Power generation by backheat, waste heat in single voltage and low parameters

A waste heat power generation and parameter technology, which is applied in the direction of preheating, steam generation, and steam generation devices, can solve the problems of poor stability and reliability of the waste heat power generation system, low comprehensive utilization rate of exhaust gas waste heat, and small adaptability range of waste gas waste heat fluctuations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

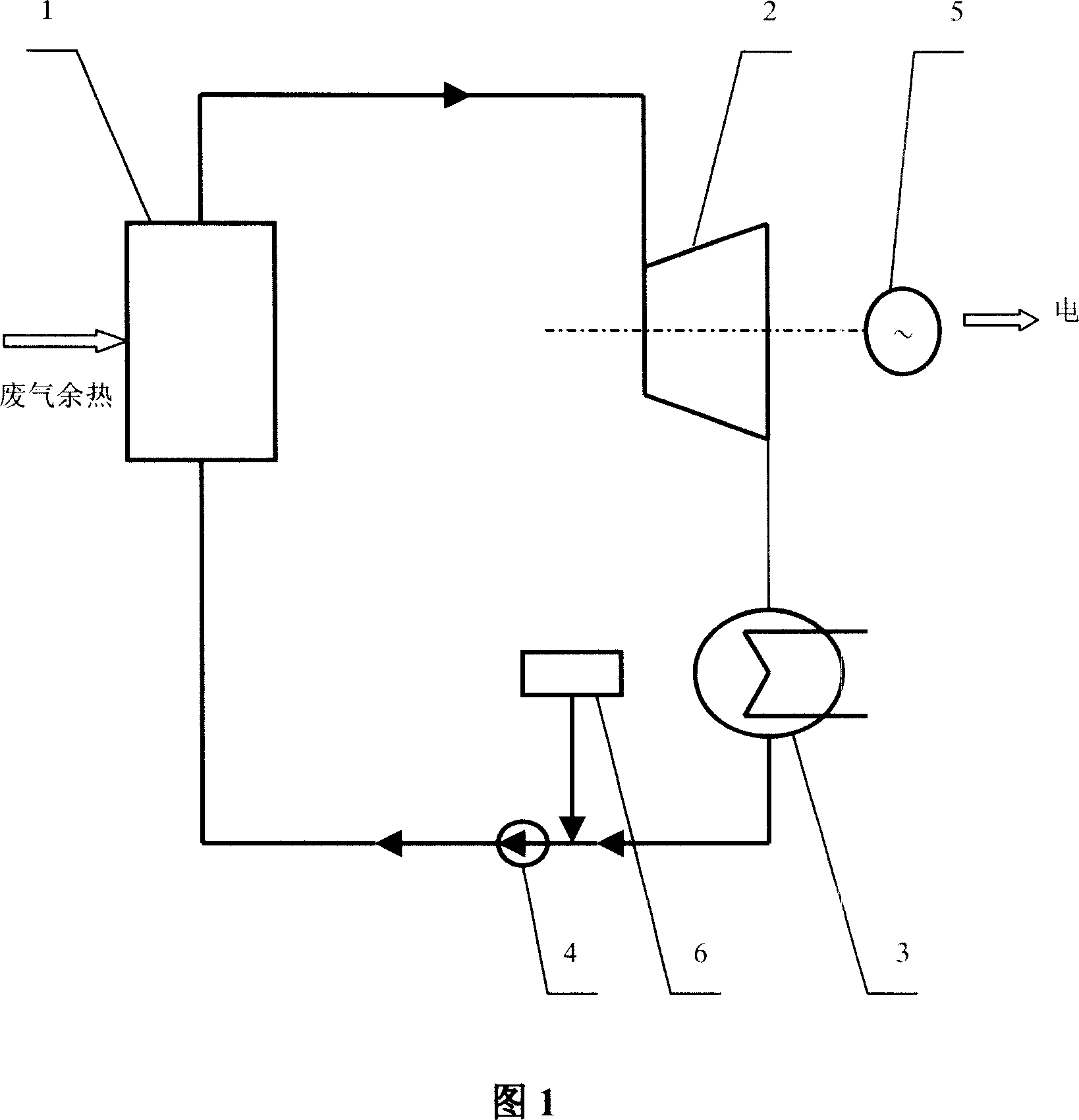

[0013] In Fig. 1, the existing waste heat power generation system includes a waste heat boiler 1, a steam turbine 2, a generator 5, a condenser 3, a feed water pump 4 and a water supply system 6, and the equipments are connected by pipelines, and the steam turbine 2 drives the generator 5 Power generation, the heat source comes from the waste gas heat source in various industrial processes, and the heat energy in the waste gas heat source is realized through the process of "exhaust gas heat energy----working medium heat energy----mechanical energy----electric energy" through the waste heat boiler The conversion of waste heat resources is also an energy conversion process.

[0014] Specifically, the waste heat boiler 1 heats the waste gas heat energy into water vapor, and the water vapor drives the steam turbine 2 to rotate, and the steam turbine 2 drives the generator to generate electricity. Transported to the waste heat boiler, this is a basic steam power cycle process, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com