Laser welding system

A technology of laser welding and laser emission system, applied in the field of systems using laser welding workpieces, can solve the problems of uneven welding, heat can not be removed in time, affecting the appearance of products, etc., to avoid uneven heating and smooth welding surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The laser welding system will be further described in detail with reference to the accompanying drawings and embodiments.

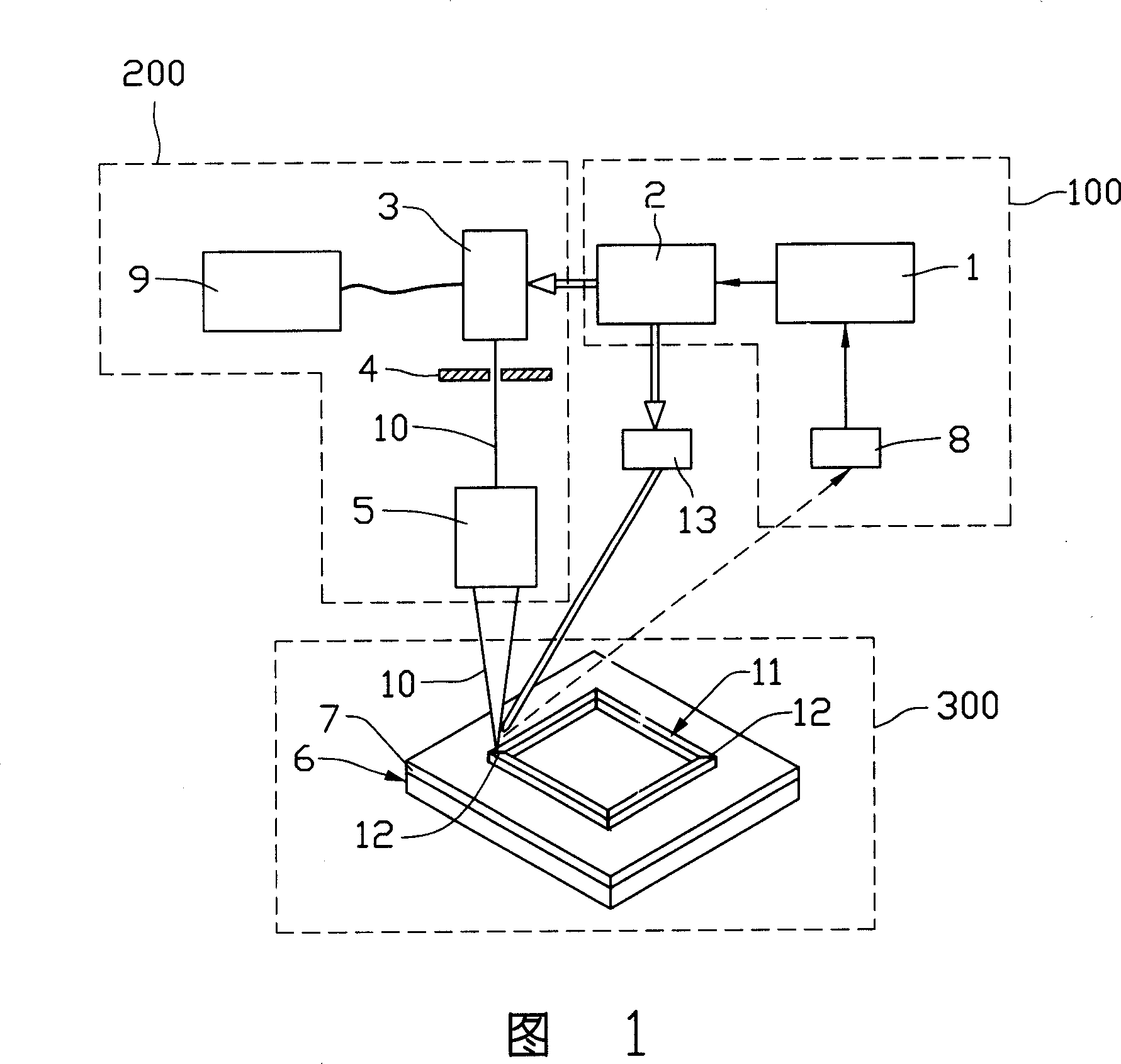

[0013] Please see FIG. 1 , which is a schematic diagram of a laser welding system according to an embodiment of the present invention, which includes: a control system 100 , a laser emitting system 200 and a receiving system 300 . The control system 100 is connected with the laser emitting system 200 to control (the double straight arrow in the figure represents control) the laser emitting system 200 emits the laser light 10 and irradiates the receiving system 300, and the control system 100 is used for detection (dashed straight arrow means detection), process the information from the receiving system 300, and further adjust and control the laser emitting system 200 to emit the laser light 10 according to the information, forming a closed-circuit system, wherein the receiving system 300 includes a support frame 6 supporting the welding workpiece 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap