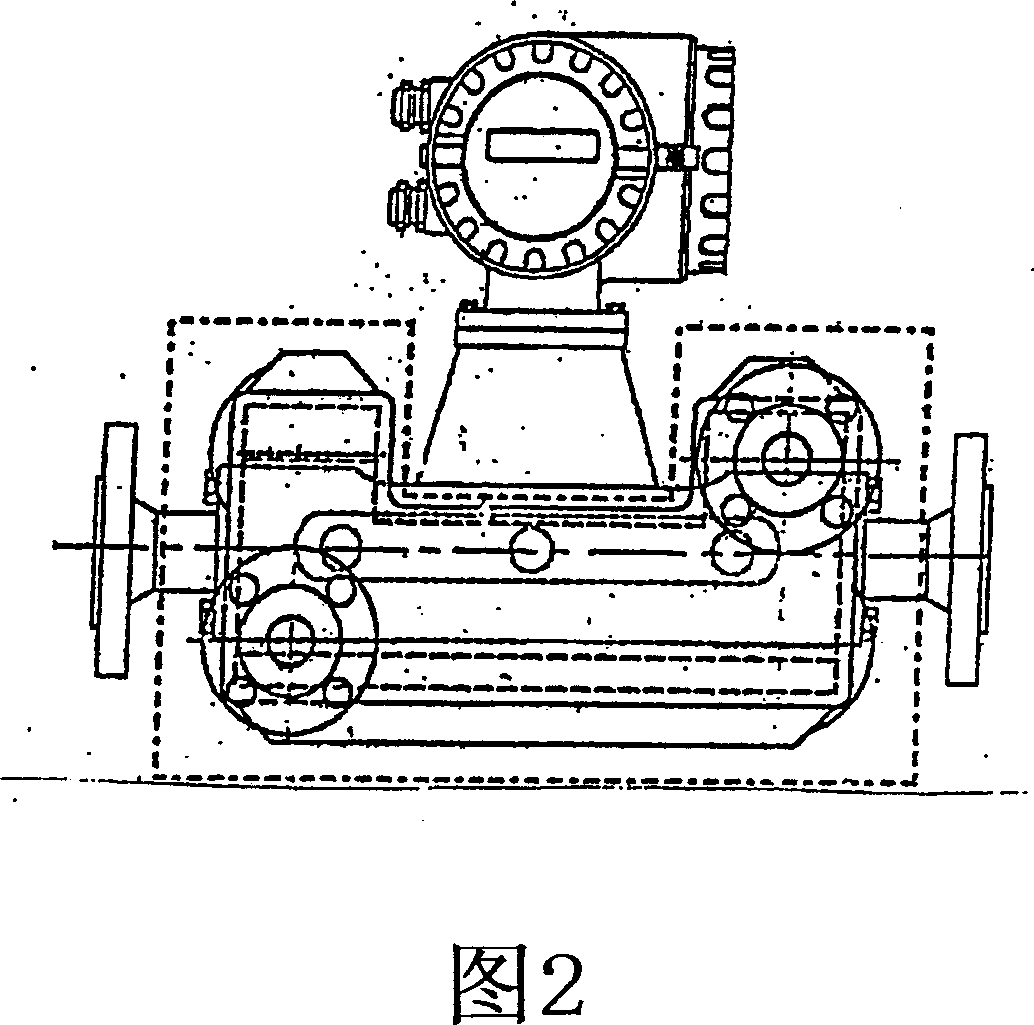

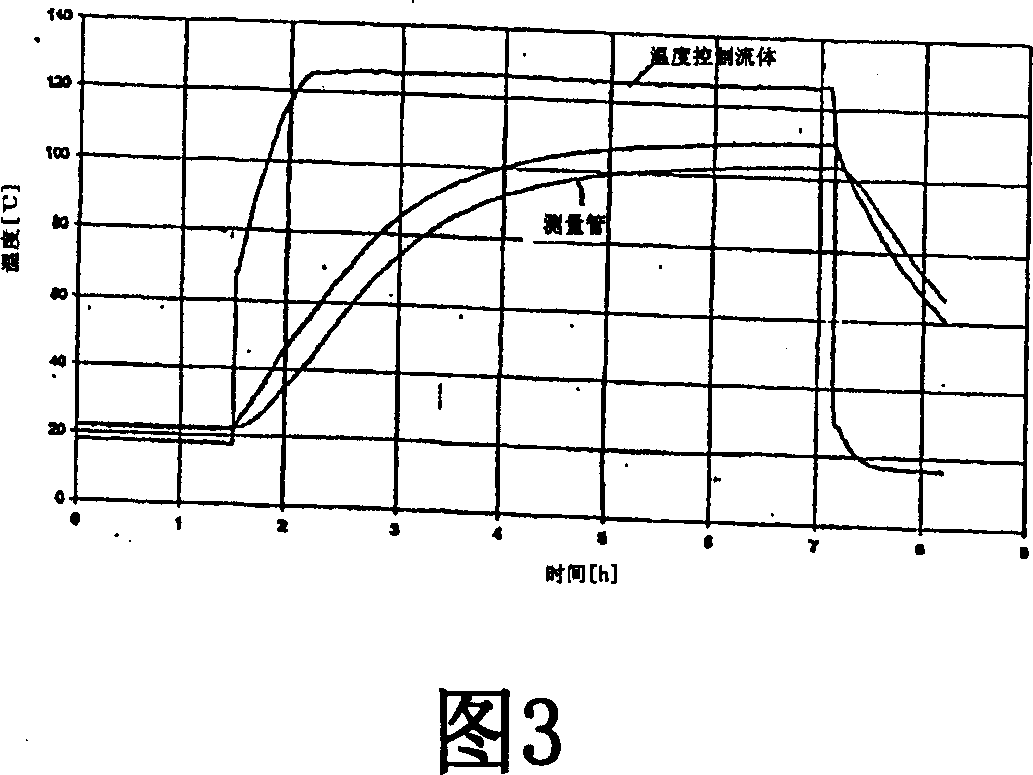

[0069] 5 and 6 show a device for temperature control of a process measuring device 1 implemented as an in-line measuring device. The process measuring device 1 is used to detect at least one, in particular physical, measured variable, such as mass flow, density and / or viscosity, of a medium guided in a pipeline and to map it into a measured value signal that instantaneously represents this measured variable; not shown here out of the pipe. An example of an on-line measuring instrument utilizes a vibration-type measuring transducer 10 preferably housed in the measuring transducer housing 7, 6 and utilizes a The measuring device electronics 20 detects the measured variable. The device serves to maintain the temperature of the on-line measuring instrument and thus also the temperature of the medium conducted through the on-line measuring instrument within a predetermined temperature range.

[0070] For guiding the medium, such measuring transducers comprise at least one measuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com