Firing kiln and process for producing ceramic member therewith

A manufacturing method and component technology, applied in the direction of furnaces, furnace linings, muffle furnaces, etc., can solve problems such as the reduction of the effect of the heat insulation layer, the reduction of the heat insulation of the heat insulation layer, and the deformation of ceramic fibers, so as to prevent cracks, prevent damage, and heat insulation performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

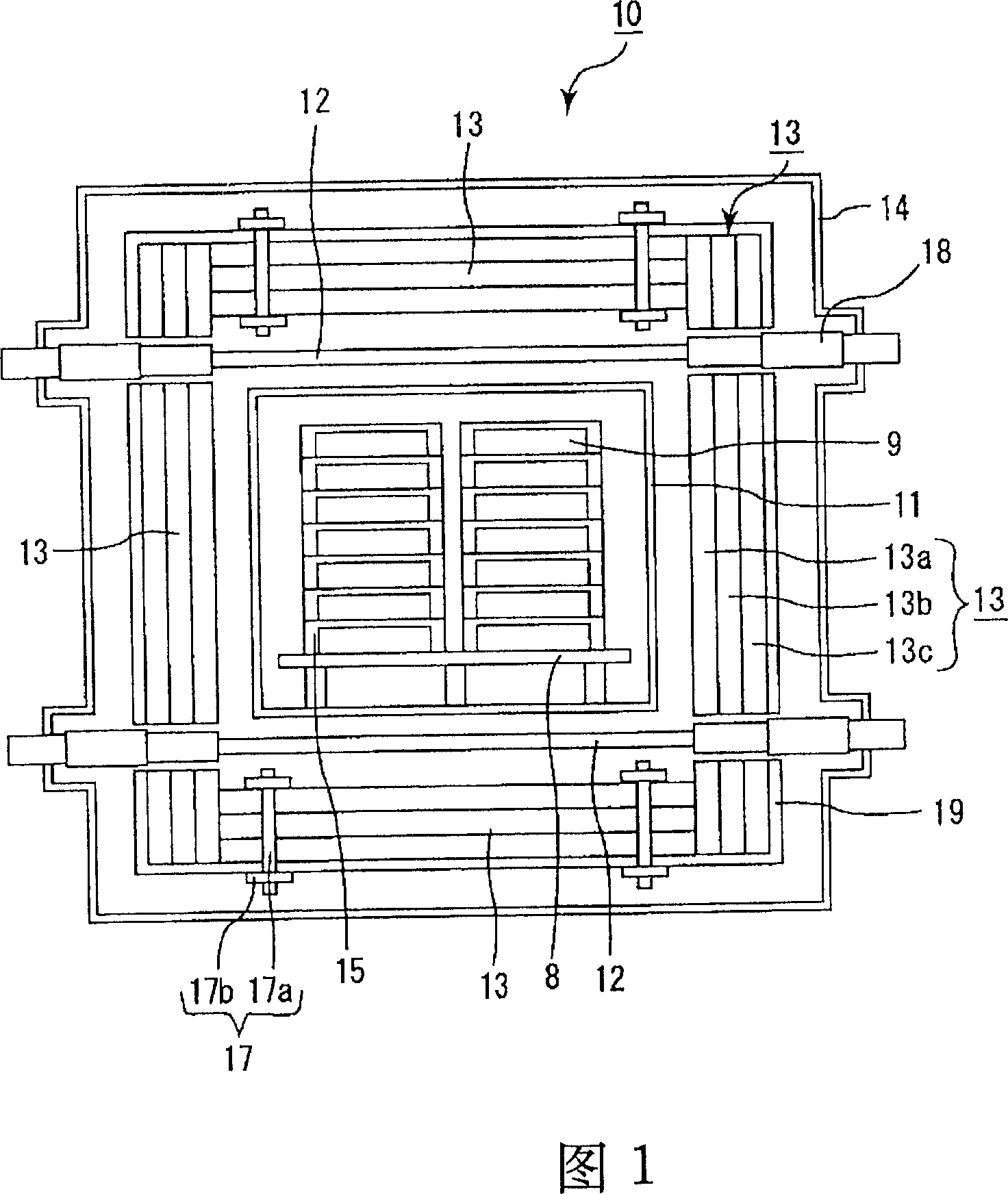

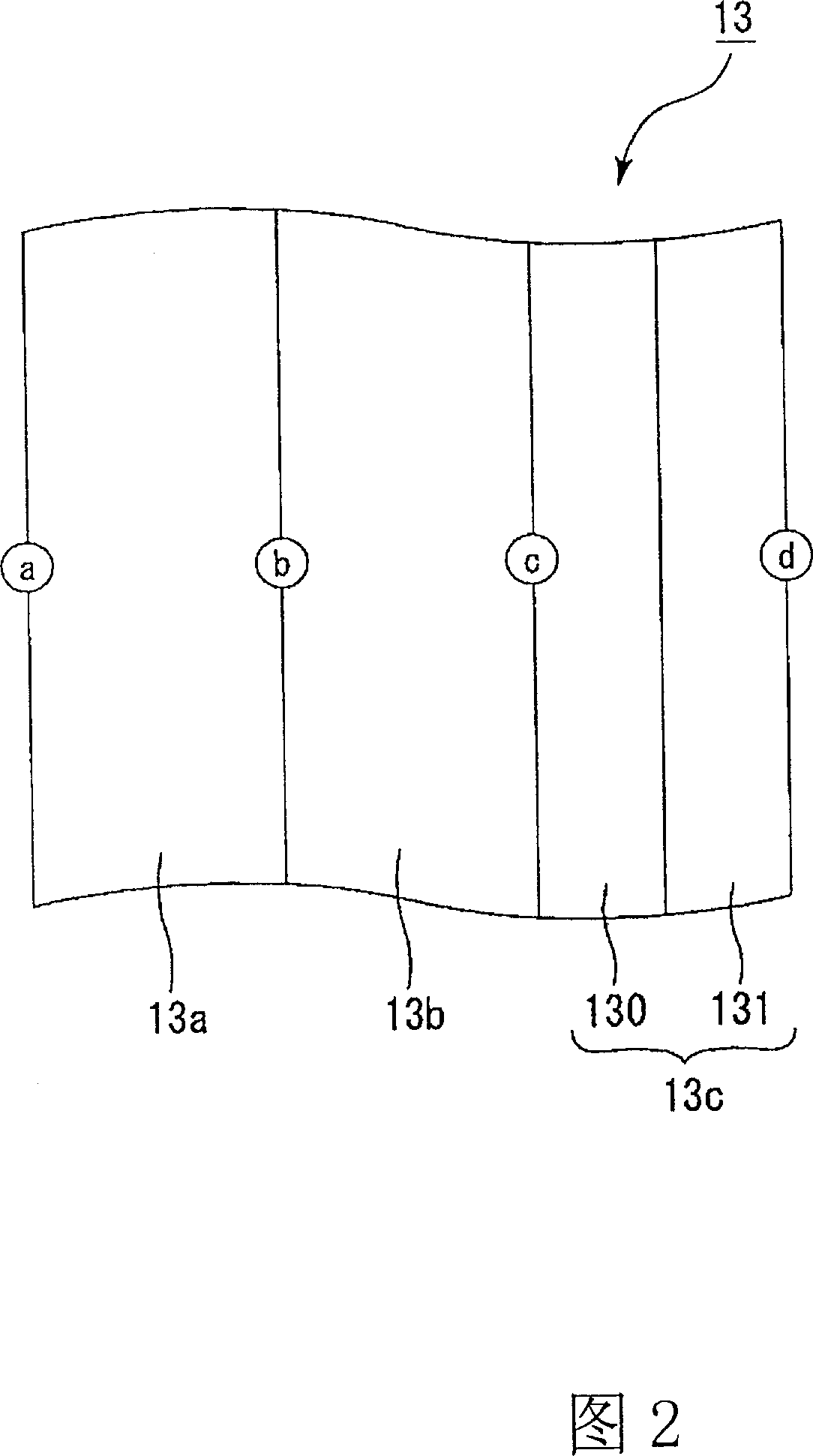

[0100] (1) Fabricate a firing furnace as shown in FIG. 1, and make the innermost layer as a layer 13a made of carbon parts (FR200 / OS manufactured by Kureha Chemical Industry Co., Ltd., density: 0.16 g / cm 3 , thickness: 50mm), the second layer is made of a layer 13b made of carbon parts (FR200 / OS manufactured by Kureha Chemical Industry Co., Ltd., density: 0.16g / cm 3 , thickness: 50mm), while the outermost layer is made of carbon insulation material layer 130 (density: 0.16g / cm 3 , thickness: 25mm) and carbon fiber layer 131 (density: 0.1g / cm 3 , Thickness: 25mm) composite layer (manufactured by Kureha Chemical Industry Co., Ltd.), in an atmosphere of argon gas at normal pressure, set the maximum temperature in the muffle furnace to 2200 ° C, and pass through to the center of the heating chamber Thermocouples were inserted into the heat insulating material, and the temperature of the heat insulating layer 13 was measured at various positions shown in FIG. 2 .

[0101] As a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com