Process for regeneration of waste lubricating oil

A technology of waste lubricating oil and process, applied in the field of waste lubricating oil regeneration process, can solve problems such as environmental pollution, and achieve the effects of less investment, saving resources and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

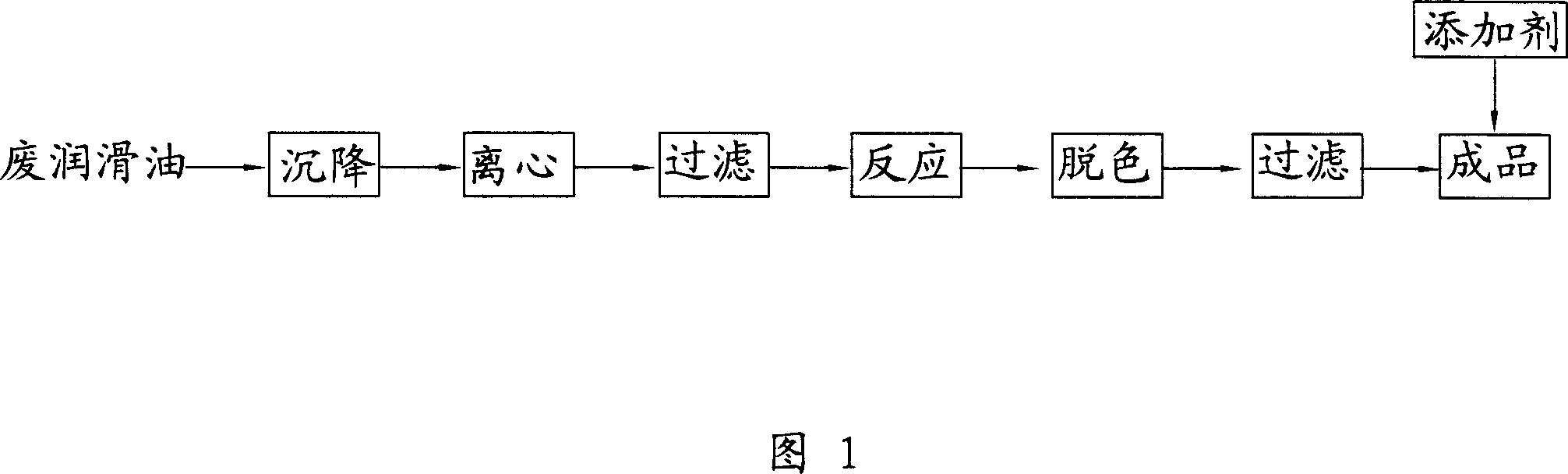

Image

Examples

Embodiment

[0022] Follow the steps below to dispose of used internal combustion engine oil:

[0023] 1) The waste internal combustion engine oil is settled at 45°C-55°C, centrifuged and filtered;

[0024] 2) Take step 1) waste internal combustion engine oil 60m 3 Heat up to 50°C, add 120L of 50% NaOH solution, stir, when the temperature rises to 55°C, add 40L of 30% hydrogen peroxide solution, continue to heat up to 65°C; settle for 24 hours, cool to room temperature, and let go The miscellaneous oil in the lower part, add the anhydrous AlCl of 0.5% (weight ratio) in the clear oil of the upper part 3 , heated to 80°C under stirring, stirred at constant temperature for 1 hour, cooled to room temperature, decolorized, filtered, and 0.2% (weight ratio) of additives were added to obtain a qualified regenerated lubricating oil; the quality index comparison of the regenerated oil is shown in Table 1.

[0025] The additive is prepared by mixing dialkylated diphenylamine and polymethacrylate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com