Manganese series deoxidants and their prepn process

A deoxidizer, manganese-based technology, used in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult to achieve ideal requirements, narrow application range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

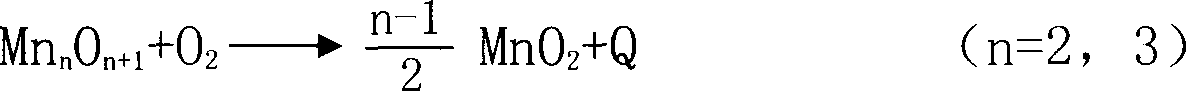

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment manganese series deoxidizer is made up of the following components by weight percentage (with the sum of active component, support carrier, binding agent part amount being 100%):

[0035] MnO 2 40%, 4A molecular sieve 30%, attapulgite 30%, and lignin accounts for MnO 2 10% of the total weight of the mixture of 4A molecular sieve and attapulgite.

[0036] The present embodiment manganese series deoxidizer is made by following method:

[0037] (1), the MnO of described portion 2 , 4A molecular sieve, attapulgite and lignin are mixed evenly, and crushed into a powder of more than 300 mesh;

[0038] (2), the powder rolling ball molding of (1) step;

[0039] (3) Calcining the mixture formed in step (2) at 300-400° C. for 3-5 hours to obtain the manganese-based deoxidizer.

Embodiment 2

[0041] The present embodiment manganese series deoxidizer is made up of the following components by weight percentage (with the sum of active component, support carrier, binding agent part amount being 100%):

[0042] MnO 2 35%, 5A molecular sieve 15%, kaolin 50%, and lignin accounts for MnO 2 15% of the total weight of the mixture of 5A molecular sieve and kaolin clay.

[0043] The present embodiment manganese series deoxidizer is made by following method:

[0044] (1), the MnO of described portion 2 , 5A molecular sieve, kaolin and lignin are mixed evenly, and crushed into a powder of more than 300 mesh;

[0045] (2), the powder compression molding of (1) step;

[0046] (3) Calcining the mixture formed in step (2) at 400-450° C. for 3-5 hours to obtain the manganese-based deoxidizer.

Embodiment 3

[0048] The present embodiment manganese series deoxidizer is made up of the following components by weight percentage (with the sum of active component, support carrier, binding agent part amount being 100%):

[0049] MnCO 3 30%, 13X molecular sieve 50%, diatomaceous earth 20%, and lignin accounts for MnCO 3 , 5% of the total weight of the mixture of 13X molecular sieve and diatomaceous earth.

[0050] The present embodiment manganese series deoxidizer is made by following method:

[0051] (1), the MnCO of described portion 3 , 13X molecular sieve, diatomaceous earth and lignin are mixed evenly, and crushed into a powder of more than 300 mesh;

[0052] (2), the powder rolling ball molding of (1) step;

[0053](3) Calcining the mixture formed in step (2) at 400-500° C. for 3-5 hours to obtain the manganese-based deoxidizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com