Composite board of wood and plastic produced from stalk of crop

A technology for composite boards and crops, which is applied in the joining of wooden veneers, wood-layered products, and wood processing appliances, etc., can solve the problems that the impact resistance strength cannot reach the level of wooden boards and wood-based boards, and can achieve Wide supply of raw materials, high economic benefits, and the effect of enhancing physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

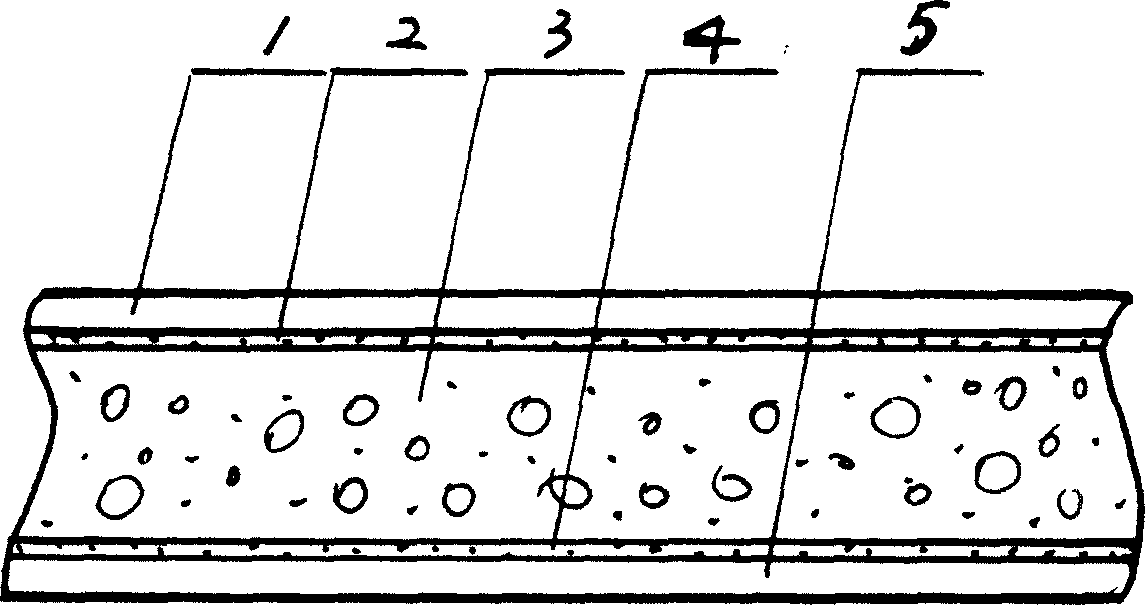

[0009] Embodiment 1, in the figure, straw plate core (3) is straw artificial board, and drying time is: 7 minutes, and its moisture content is: 7%; Its veneer glue (2), (4) select E for use 1 Grade special-purpose MVF glue, using a spiral sizing machine, the pressure of its veneer is: 12.3MPa, the thickness of its veneered straw veneer (1), (5) is: 2mm wooden board, its veneer is double Noodle type, using hot pressing method, hot pressing temperature: 165°C, time: 7 minutes.

Embodiment 2

[0010] Example 2, in the figure, the straw board core (3) is a straw wood-based board, the drying temperature of the straw board core (3) is: 175°C temperature, the drying rate is: 8≤%, and the drying time is 7 Minutes, its veneer glue (2), (4) selects high-grade latex for use, and the sizing machine selects the spiral sizing machine for use, and the pressure of its veneer is: 12.3PMa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com