Encapsulation structure of optical sensing element with micro-packaging area

A packaging structure and light sensing technology, which is applied to color TV parts, TV system parts, electrical components, etc., can solve the problems of large wasted area, waste of area, waste of length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

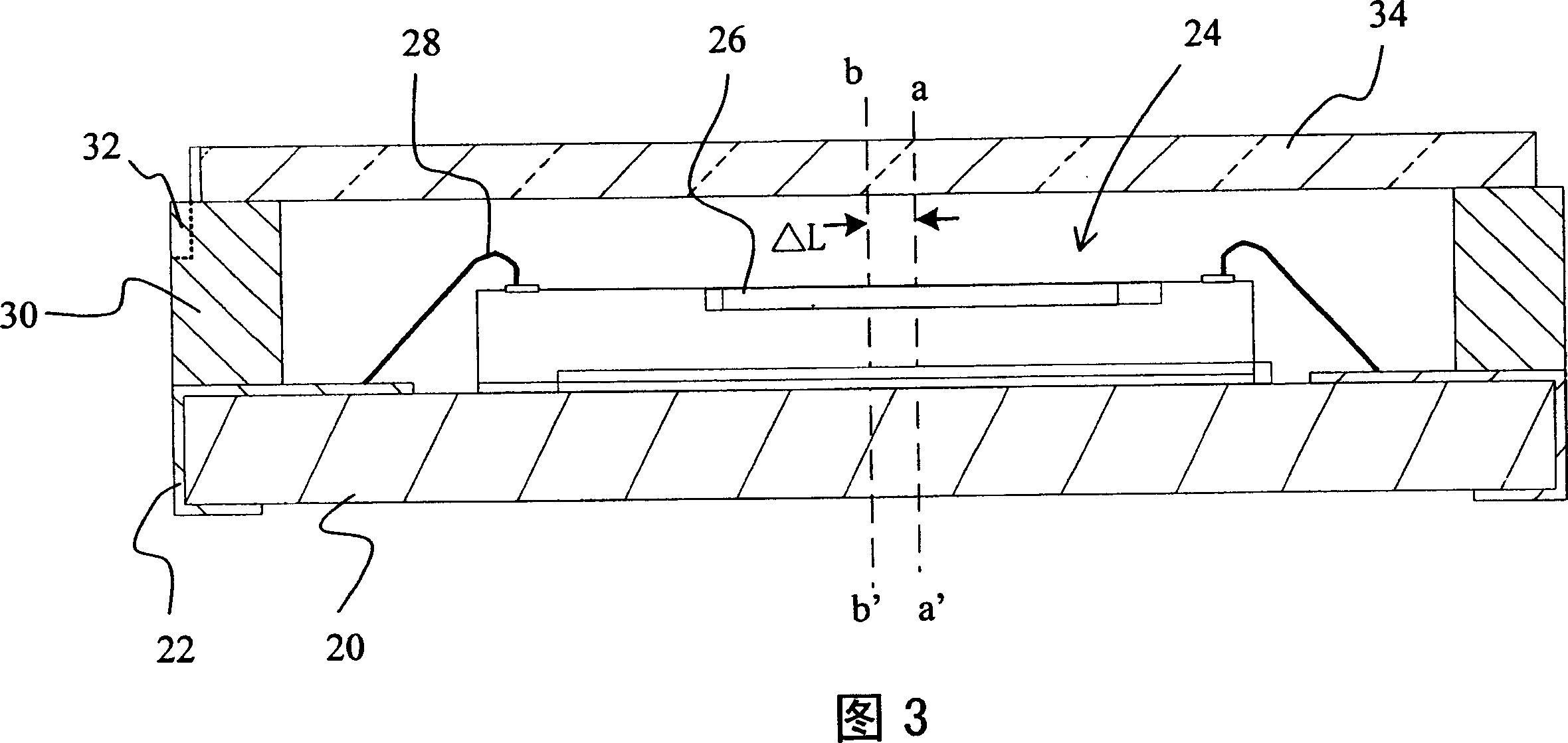

[0050] The invention relates to a packaging structure of a photo-sensing component with a small construction area, which can meet the requirements of light, thin, short and small packaging of a portable photo-sensing component.

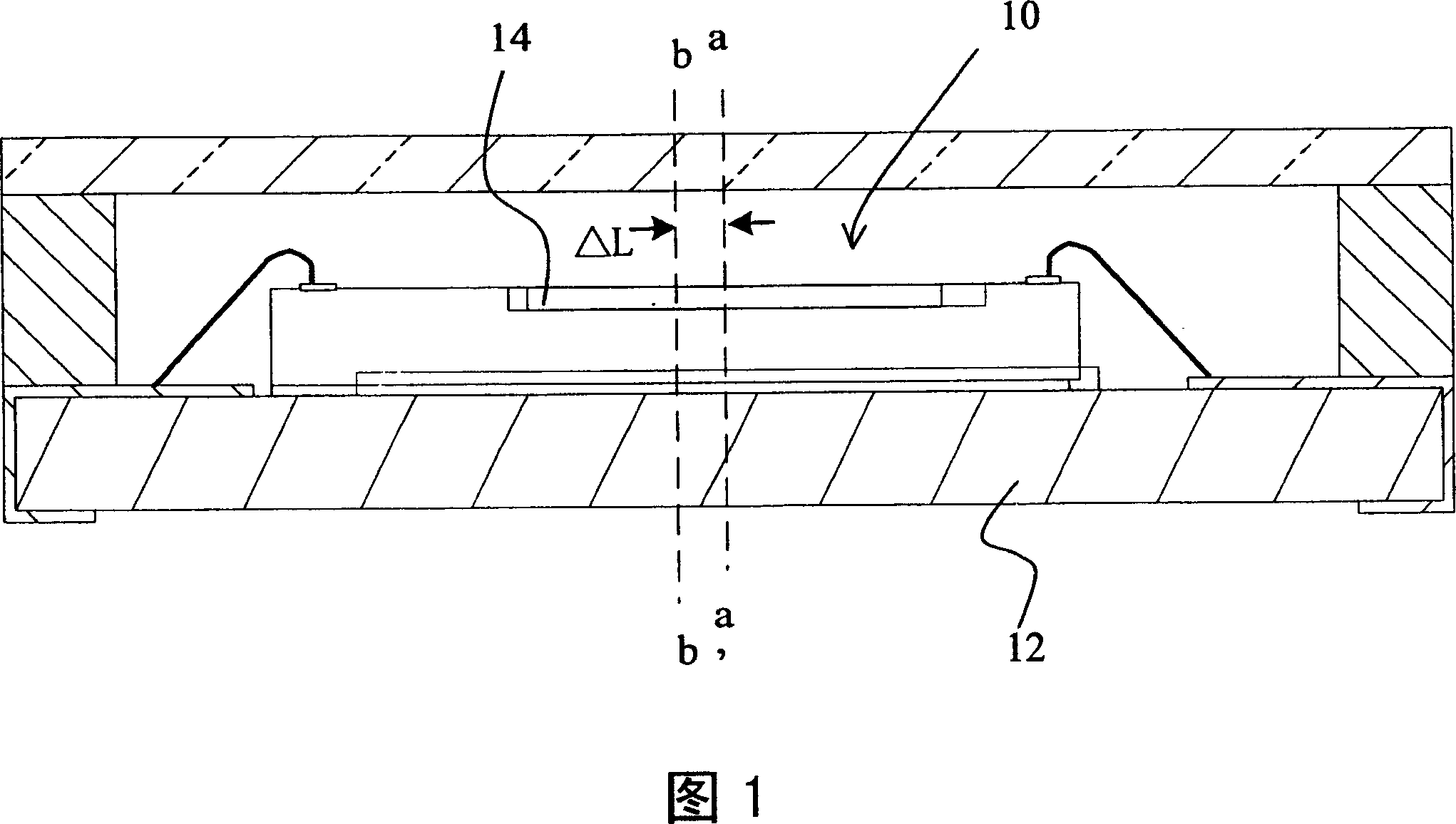

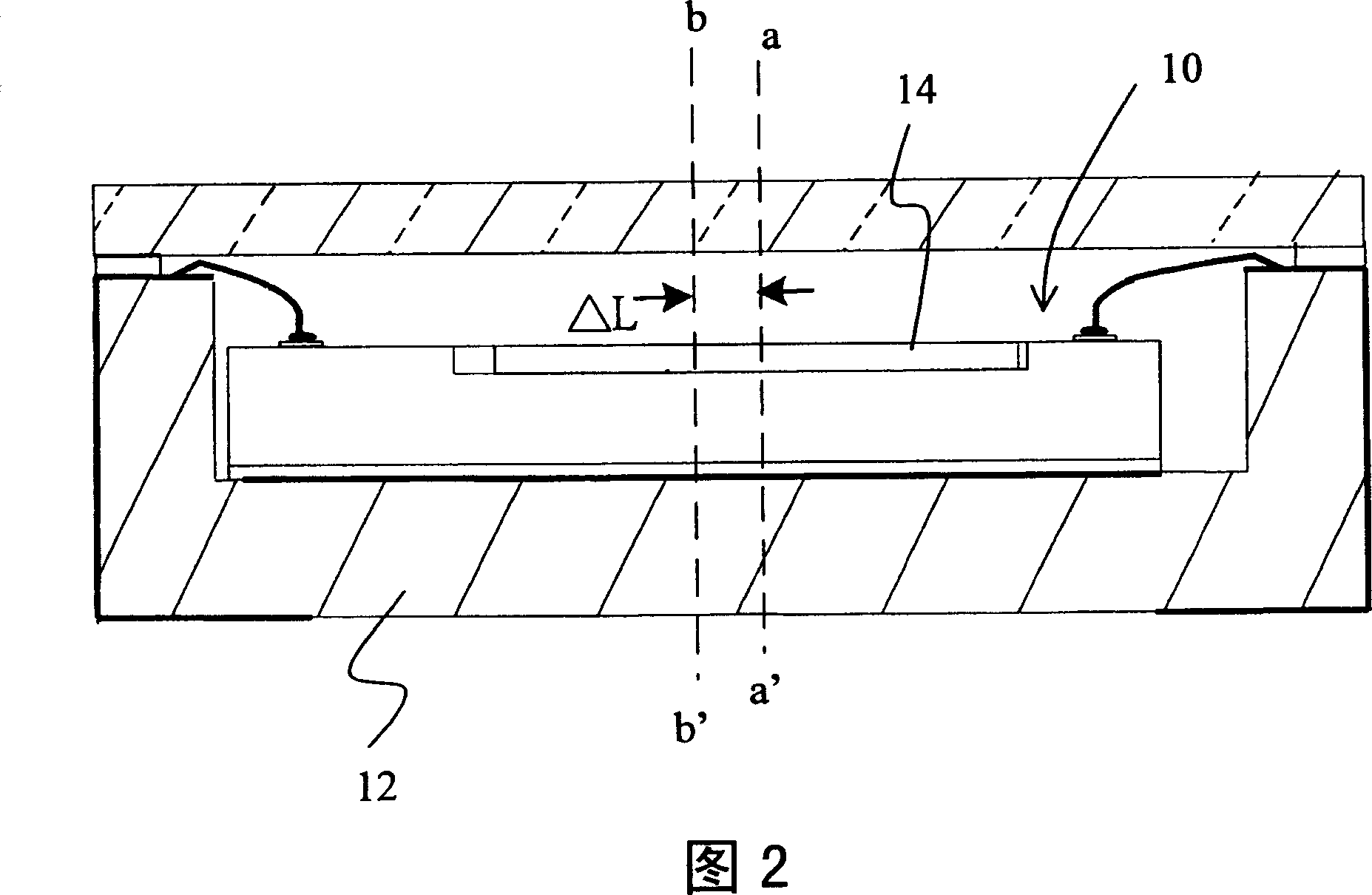

[0051] First, please refer to FIG. 3 , which is a schematic diagram of a specific embodiment of the present invention. As shown in the figure, the present invention includes a substrate 20 which may be rectangular or square, and metal wiring 22 is formed at an appropriate position on the substrate 20. In this figure, the metal wiring 22 extends from both sides of the upper surface of the substrate 20 to the lower surface. To facilitate subsequent electrical connection with a PCB board (not shown in the figure) packaging; an optical sensing component 24 located on the substrate 20, which has an optical sensing region 26 and the centerline of the optical sensing component 24 (bb') is located at the center position of the substrate 20 (at this time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com