Method of preparing low impurity content, clear and transparent food grade lecithin and product

A kind of lecithin, low impurity technology, applied in the field of separation and purification of food additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

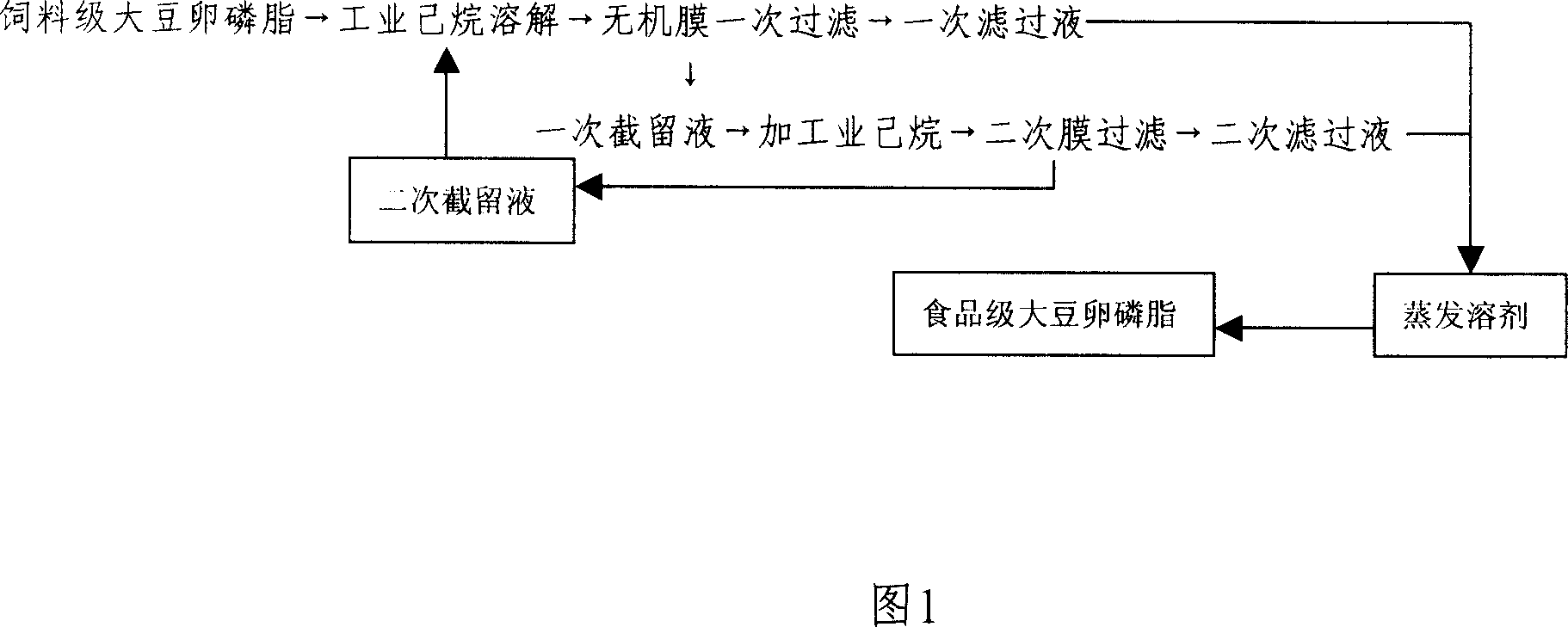

Method used

Image

Examples

Embodiment 1

[0054] Take 3kg of feed grade soybean lecithin, add 12 liters of industrial hexane according to the weight to volume ratio, filter with a 0.2 μm membrane at 50°C and a filtration pressure of 0.15Mpa, and concentrate to 1.2 liters. An additional 3.6 liters of solvent was added to the concentrate, and the concentration was continued to 2 liters. The two filtrates were combined, and the solvent was evaporated to obtain the product of the present invention.

Embodiment 2

[0056] Get 3kg of feed grade soybean lecithin, add 9 liters of industrial hexane to dissolve, and make a solution. Filtrate with a 0.1 μm membrane at 50° C. and a filtration pressure of 0.15 MPa, and concentrate to 1 liter. The obtained filtrate is subjected to rotary evaporation to obtain filtered lecithin.

Embodiment 3

[0058] Get 3kg of feed grade soybean lecithin, add 21 liters of industrial hexane to dissolve, and make a solution. Filtrate with a 0.6 μm membrane at 50° C. and a filtration pressure of 0.15 MPa, and concentrate to 3 liters. The obtained filtrate is subjected to rotary evaporation to obtain filtered lecithin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com