Stepless speed regulating well repairing device

A technology for stepless speed regulation and workover, which is applied in drilling equipment, drilling equipment and methods, and earth-moving drilling, etc., can solve the problems of complex structure of workover rig, large braking torque, frequent clutch clutch, etc. The effect of reducing equipment maintenance, small braking torque and reducing operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

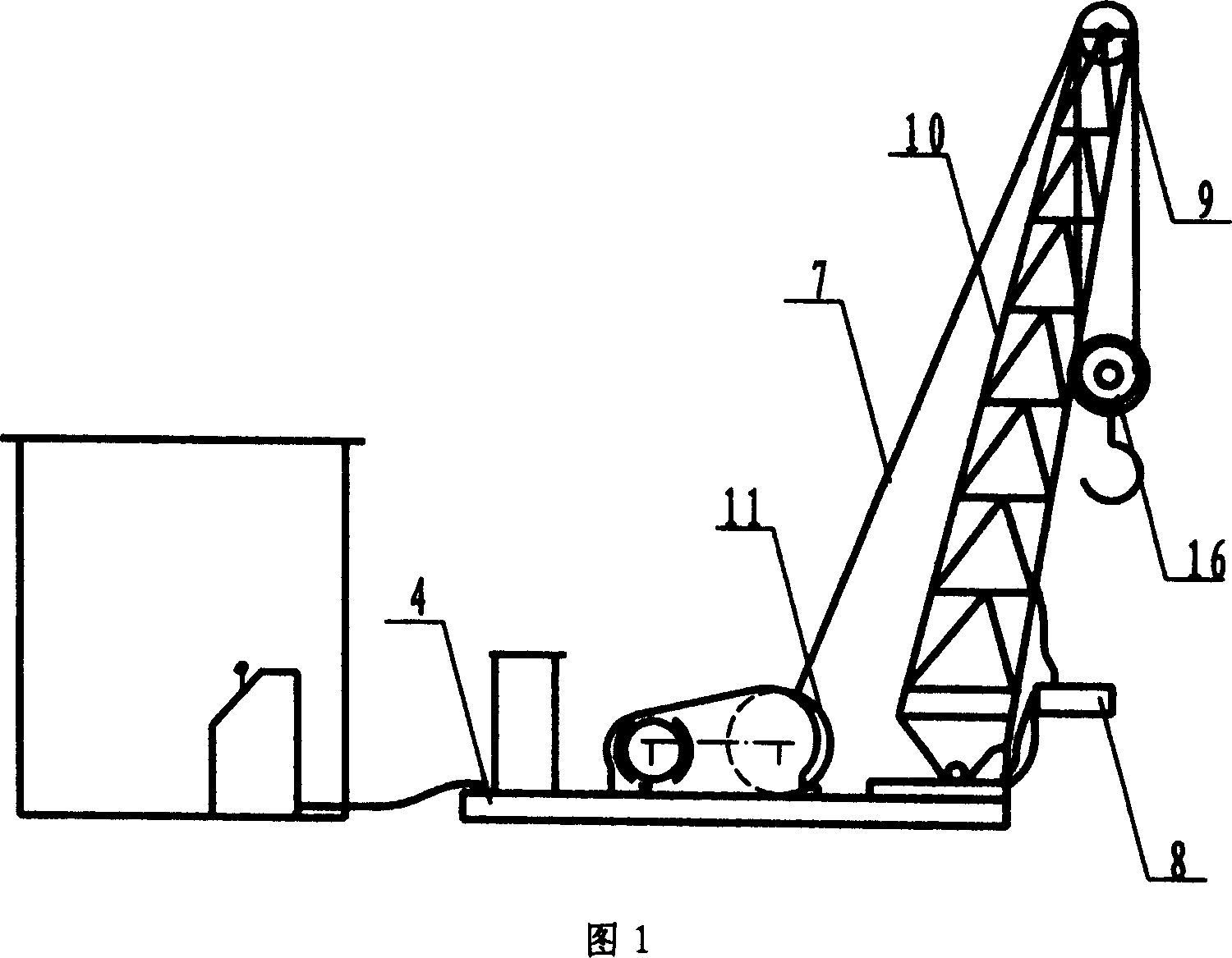

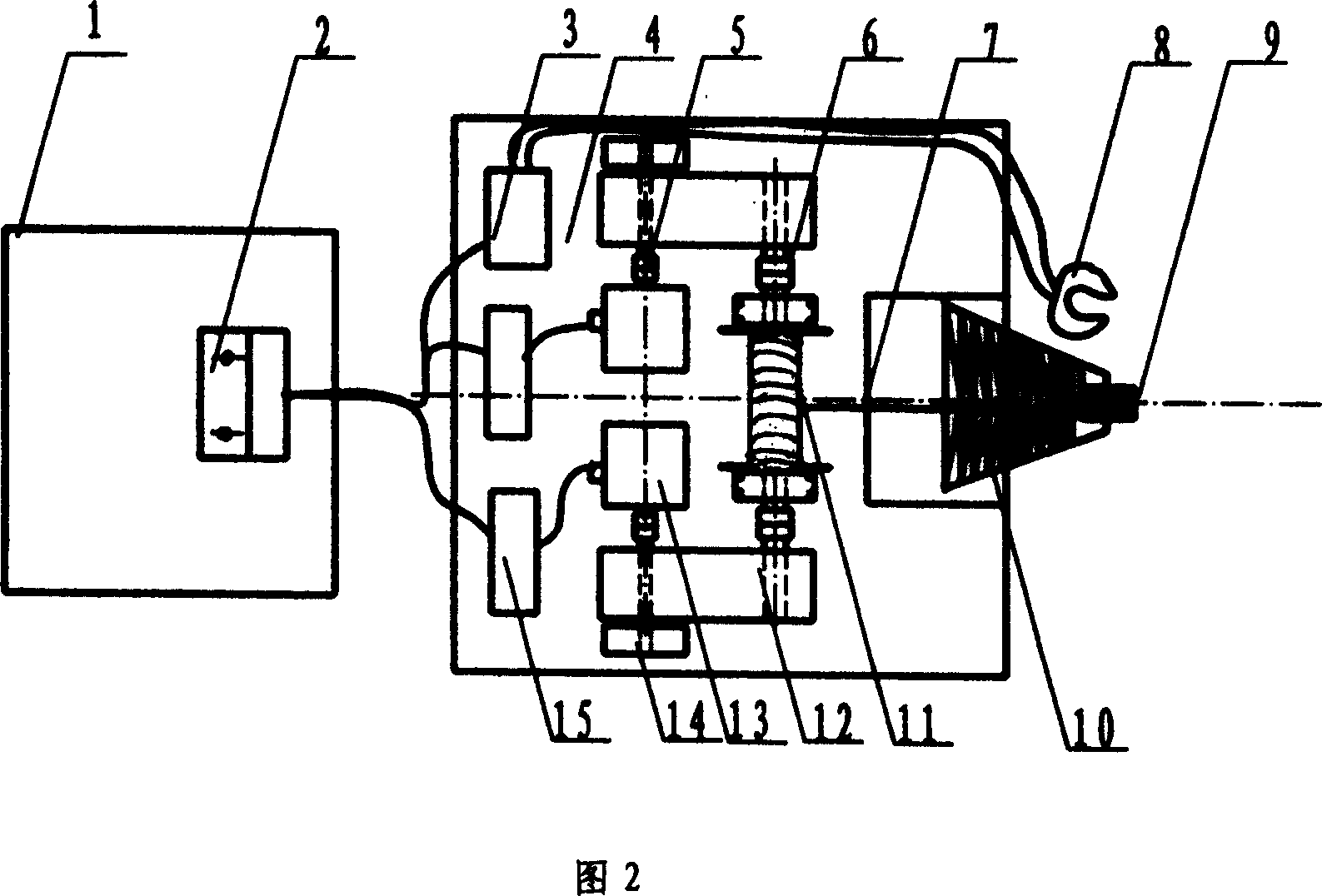

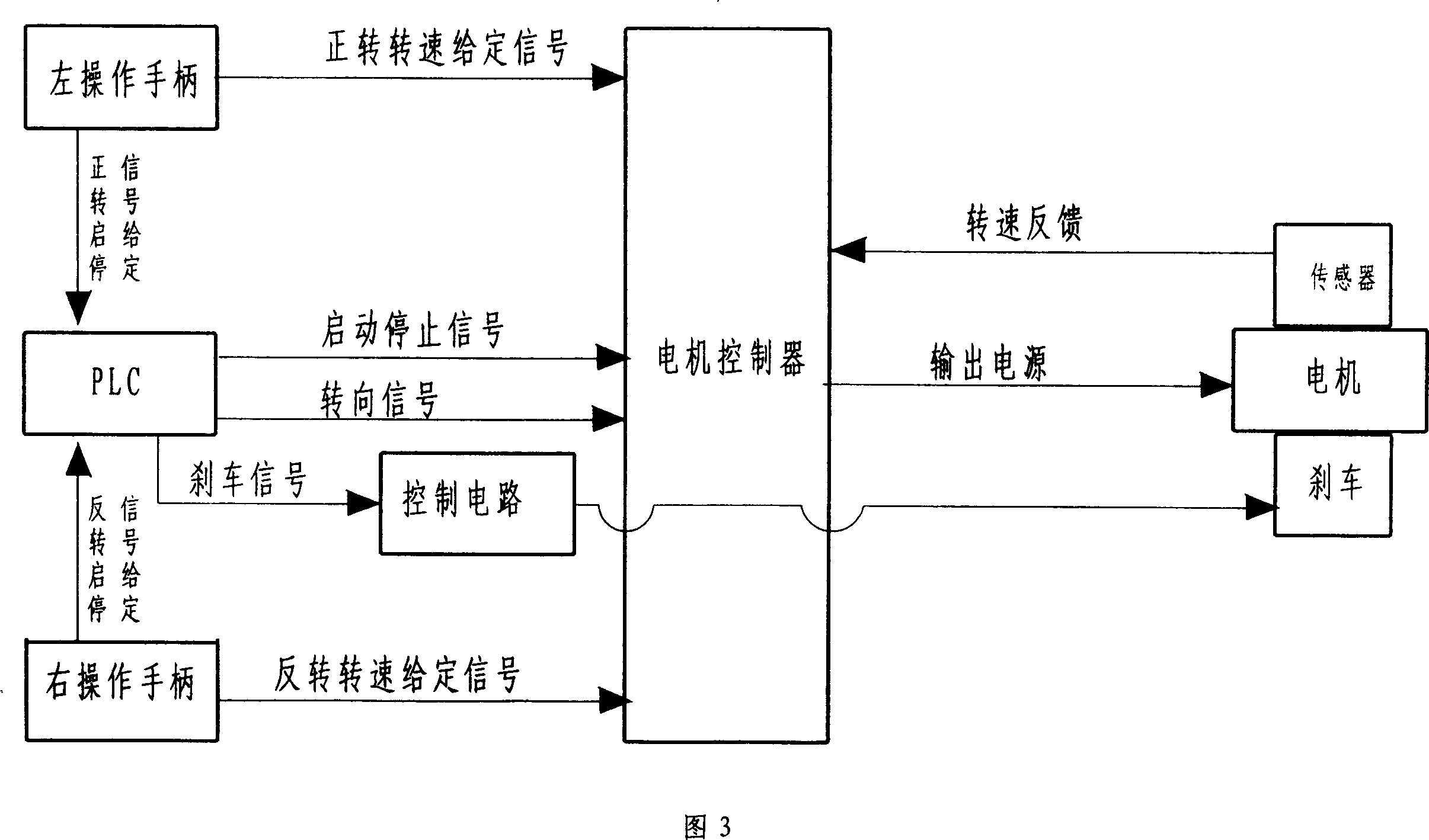

[0019] A stepless speed regulation workover device, as shown in Figure 2, consists of an operating room 1, a console 2, a hydraulic mechanism 3, a base 4, a motor coupling 5, a drum coupling 6, a wire rope 7, and a hydraulic clamp 8 , crown block 9, frame 10, drum 11, transmission 12, motor 13, brake brake 14, control cabinet 15, traveling block and hook 16, is characterized in that the base 4 is set as a rectangle, and the middle part of the base is horizontally arranged The drum 11, the motor 13 and the transmissions 12 on both sides; the frame 10 is fixed in the front middle of the base, the hydraulic mechanism 3 and the control cabinet 15 are installed in the rear of the base; the operating room 1 and the indoor console 2 are arranged in the middle of the rear of the base; The two ends of the drum are connected with the output shaft of the transmission 12 with the drum coupling 6, the motor shaft is connected with the input shaft of the transmission with the motor coupling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com