Electroluminescence element and display device using the same

A technology of electroluminescent elements and light-emitting layers, which is applied in the direction of electroluminescent light sources, electrical components, electric light sources, etc., can solve the problems of reduced light displayed, reduced luminous efficiency of EL elements, and inability to extract light from the light-emitting layer, etc., to achieve Effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

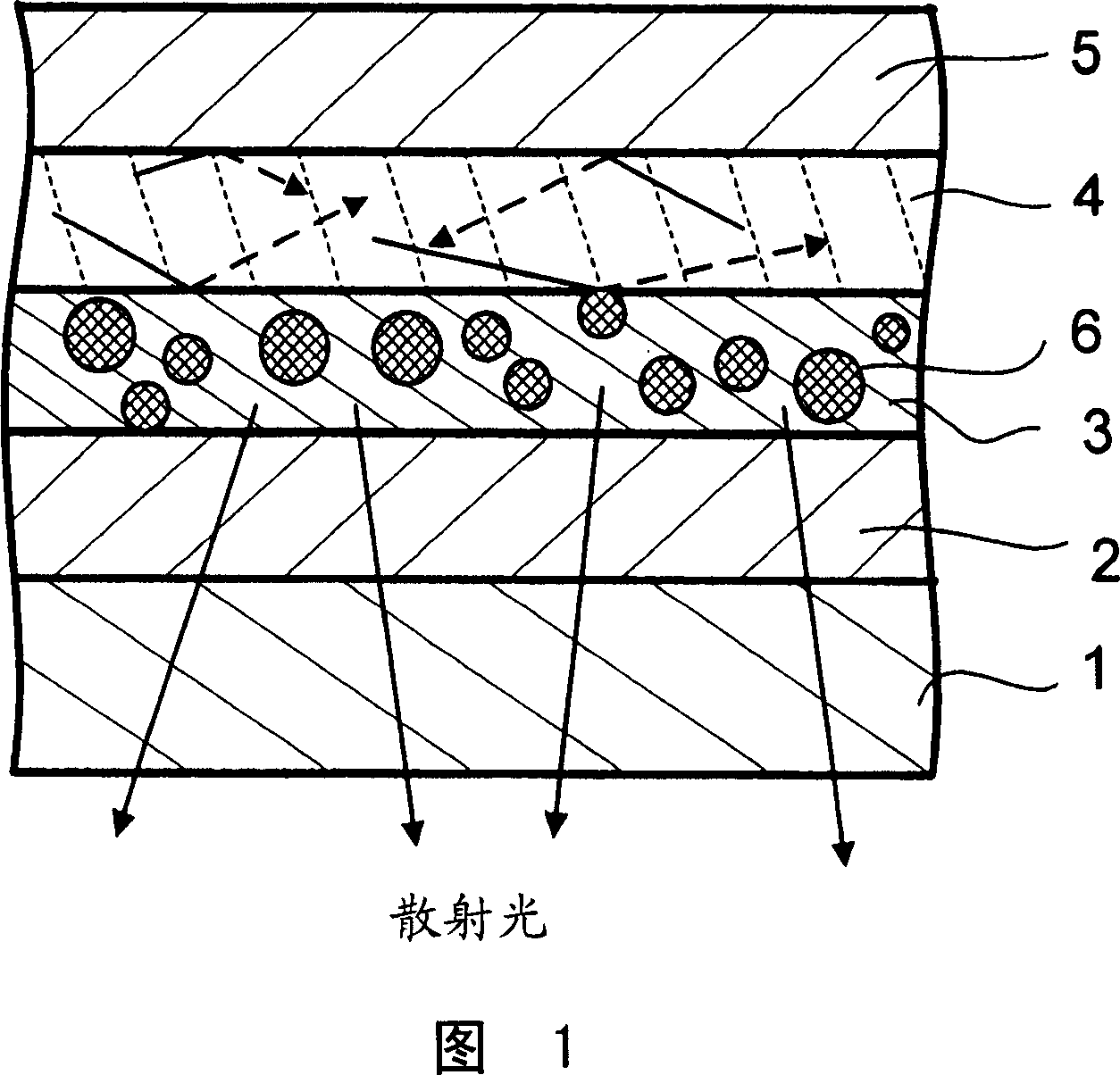

[0050] The EL element according to the present embodiment will be described with reference to FIG. 1 . As shown in FIG. 1 , a transparent first electrode layer 2 is formed on a transparent substrate 1 . Then, a light scattering layer 3 in which metal particles 6 are dispersed in a dielectric material is formed on the first electrode layer 2 . Then, the light emitting layer 4 and the second electrode layer 5 are formed on the light scattering layer 3 . In this embodiment, an EL element used as a flat light emitting panel will be described. This EL element can be used for a lighting device provided in the back of a liquid crystal display device. As shown in FIG. 1, a light scattering layer in which metal particles are dispersed is formed between the first electrode layer and the light emitting layer. For this, light collides with metal particles so that the light can be extracted.

[0051] A voltage is applied between the first electrode layer and the second electrode layer ...

Embodiment 2

[0068] Fig. 7 is a partial schematic view showing the cross-sectional structure of the EL element according to this embodiment. An important difference between the EL element according to this embodiment and the EL element according to Embodiment 1 is that the light scattering layer 3 is provided not between the first electrode layer and the light emitting layer but on the second electrode layer 5 . Other structures and structural arrangements are the same as those in Embodiment 1, and redundant descriptions are omitted here. In the structure according to this embodiment, an opaque metal electrode is used as the second electrode layer 2 and a transparent electrode layer is used as the second electrode layer 5, so that upper scattered light from FIG. 7 is obtained. The light emitting layer 4 is in contact with the second electrode layer 2 and the second electrode layer 5 . There is thus the advantage that a reduction in the voltage applied to the light-emitting layer 4 or a su...

Embodiment 3

[0070] FIG. 9 is a partial schematic diagram showing a cross section of the EL element according to this embodiment. A structure in which an EL element according to the present invention is used for a display device will be described. Here, an example of an EL element in which a plurality of electrodes spaced apart from each other are formed corresponding to three kinds of light scattering regions will be described. As shown in Figure 9, the first electrode layer 2 is formed on a transparent substrate 1 made of glass or the like, and the first electrode layer 2 is a plurality of spaced strip electrodes extending parallel to the paper plane direction of Figure 9 one of the group. The light scattering layer 3 is formed on the first electrode layer 2 . The light emitting layer 4 is formed on the light scattering layer 3 . The second electrode layer -B 5b , the second electrode layer -G 5g , and the second electrode layer -R 5r spaced apart from each other and provided in strip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com