Digital holographic micro-measuring device

A digital holographic microscope and measuring device technology, which is applied in measuring devices, microbial measurement/inspection, and material analysis through optical means, can solve problems such as limiting depth, achieve simple and compact devices, expand depth measurement range, and dynamically good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A preferred embodiment of the present invention is described in detail as follows:

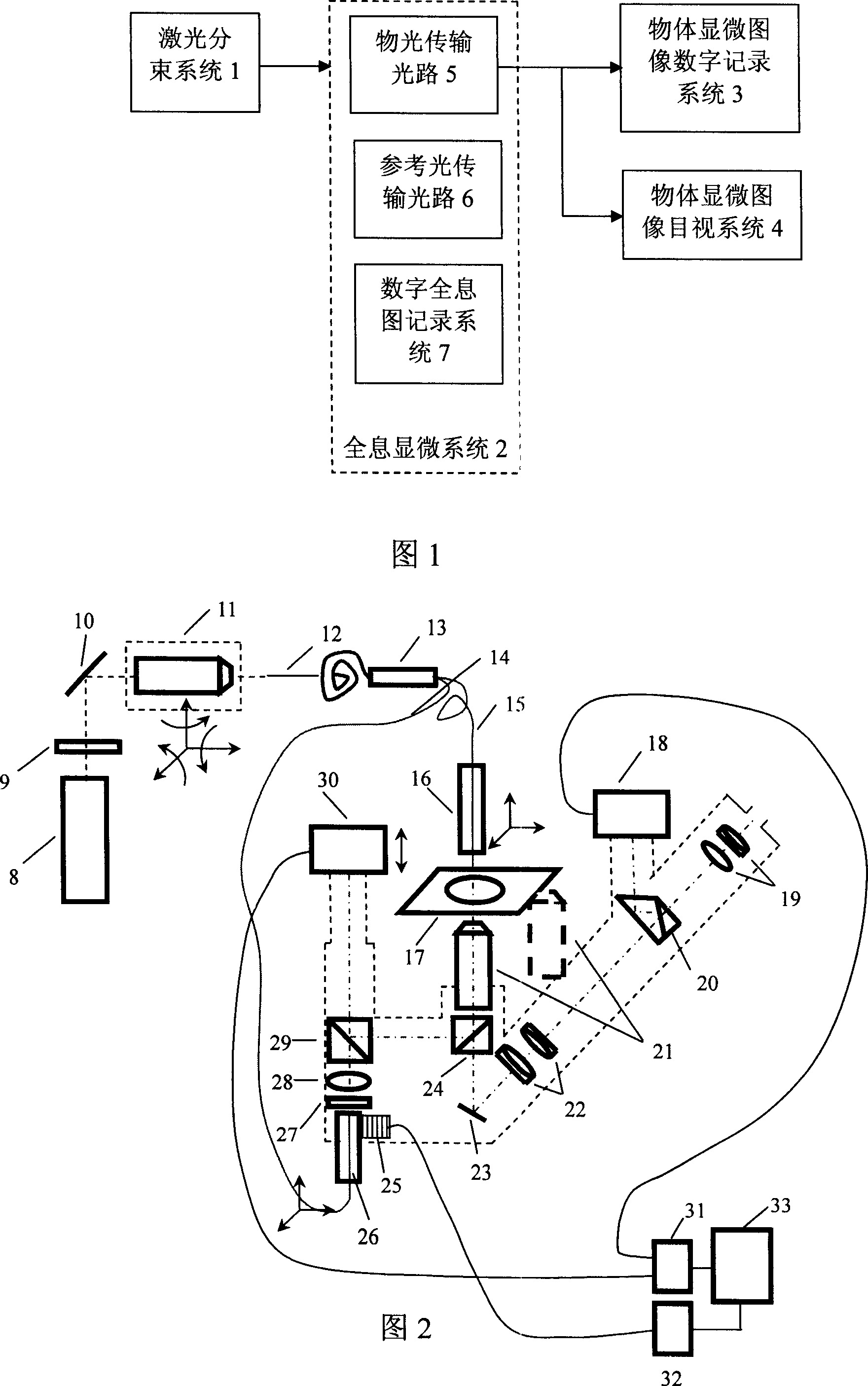

[0020] Referring to Fig. 1, the digital holographic microscopic measurement device is composed of a laser beam splitting system (1) connected to an object microscopic image digital recording system (3) via a micro-holographic system (2), the micro-holographic system (2) It consists of a laser beam splitting system (1) connected to an object microscopic image digital recording system (3) via a holographic microscopic system (2), and the holographic microscopic system (2) is composed of an object light transmission optical path (5), the reference light transmission optical path (6) and the digital hologram recording system (7) are composed, it is characterized in that the output of the holographic microscopic system (2) is also connected to an object microscopic image visual system (4 ).

[0021] Referring to Fig. 2, the above-mentioned object microscopic image vision system (4) is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com