Photography system for welding process of compound heat reservoir in carbon dioxide laser-melting argon-arc welding

A carbon dioxide, composite heat source technology, applied in photography, lasers, welding equipment, etc., can solve problems such as time-consuming, inability to guarantee, and lack of flexibility, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation manners and processes are given, but the scope of protection of the present invention is not limited to the following implementations example.

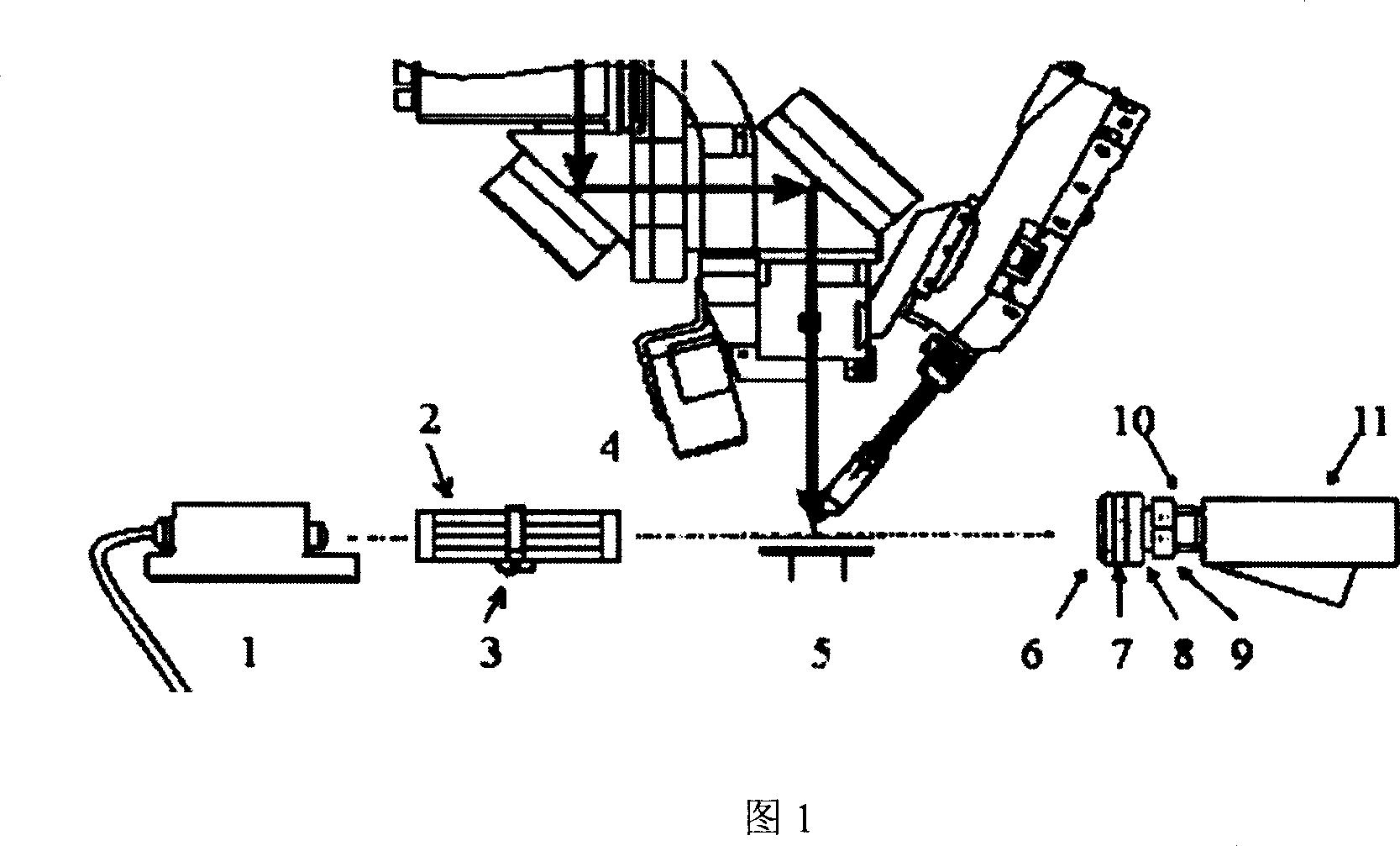

[0018] As shown in Figure 1, this embodiment includes: a semiconductor laser 1, a beam expander 2, a three-dimensional optical adjustment frame 3, a multilayer ultraviolet antireflection film 6, a circular polarizer combination 7, an interference filter 8, a metal threaded interface lens The ring, the photographic lens 9, the adapter 10 and the camera 11. In Figure 1, the carbon dioxide laser-melting argon arc welding compound torch 4 and the workpiece position 5 are experimental facilities.

[0019] Start the semiconductor laser 1, adjust the power to 10mw, make the emitted red laser incident on the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com