Polymer material displaying blue light and preparation method thereof

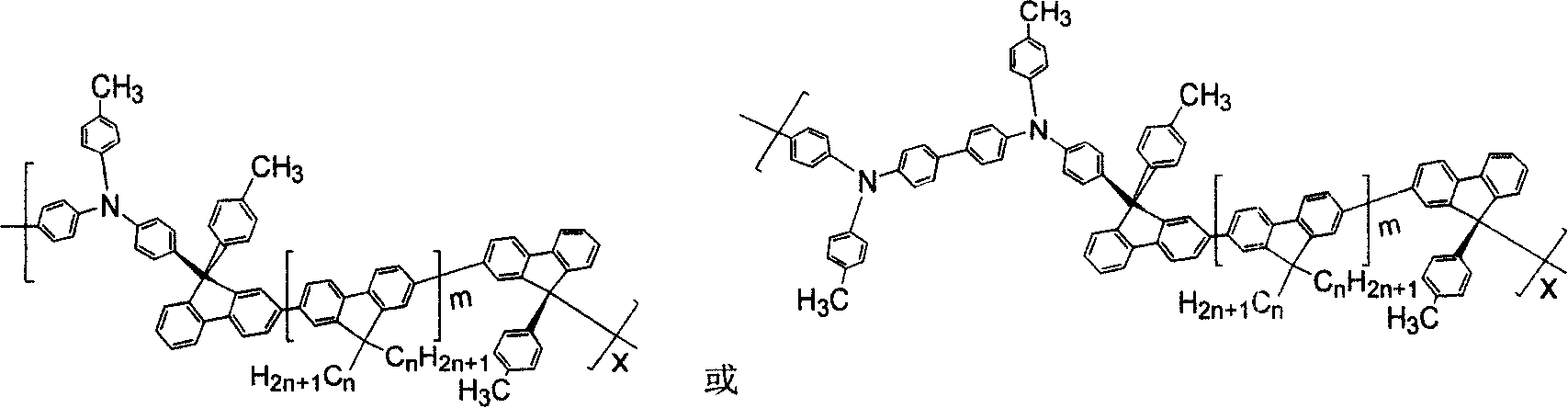

A polymer material and polymer technology, used in the field of organic and polymer chemical synthesis, can solve the problems of low thermal stability, impure blue light, and reduced luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

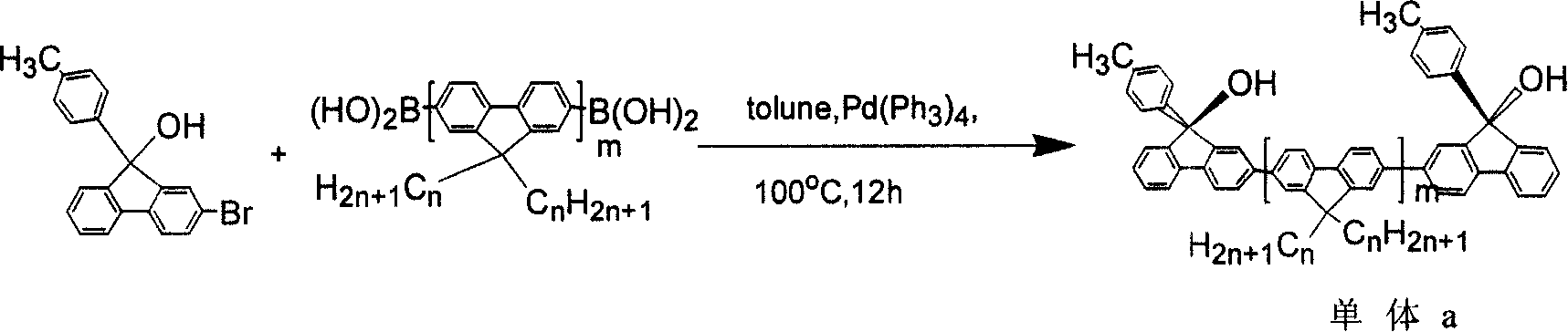

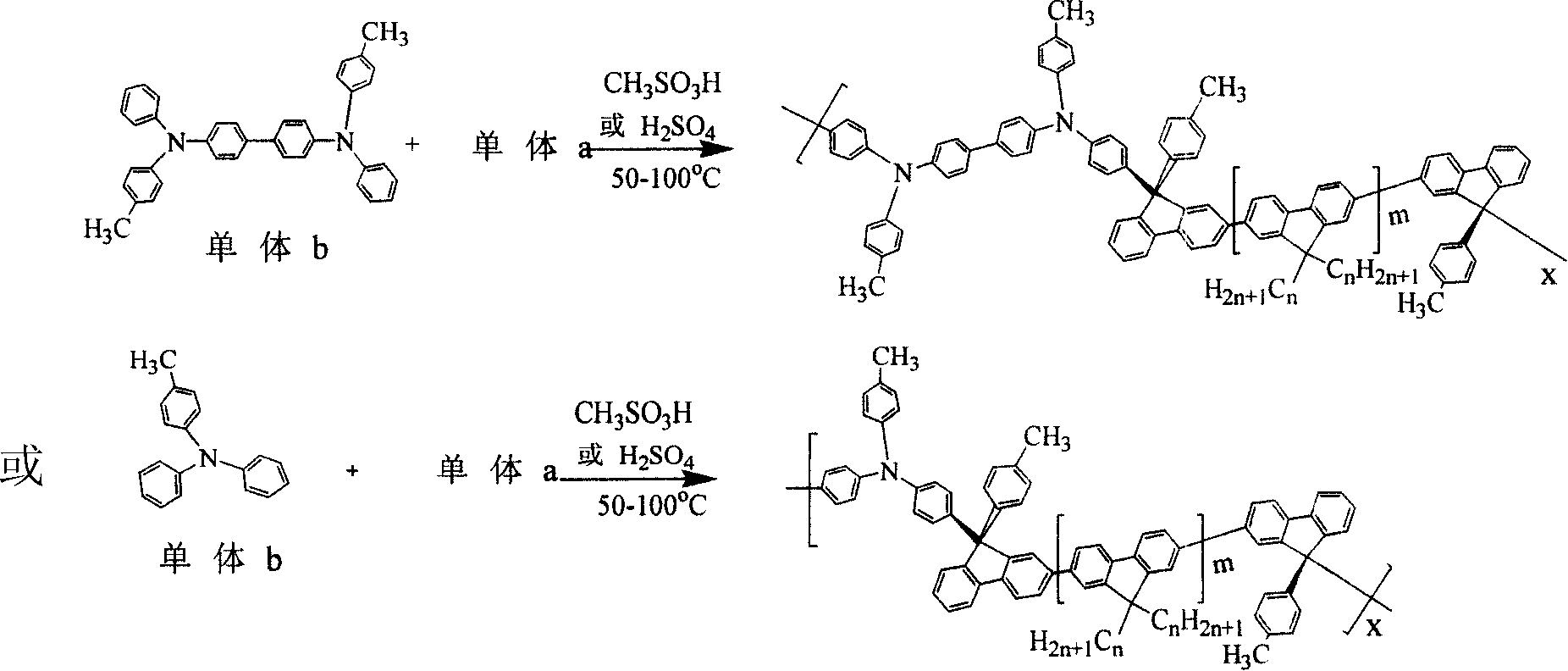

[0024] Monomer b is TPD, monomer a 1 It is a fluorene oligomer containing fluorenol at both ends. Under the catalytic reaction of sulfuric acid, monomer b and monomer a 1 Dehydration and polycondensation into polymers in p-xylene solvent. The reacted solution was dropped into methanol 10 times as solvent to obtain a polymer precipitate, and the product was a light yellow powder solid with a yield of 85%. The molecular weight of the polymer is 30,000, and the degree of polymerization dispersion is 2.1. The synthesis process is shown in chemical reaction formula 5. Main properties of the polymer: glass transition temperature 165°C. The 5% thermal decomposition temperature is 430°C, and it is blue under ultraviolet light, and the photoluminescence efficiency of the solid film is 49%.

[0025]

[0026] Chemical Reaction Formula 5

example 2

[0028] Monomer b is TPD, monomer a 2 It is a fluorene oligomer containing fluorenol at both ends. Under the catalyzed reaction of methanesulfonic acid, monomer b and monomer a 2 Dehydration and polycondensation into polymers in mesitylene solvent. The reacted solution was dropped into methanol 10 times as solvent to obtain a polymer precipitate, and the product was a white or light yellow powder solid with a yield of 85%. The molecular weight of the polymer is 25,000, and the polymerization dispersion is 1.8. The synthesis process is shown in chemical reaction formula 6. Main properties of the polymer: glass transition temperature 234°C. The 5% thermal decomposition temperature is 437°C, and it is blue under ultraviolet light, and the photoluminescence efficiency of the solid film is 43%.

[0029]

[0030] Chemical Reaction Formula 6

example 3

[0032] Monomer b is TPA, monomer a 3 It is a fluorene oligomer containing fluorenol at both ends. Under the catalyzed reaction of methanesulfonic acid, monomer b and monomer a 3 Dehydration and polycondensation into polymers in mesitylene solvent. The reacted solution was dropped into methanol 10 times as solvent to obtain a polymer precipitate, and the product was a white or light yellow powder solid with a yield of 80%. The molecular weight of the polymer is 20,000, and the polymerization dispersion is 2.3. The synthesis process is shown in chemical reaction formula 7. Main properties of the polymer: Glass transition temperature 198°C. The 5% thermal decomposition temperature is 435°C, and it is blue under ultraviolet light, and the photoluminescence efficiency of the solid film is 42%.

[0033]

[0034] Chemical Reaction Formula 7

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com