Structure of preventing sticking and method of preparing the same

An anti-adhesive and structural body technology, applied in polyurea/polyurethane coatings, layered products, coatings, etc., can solve problems such as pollution, no prevention method proposed, difficulty in monitoring and preventing attachments, etc., to reduce the contact area , excellent anti-pollution properties, and improved weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

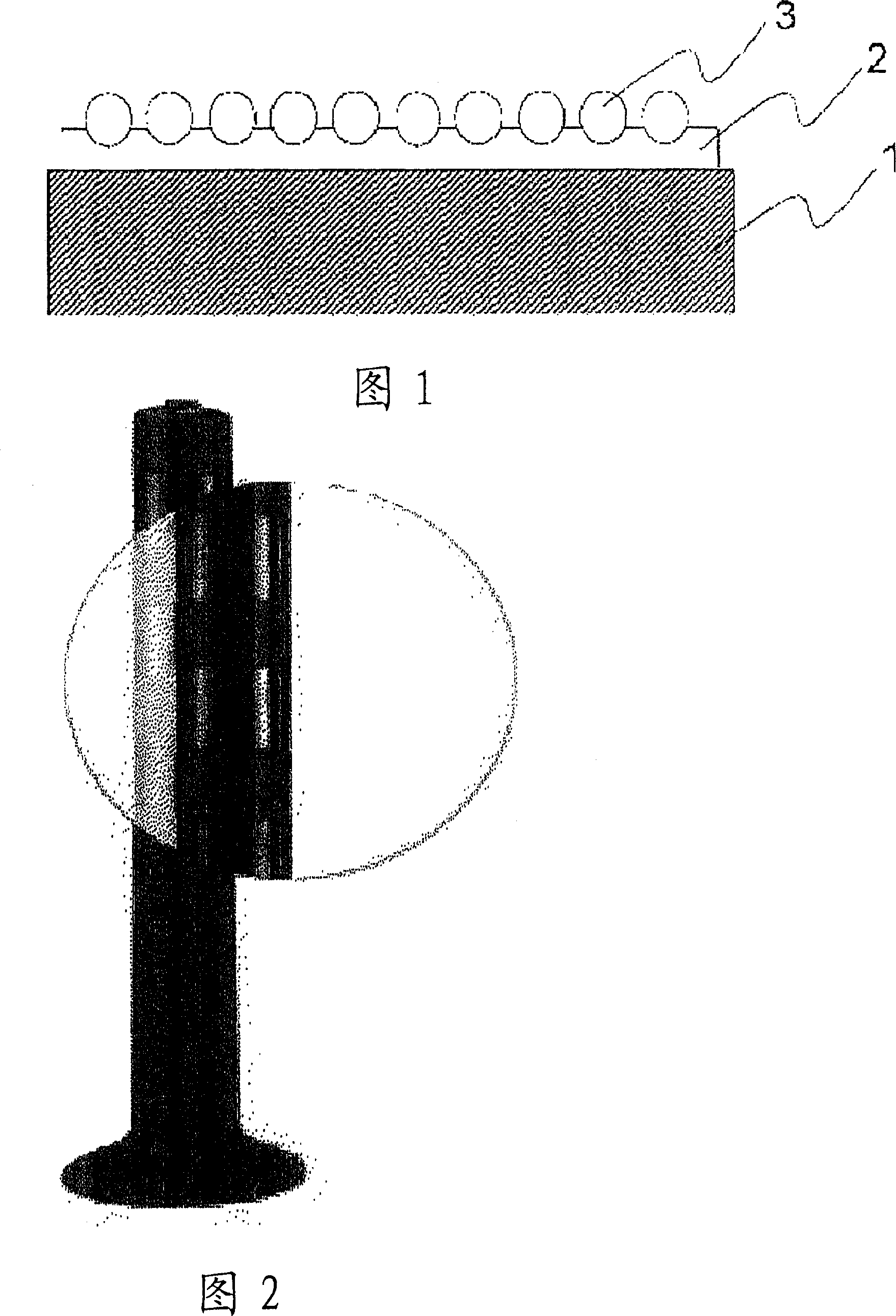

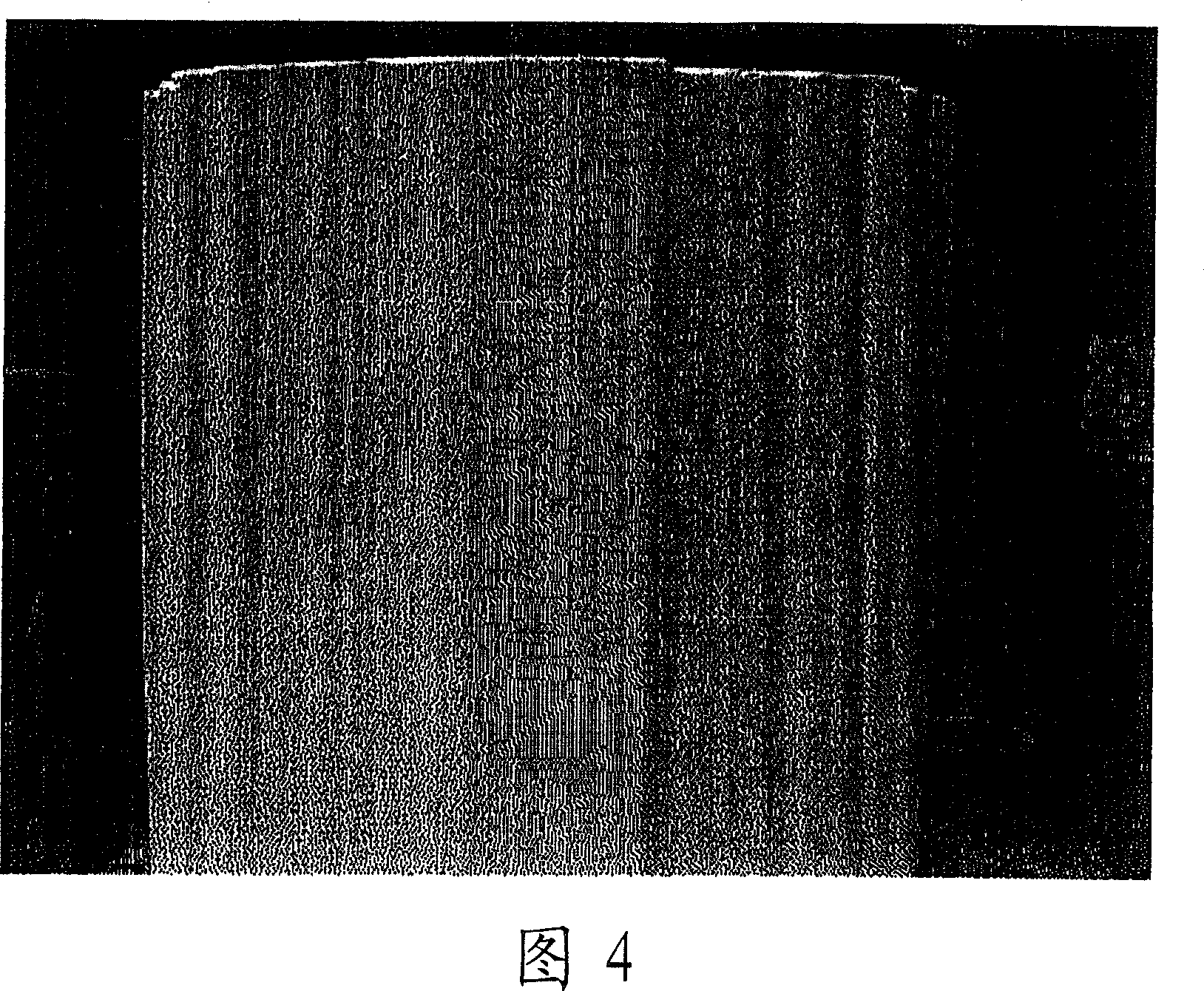

[0085] A non-adhesive structure having adhered glass beads protrusions on the polyurethane resin surface was prepared by the following method: 1 kg of polyurethane resin was coated on steel, aluminum, resin frame, transparent resin plate, glass and concrete of 25 cm x 15 cm, respectively, Each was made to have a thickness of 1 mm, and 800 g of glass beads having an average diameter of 0.1 mm were sprayed and hardened before the polyurethane resin was hardened. Specifically, a resin frame to which a release structure is applied is shown in FIGS. 3 and 4 .

[0086] A tape with an adhesive thereon was adhered to one side of each of the above prepared steel, aluminum, resin frame, transparent resin plate, glass and concrete with a release structure. As a result, the tape will not stick to any of steel, aluminum, resin frames, clear resin panels, glass, and concrete. In addition, steel, aluminum, resin frames, transparent resin panels, glass, and concrete with a non-stick structur...

Embodiment 2

[0089] A release structure was prepared in the same manner as in Example 1 except that glass beads having an average diameter of 50 μm were used.

[0090] For steel, aluminum, resin frame, transparent resin board, glass, and concrete on which the anti-adhesive structure was formed, the tape adhesion test was performed using the same method as in Example 1. As a result, the tape did not stick to any of steel, aluminum, resin frame, transparent resin board, glass, and concrete, and the tape could be easily peeled off even when a great pressure was applied during the sticking Lose.

Embodiment 3

[0092] 1kg polyurethane resin and 1kg average diameter are 200 order, specific gravity is the glass powder of 2.54, coat this mixture respectively on steel, aluminum, resin frame, transparent resin plate, glass and concrete, then by implementing and embodiment 1 The anti-adhesive construct was prepared in the same manner as in . The tape adhesion test was carried out using the same method as in Example 1, and the results showed that the anti-adhesive effect was the same as in Example 1.

[0093] In addition, external pressure was applied to the release structures prepared in Example 1 and Example 3 to see if the glass beads fell off. As a result, the anti-adhesion structure of Example 3 to which the glass powder was added had a more excellent bonding ability to glass beads than the anti-adhesion structure of Example 1 in which the glass powder was not used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com