Embedding method for printed circuit board and printed circuit board

A printed circuit board, the first technology, applied in the direction of printed circuit, printed circuit manufacturing, printed circuit assembly of electrical components, etc., can solve the problems of unfavorable promotion and application, high production cost, expensive price, etc., to improve flexibility, The effect of saving process and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

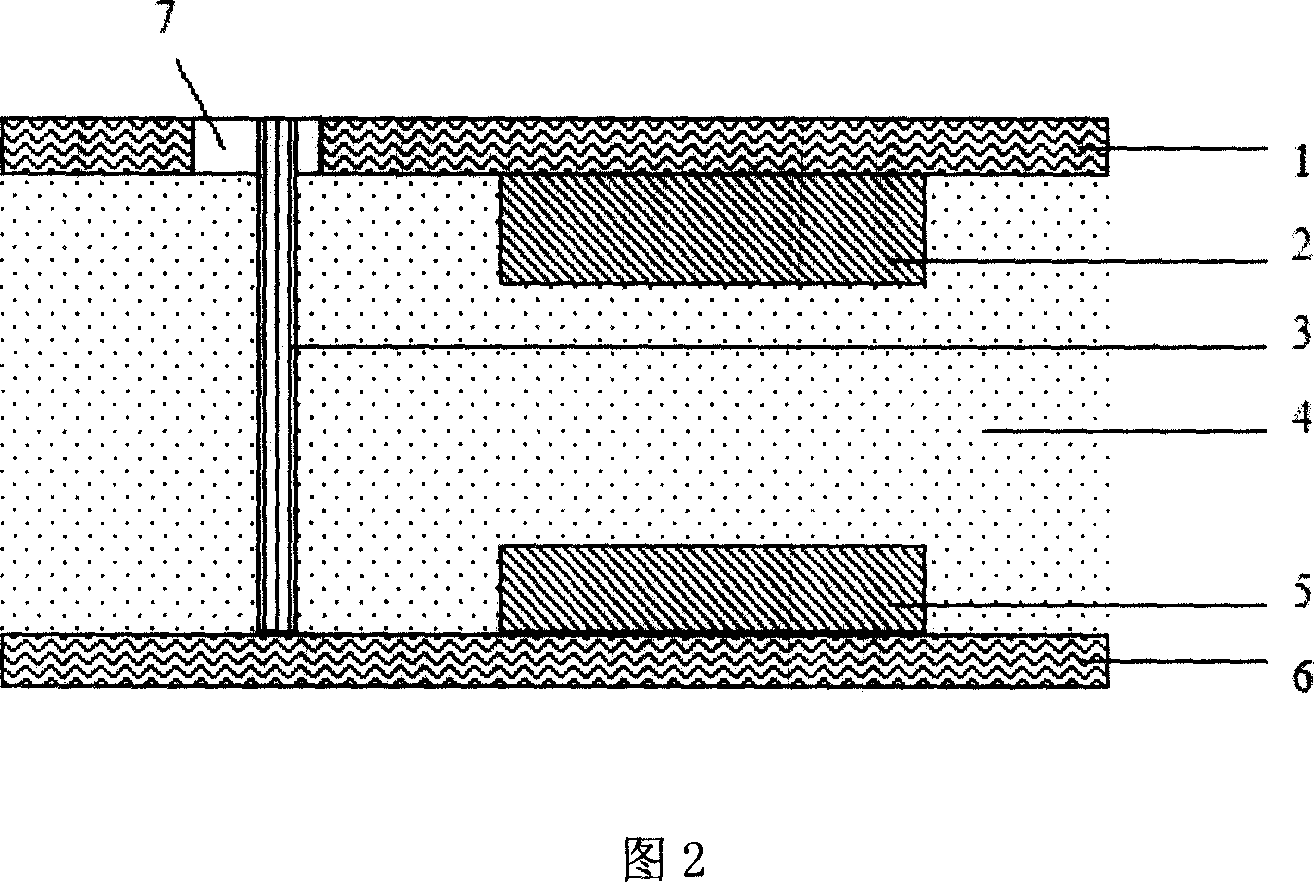

[0023] The present invention is further elaborated below in conjunction with accompanying drawing and embodiment:

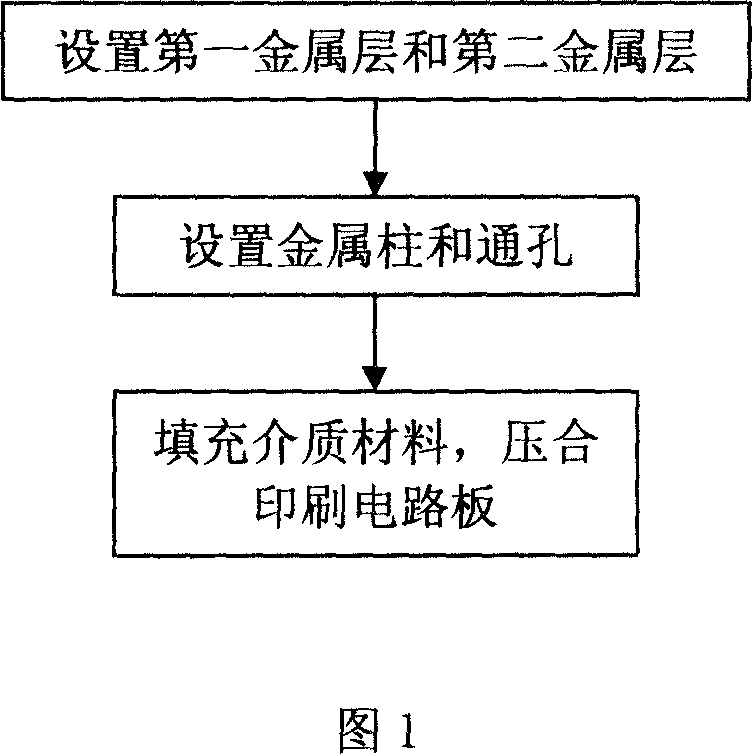

[0024] Refer to FIG. 1 for the flow chart of the method for embedding capacitance on a PCB in the present invention. The present invention can be embedded in any position on the PCB, and the specific process is as follows:

[0025] The first step: by means of electroplating or etching, a first metal layer is provided on the first surface of the power supply layer to increase the thickness of the metal, and a second metal layer is provided on a corresponding area on the first surface of the ground layer parallel to the power supply layer to Increase the metal thickness in this area; thereby reducing the distance between the power supply layer and the ground layer in this area, which is conducive to the formation of plate capacitance; wherein, the corresponding area is located on the first surface of the ground layer with an area opposite to the first metal layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com