Waterproof zip fastener and its making process

A technology of waterproof zipper and manufacturing method, which is applied in the direction of clothing, fasteners, sliding fastener components, etc., can solve the problems of monotonous plane, cumbersome processing procedures, and inability to produce shape changes, so as to improve attractiveness, simplify production procedures, reduce The effect of processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

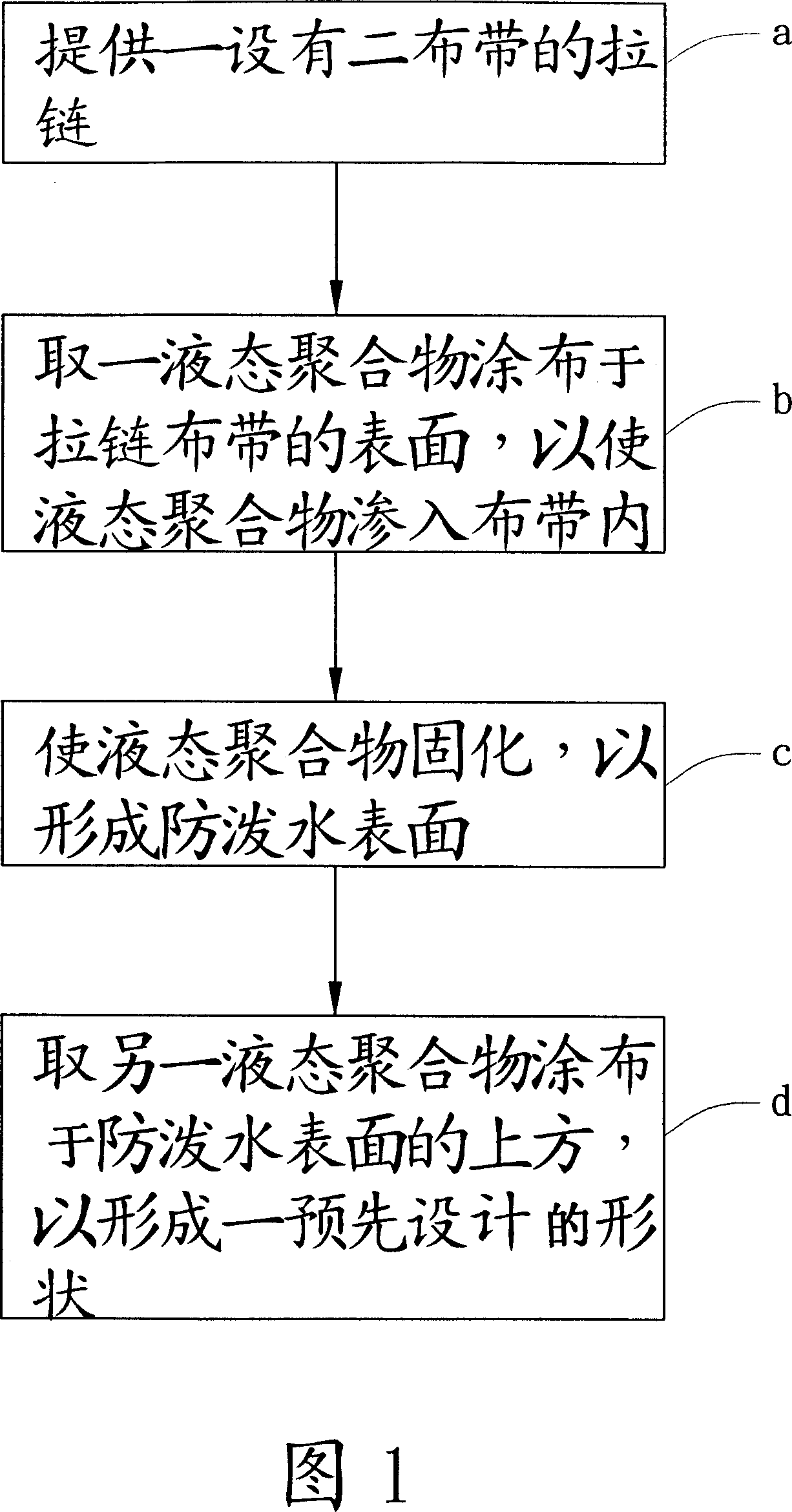

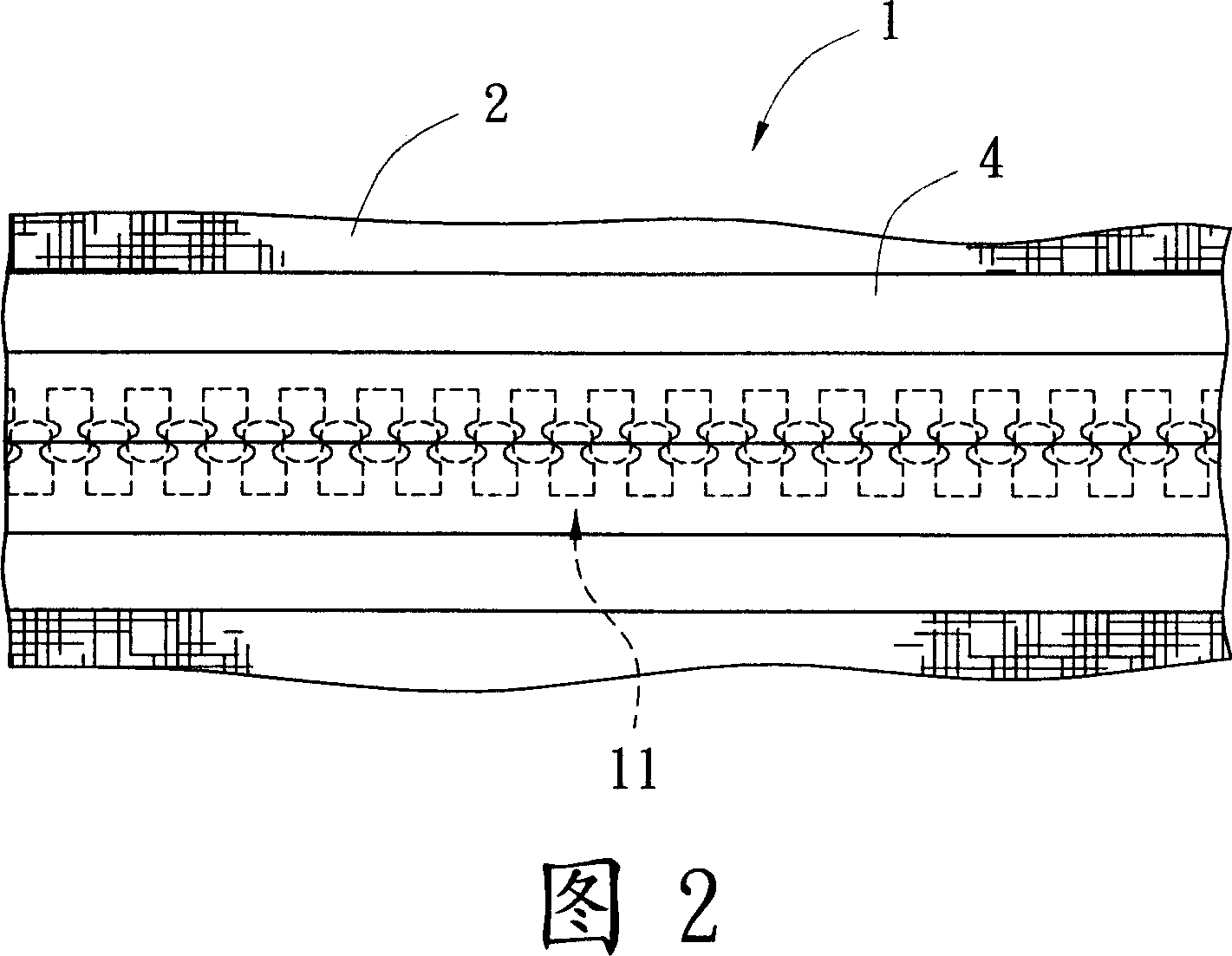

[0026] See also Fig. 1~shown in Fig. 7, it is the preferred embodiment of slide fastener of the present invention and manufacturing method thereof, wherein, the manufacturing method of this slide fastener comprises the following steps:

[0027] a. Provide a zipper 1 with two cloth straps 2 .

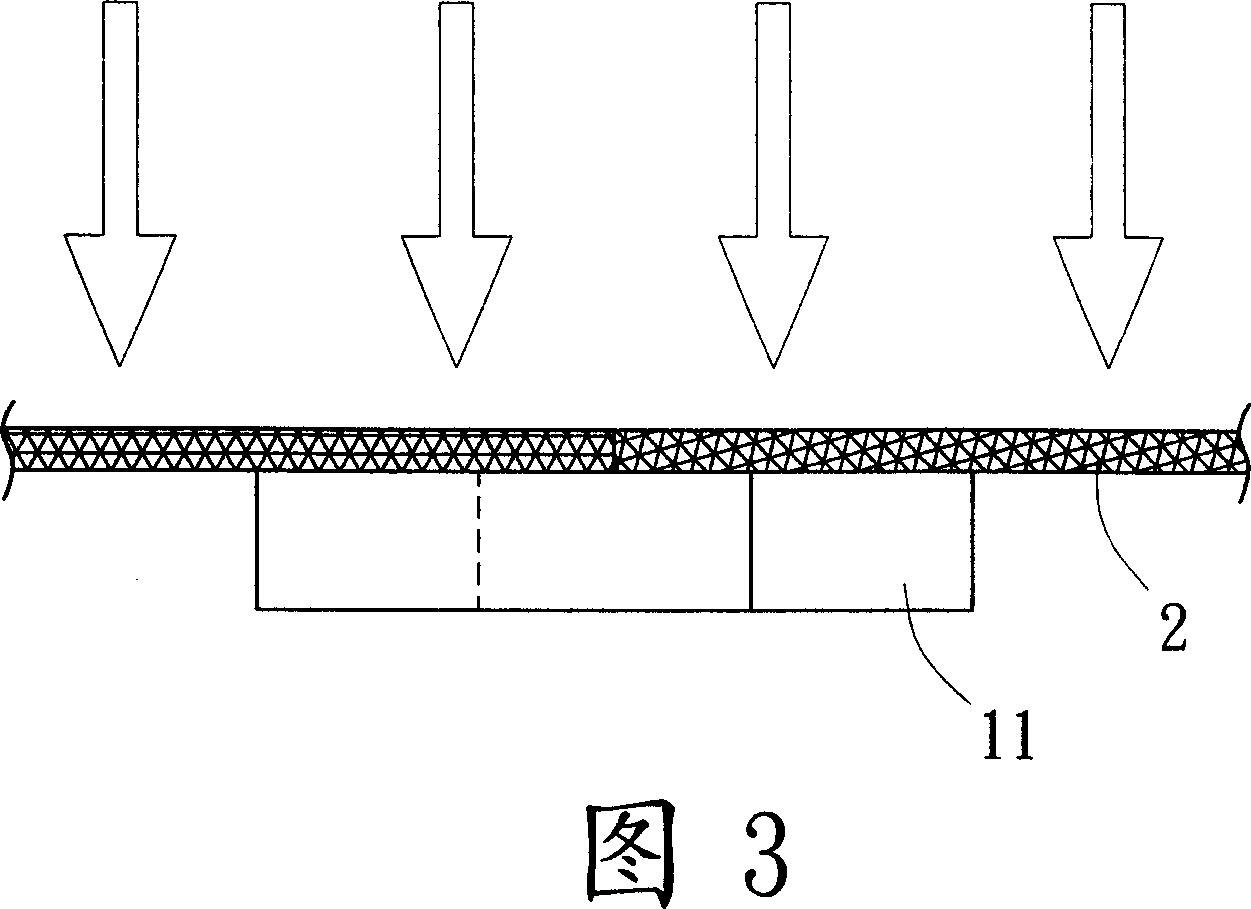

[0028] b. Apply a liquid polymer on the surface of the tape 2 of the zipper 1 so that the liquid polymer penetrates into the tape 2 . as well as

[0029] c. The liquid polymer is solidified to form the waterproof layer 3 .

[0030] In step b, the liquid polymer is PVC (polyvinyl chloride) containing plasticizer or polyester solvent, PU (polyurethane) material or silica gel material, and the PU (polyurethane) material can be single liquid or double liquid type. When the liquid polymer is coated on the surface of the zipper 1 tape 2 by screen printing or dripping, the liquid polymer can directly penetrate between the fibers of the cloth tape 2 and solidify at room temperature to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com