Process of making mulberry sparkling wine

A manufacturing method and technology of sparkling wine, applied in the preparation of alcoholic beverages, etc., can solve the problems that the quality of aroma and taste is greatly affected, the stability and quality of wine are affected, and the production cycle is long, so as to achieve shortened production cycle, low cost, and improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

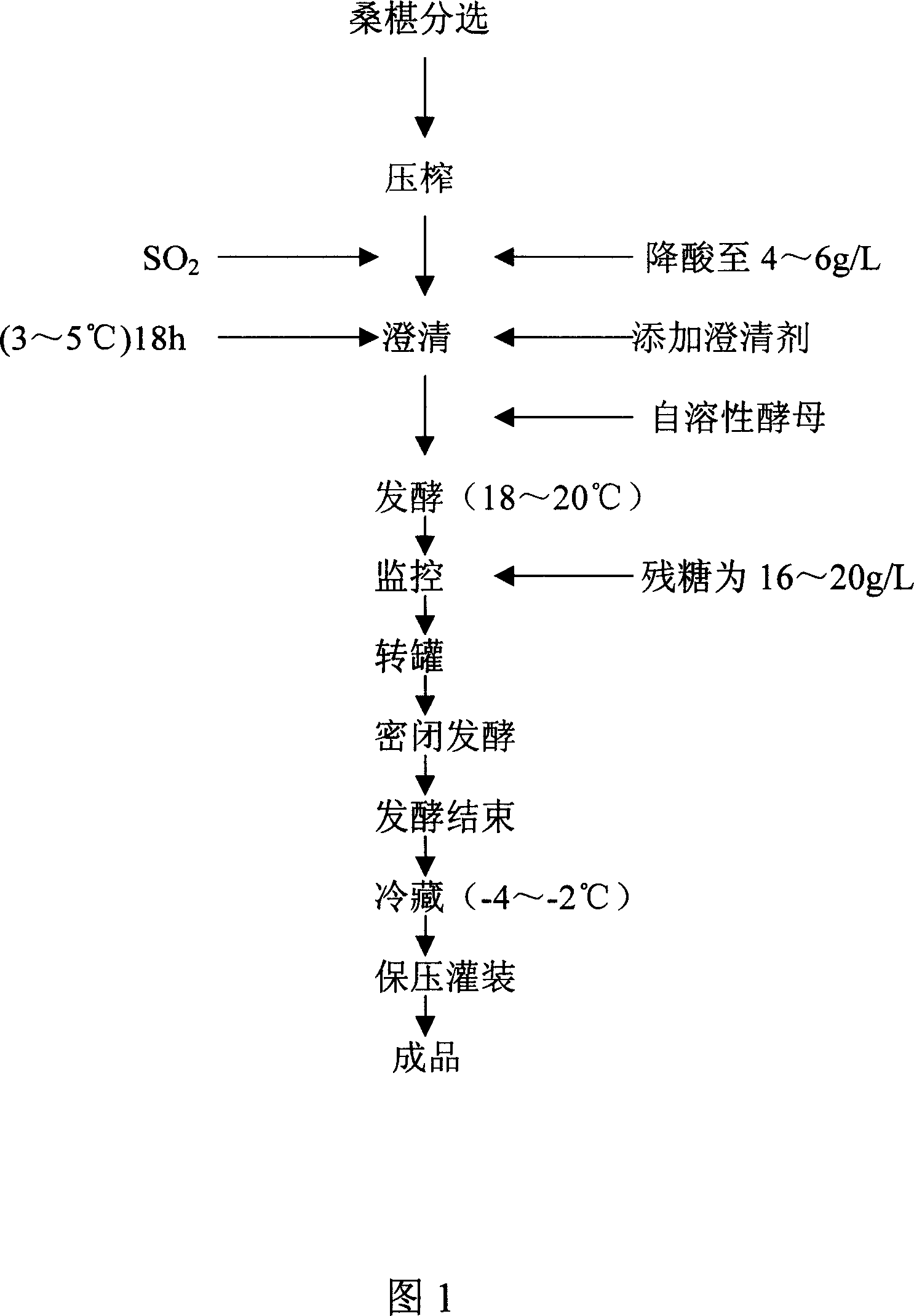

[0015] Embodiment 1: Referring to Fig. 1, use 100 tons of Hongguo No. 2 mulberry varieties as winemaking raw material, and control its maturity (sugar content 90g / L, acid content 6.0~8.0g / L, (tartaric acid)). Remove branches, leaves, rotten fruit, stiff fruit and raw green fruit, send them to the press with a flat feeder for direct pressing, and add SO to the mulberry juice 2 80mg / L (80L H 2 SO 3 (6%)), and with KHCO 3 The total acid of mulberry juice is adjusted to 4.0~6.0g / L, then, at low temperature (3~5 ℃), let stand and clarify for 18 hours, separate clarified mulberry juice into the fermenter, and add 0.2% of autolyzable yeast, Ferment at 18-20°C, transfer to a pressure-holding fermenter when the residual sugar reaches 16-20g / L, and carry out airtight fermentation. After fermentation, refrigerate at low temperature (-4-2°C) for 1 months, then pressurized (5.0bar) filling, corking, capping (iron wire), capping, labeling, and packing into storage. It produces 50 tons o...

Embodiment 2

[0016] Embodiment 2: use 100 tons of Hongguo No. 2 mulberry varieties as winemaking raw materials, and control its maturity (sugar content 90g / L, acid content 7.0g / L, (tartaric acid)). Remove branches, leaves, rotten fruit, stiff fruit and raw green fruit, send them to the press with a flat feeder for direct pressing, and add SO to the mulberry juice 2 80mg / L (80L H 2 SO 3 (6%)), and with KHCO 3 The total acid of mulberry juice is adjusted to 5.0g / L, then, at low temperature (4 DEG C), stand and clarify for 18 hours, separate clarified mulberry juice into the fermenter, and add autolyzable yeast 0.2%, at 20 DEG C Fermentation under low temperature, when the residual sugar reaches 18g / L, it is transferred to a pressure-holding fermentation tank for airtight fermentation. After fermentation, it is refrigerated at low temperature (-2°C) for 1 month, and then pressure-holding (5.0bar) is poured Packing, plugging, capping (iron wire), capping, labeling, and then packing into sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com