Acetylene selected hydrogenation catalyst and its preparation method

A technology of selective hydrogenation and catalyst, applied in the field of simple palladium catalyst and its preparation, can solve the problems of strict equipment requirements, achieve the effect of improving utilization rate, increasing selectivity and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

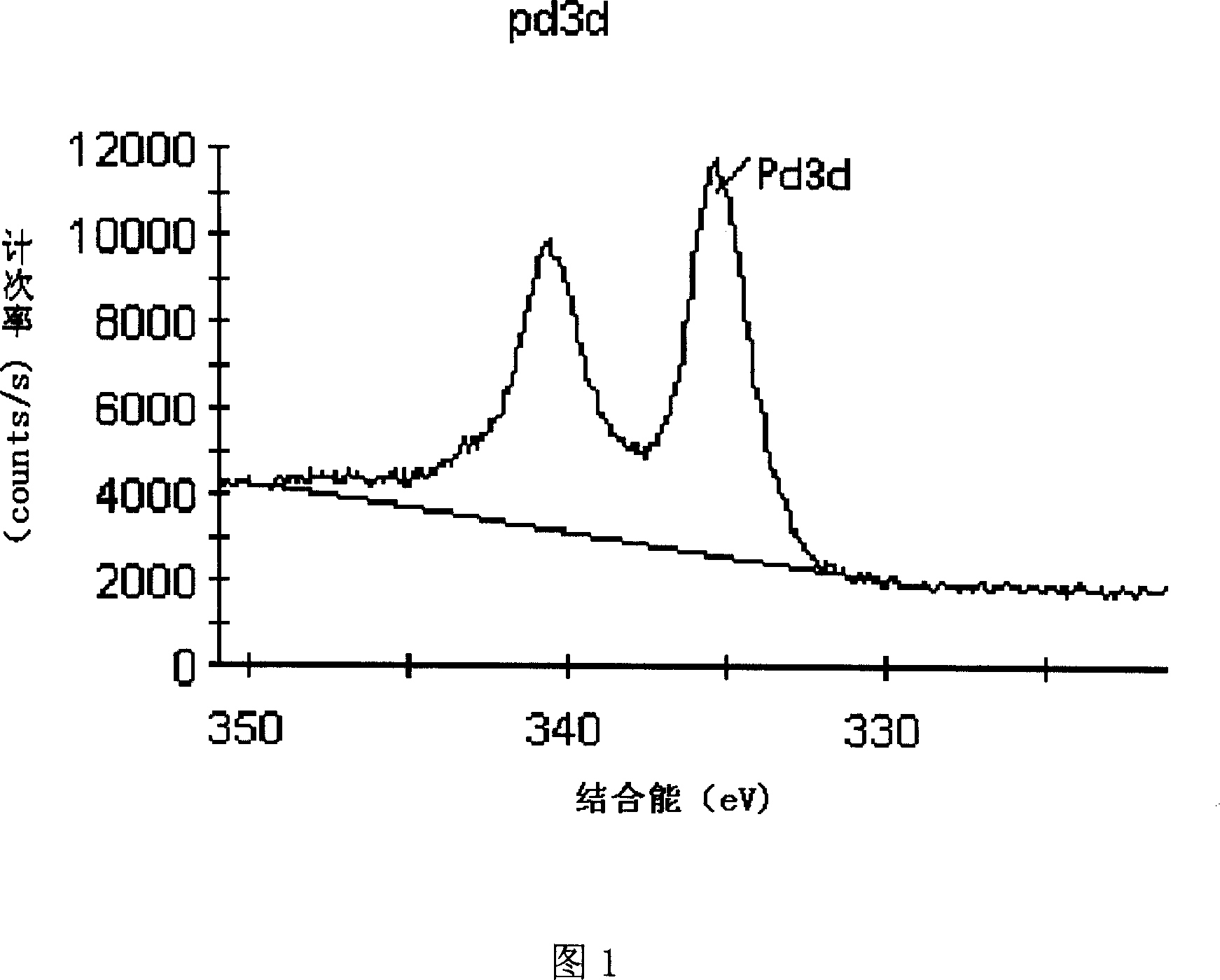

Method used

Image

Examples

Embodiment 1

[0050] Weigh 50g spherical Al 2 o 3 Add the carrier to 50ml of 3g / L SnCl 2 Sensitize in the sensitization solution, and then add the carrier to 50ml of 0.01g / L PdCl 2 activated in an acidic solution, the removed carrier was washed with distilled water, and the above steps were repeated 5 times. After sensitization and activation, the carrier contains 0.0035 g of palladium.

[0051] Add the activated carrier to 2.5g / L [Pd(NH 3 ) 2+ ] in the palladium plating solution, the total amount of Pd in the plating solution is 0.0175g, under the condition of 45 ℃, add reducing agent hydrazine 2ml, stir, electroless plating 10min, after plating, rinse the solution with deionized water until there is no Cl - . Finally, under the condition of 105°C, dry for 18 hours to obtain the catalyst A, wherein the Pd content is 0.035% (wt), and the Sn content is 0.7% (wt).

Embodiment 2

[0053] Weigh 50g of extruded strip Al 2 o 3 Add the carrier to 40ml of 11g / L SnCl 2 Sensitize in the sensitization solution, then add the carrier to 80ml of 0.05g / L PdCl 2 activated in an acidic solution, the removed carrier was washed with distilled water, and the above steps were repeated 6 times. After sensitization and activation, the carrier contains 0.012g of palladium.

[0054] Add the activated carrier to 0.5g / L [Pd(NH 3 ) 2+ ] in the palladium plating solution, the total amount of Pd in the plating solution is 0.0055g, under the condition of 40 ℃, add reducing agent hydrazine 2ml, stir, electroless plating 5min, after plating, rinse the solution with deionized water until there is no Cl - . Finally, under the condition of 120°C, dry for 10 hours to obtain the catalyst B, wherein the Pd content is 0.035% (wt), and the Sn content is 2.7% (wt).

Embodiment 3

[0056] Weigh 50g tooth type Al 2 o 3 Add the carrier to 100ml of 5g / L SnCl 2 Sensitize in the sensitization solution, and then add the carrier to 100ml of 0.1g / L PdCl 2 activated in an acidic solution, the removed carrier was washed with distilled water, and the above steps were repeated 3 times. After sensitization and activation, the carrier contains 0.02 g of palladium.

[0057] Add the activated carrier to 3g / L [Pd(NH 3 ) 2+ ] in the palladium plating solution, the total amount of Pd in the plating solution is 0.015g, and at 75°C, the reducing agent NaH 2 PO 2 0.10g, stirring, electroless plating for 20min, after plating, rinse the solution with deionized water until there is no Cl in the washing solution - . Finally, under the condition of 120°C, dry for 5 hours to obtain the catalyst C, wherein the Pd content is 0.05% (wt), and the Sn content is 1.5% (wt).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap