Gold-wire-free encapsulation method of large power white light LED part and white light LED part

A technology for LED devices and packaging methods, which is applied in the direction of electric solid devices, semiconductor devices, electrical components, etc., can solve the problems affecting the injection efficiency and forward working voltage of LED devices, the large contact resistance between the gold wire and the chip contact point, the phosphor and the filling The problem of low thermal conductivity of the sealant can improve the light emitting efficiency of LEDs, solve the shortcomings of the gold wire process, and reduce the package area and package thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation of the transparent conductive film and the conductive metal electrode adopts a photoetching method, a mask method, a laser dry etching method, a screen printing method or a through-mask deposition method.

[0053] Using transparent conductive films and conductive metal electrodes instead of gold wires for packaging can effectively increase the light-emitting area of LED light-emitting chips, increase luminous flux, and improve LED light-emitting efficiency.

[0054]The above-mentioned transparent conductive film, conductive metal electrode and their preparation methods are all prior art, and their specific methods and processes will not be described here.

[0055] Furthermore, the single crystal fluorescent material functional unit is arranged on at least one side of the chip. As a special case, the single crystal fluorescent material functional unit can be arranged on two sides of the chip to form a double-sided light-emitting device.

[0056] The tr...

Embodiment 1

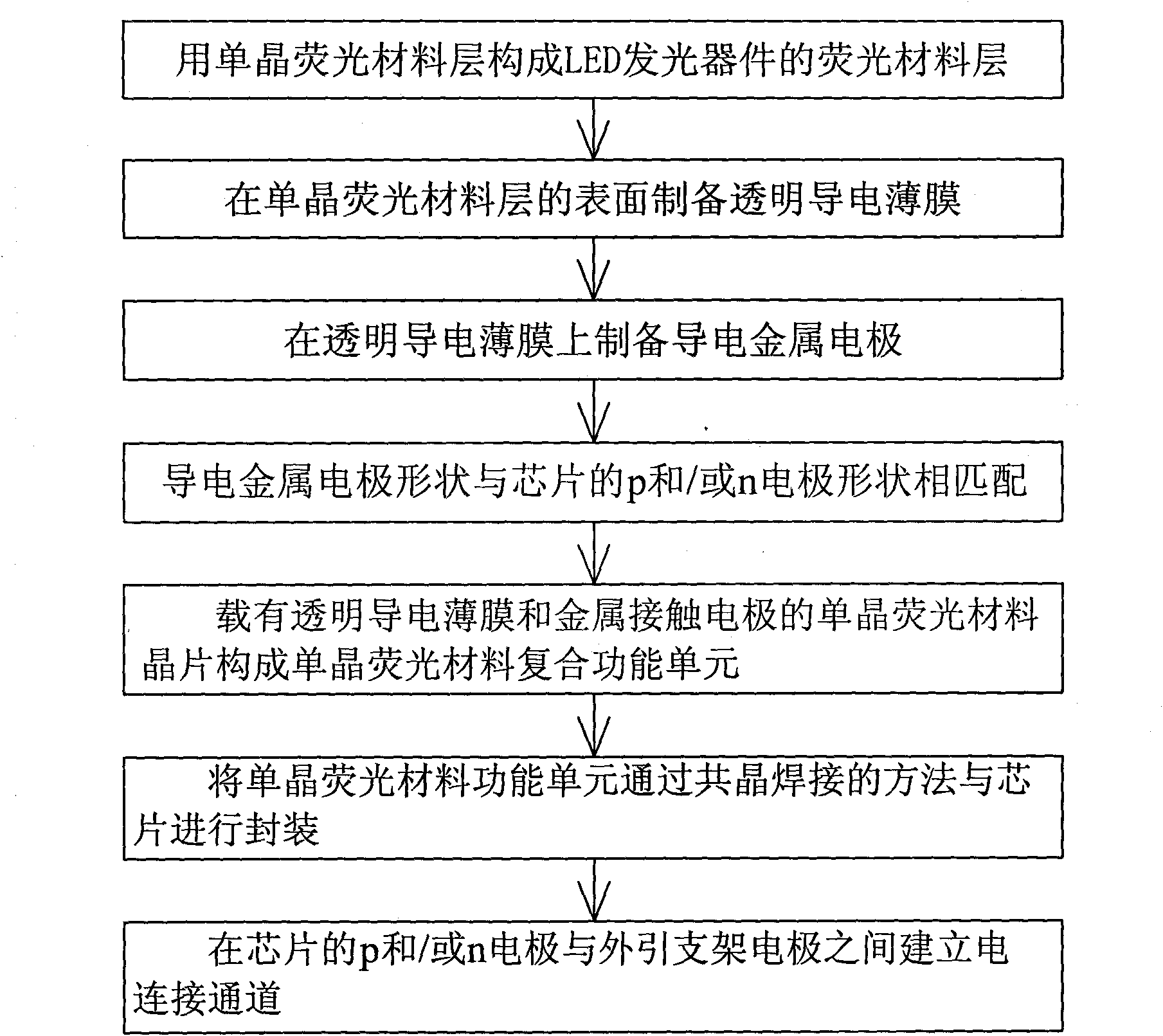

[0060] a use figure 1 The structure of the high-power white LED device manufactured by the packaging method is as shown.

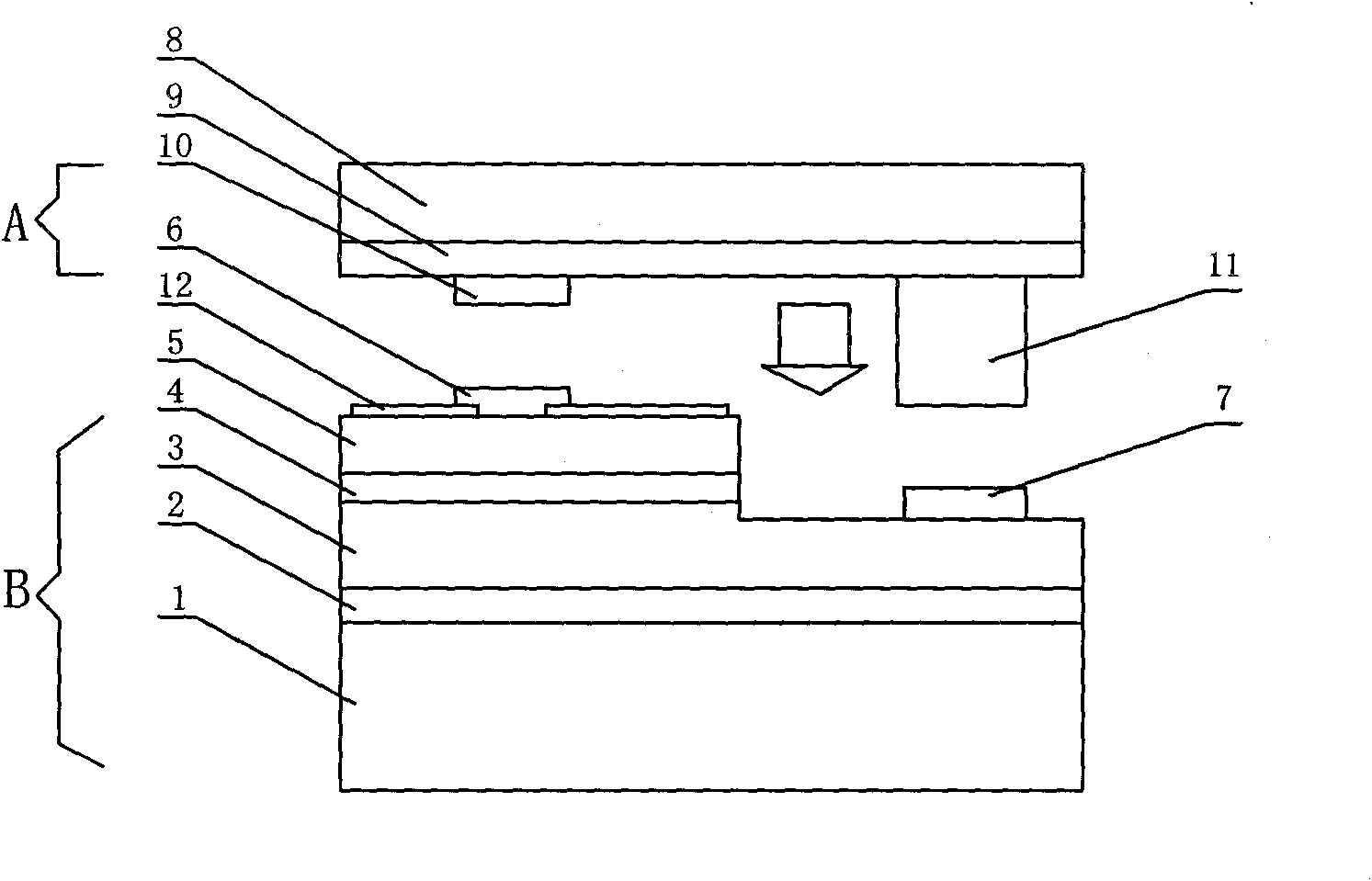

[0061] figure 2 In the structure of conventional LED light-emitting chips, the buffer layer / u-GaN layer 2 is usually set on the substrate layer 1, followed by the n-GaN layer 3, the active region 4 and the p-GaN layer 5, and the n-GaN layer and the On the p-GaN layer, ohmic contact surfaces (ie commonly known as p and / or n electrodes) 6 and 7 for electrical connection and extraction are provided.

[0062] In this technical solution, at least one side of the LED light-emitting chip B is provided with a single crystal fluorescent material functional unit A composed of a single crystal fluorescent material layer 8, a transparent conductive film 9 and conductive metal electrodes 10 and 11 in sequence.

[0063] It can be seen from the figure that the single crystal fluorescent material functional unit forms an electrical connection channel between the pn jun...

Embodiment 2

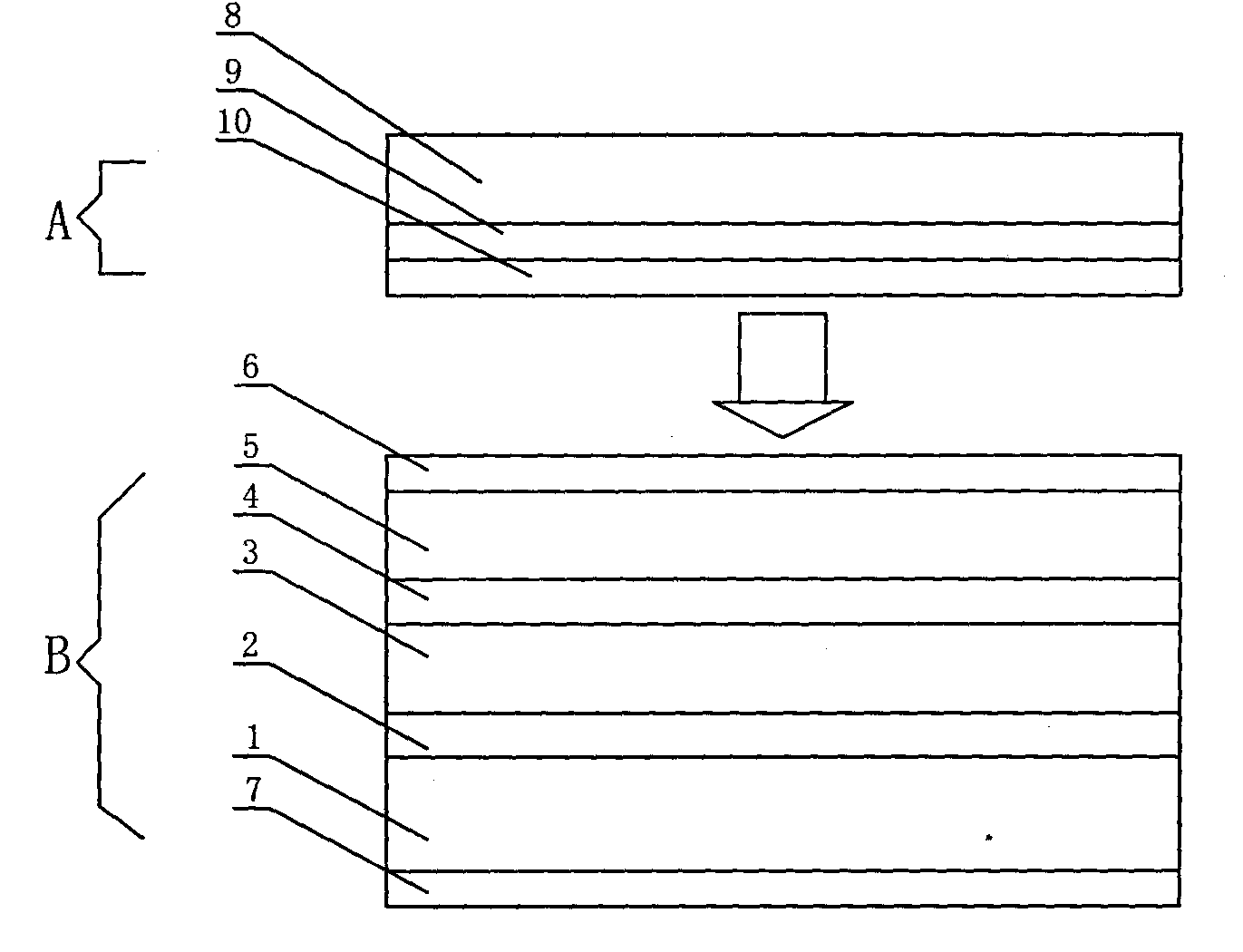

[0074] Another use figure 1 The high-power white light LED device that described encapsulating method manufactures, its structure is as follows image 3 shown.

[0075] image 3 Among them, the LED chip is a vertical structure (Vertical), and the two electrodes 6 and 7 of the vertical structure LED chip are respectively on both sides of the LED epitaxial layer (p-GaN layer 5 and n-GaN layer 3).

[0076] Similarly, when a single-crystal fluorescent material is used as the substrate layer 1 below the n-GaN structure layer 3 in the figure, an LED light-emitting device capable of truly double-sided light-emitting / light-emitting can be formed.

[0077] The rest are the same figure 1 or figure 2 mentioned.

[0078] After adopting the above-mentioned structure, multiple LED light-emitting chips can be arranged simultaneously on one base material by adopting a chip-on-board packaging method, which helps to improve the luminous quantity and luminous flux of a single LED light-emi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com