Feeding mechanism of powder molding press

A technology of feeding mechanism and compression molding machine, applied in the field of feeding mechanism of powder compression molding machine and powder compression molding machine, can solve the problems of low stability of use, complex structure, too many parts, etc. Uniform and high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

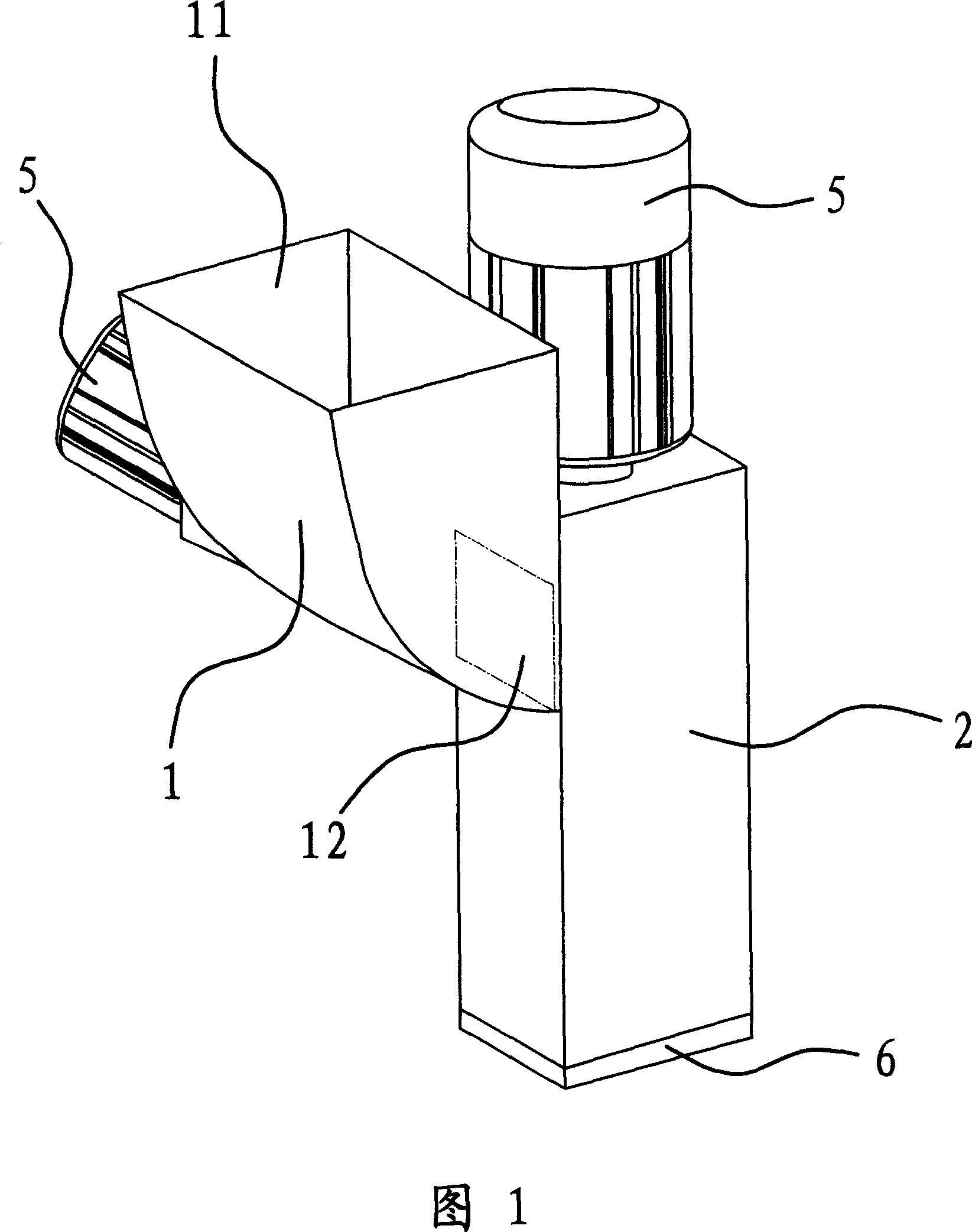

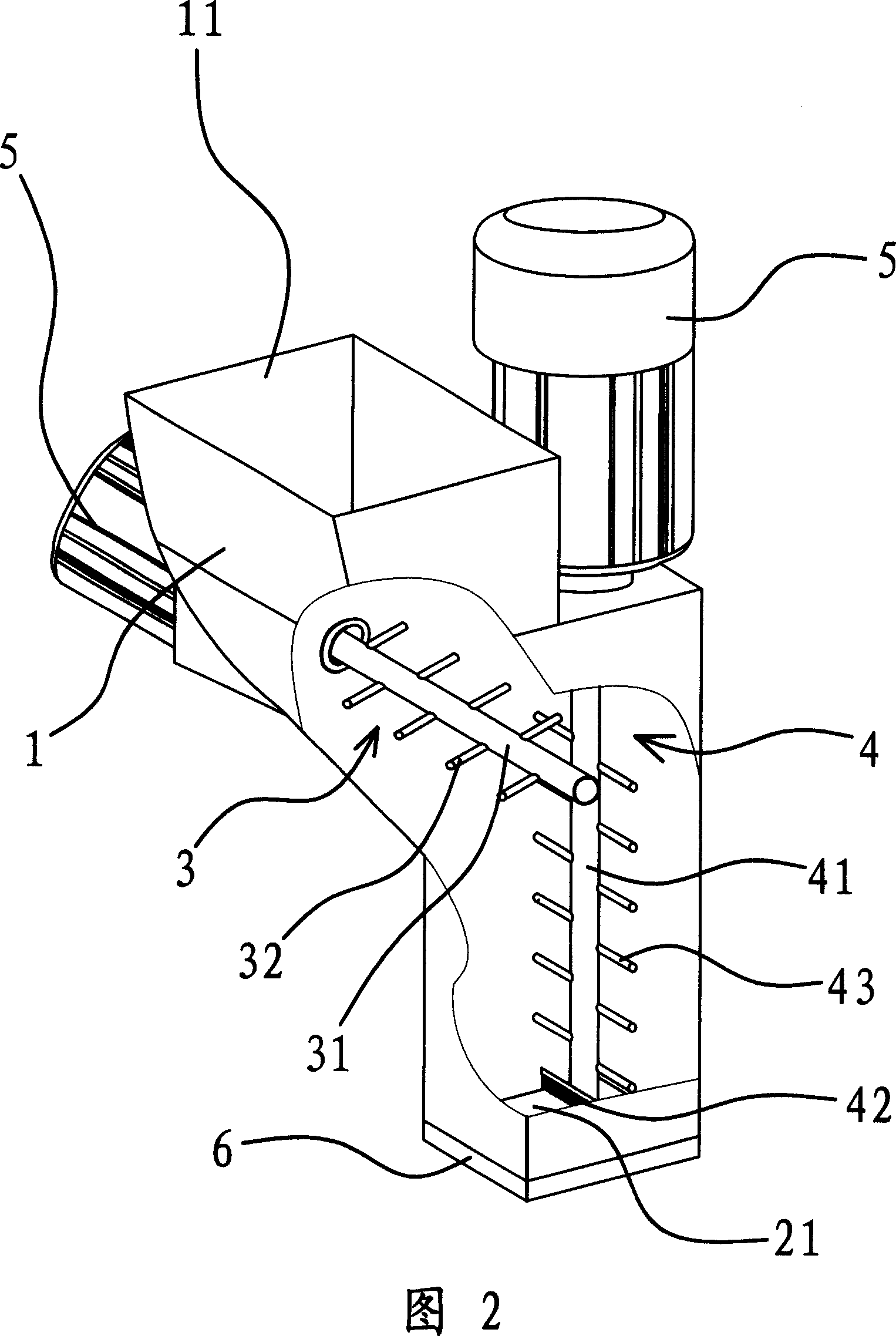

[0020] As shown in Figure 1 and Figure 2, the feeding mechanism of the powder compression molding machine is arranged on the frame of the powder compression molding machine, and it is on the stamping die of the powder compression molding machine. It consists of a hopper 1, a feeding cylinder 2, a feeding tooth 3 and a feeding brush 4, etc.

[0021] The hopper 1 is fixedly connected with the frame, and the top of the hopper 1 has a feed opening 11 and the bottom part has a discharge opening 12 . A feeding tube 2 is also arranged on the frame, the side of the feeding tube 2 communicates with the discharge port 12 of the hopper, and the bottom of the feeding tube 2 has a feeding port 21 .

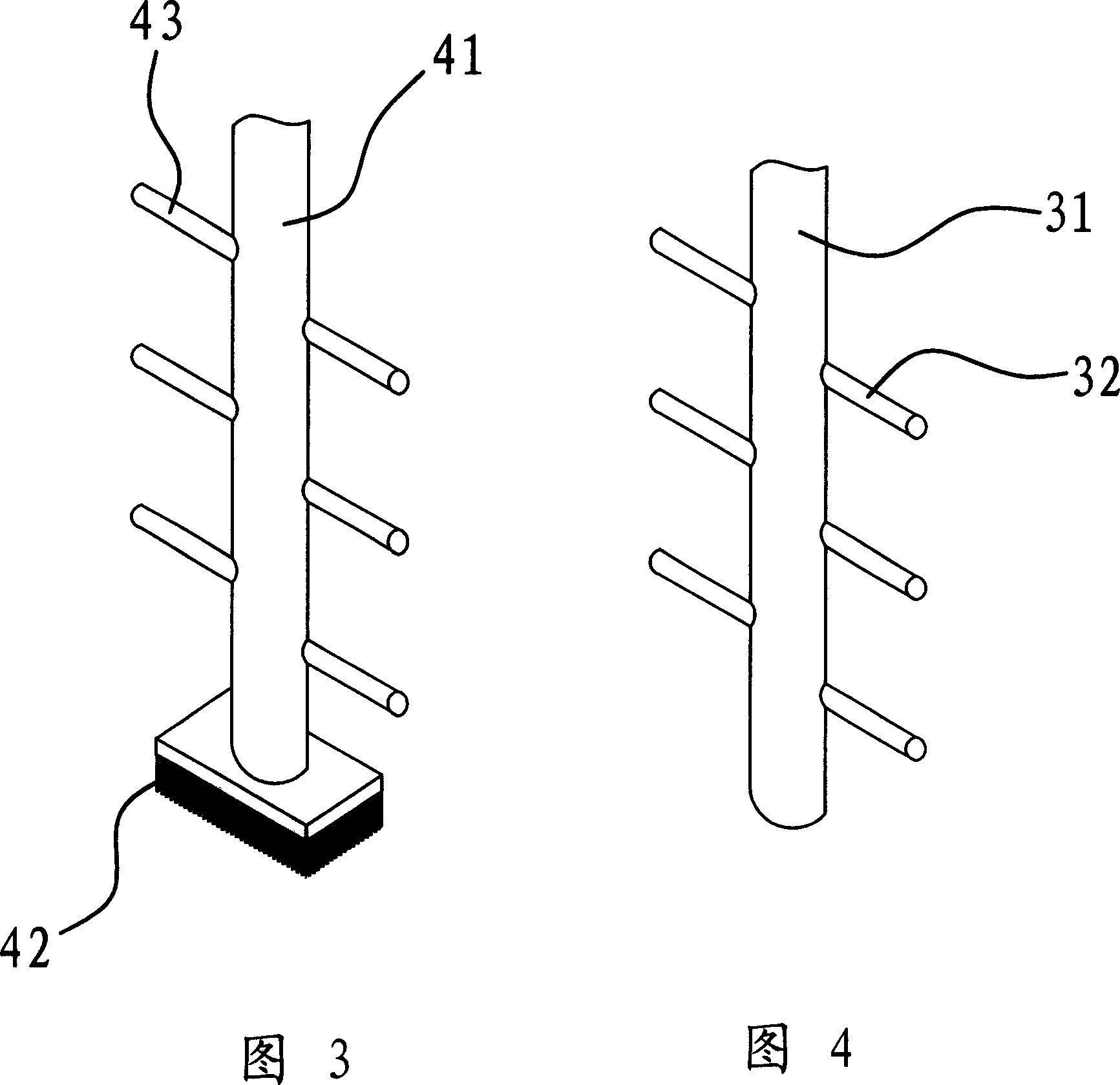

[0022] As shown in FIG. 2 and FIG. 4 , the feed dog 3 is arranged in the hopper 1 and is located at the discharge port 12 . The feed dog 3 is composed of a strip-shaped body 31 and a tooth bar 32 . The outer end of the main body 31 passes through the hopper 1 and is connected to the motor 5 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com